Auxiliary nozzle for air-jet loom

A technology for auxiliary nozzles and air-jet looms, which is applied in looms, textiles, textiles and papermaking, etc. It can solve the problems of poor injection ability of auxiliary nozzles, achieve strong injection capabilities, reduce air consumption, and maintain stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 Auxiliary nozzle for air-jet loom

[0057] Such as figure 1 As shown, the present embodiment is an auxiliary nozzle for an air-jet loom, including a nozzle seat 1 and a nozzle 2 pierced and installed in the center hole of the nozzle seat 1 . The spray end of the nozzle 2 has a first spray head 3 and a second spray head 4 arranged in parallel, and each of the first spray head 3 and the second spray head 4 is provided with an air spray hole 5, and the direction of the two air spray holes 5 is consistent.

[0058] Depend on figure 2 , image 3 It can be seen that the air injection holes 5 in this embodiment are all rectangular.

[0059] Such as image 3 As shown, the nozzle 2 is provided with an airflow chamber 6, the first spray head 3 is provided with a first airflow passage 7 communicating with the airflow chamber 6, and the second sprayhead 4 is provided with a second airflow passage 7 communicating with the airflow chamber 6. The airflow channel 8,...

Embodiment 2

[0082] Embodiment 2 A kind of air-jet loom

[0083] Such as Figure 11 As shown, the present embodiment is an air-jet loom, including a profiled reed 17 provided with a weft passage 16, a main nozzle 18 facing the starting end of the weft passage 16, and auxiliary nozzles in Embodiment 1 arranged in sequence along the extending direction of the weft passage 16. nozzle.

[0084] In this embodiment, the auxiliary nozzles include a front auxiliary nozzle group 19 and a rear auxiliary nozzle 20 arranged sequentially along the extending direction of the weft passage 16, and each auxiliary nozzle is controlled by an independent solenoid valve.

[0085] Wherein, the front auxiliary nozzle group 19 includes several first auxiliary nozzles 21 , and the rear auxiliary nozzle group 20 includes four second auxiliary nozzles 22 .

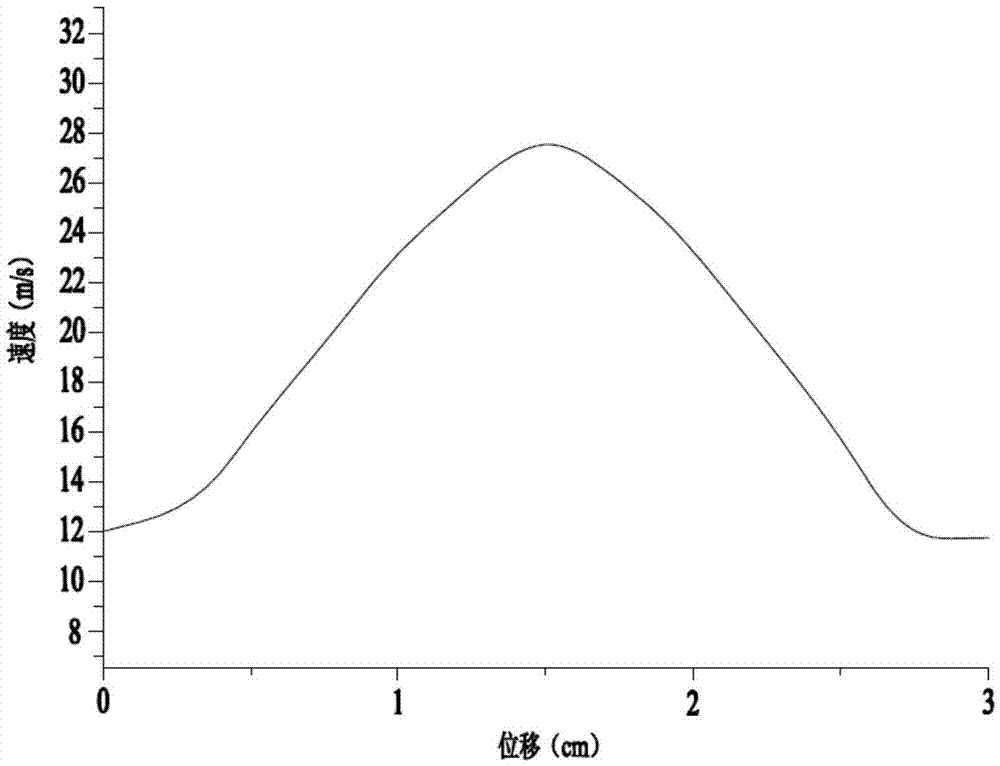

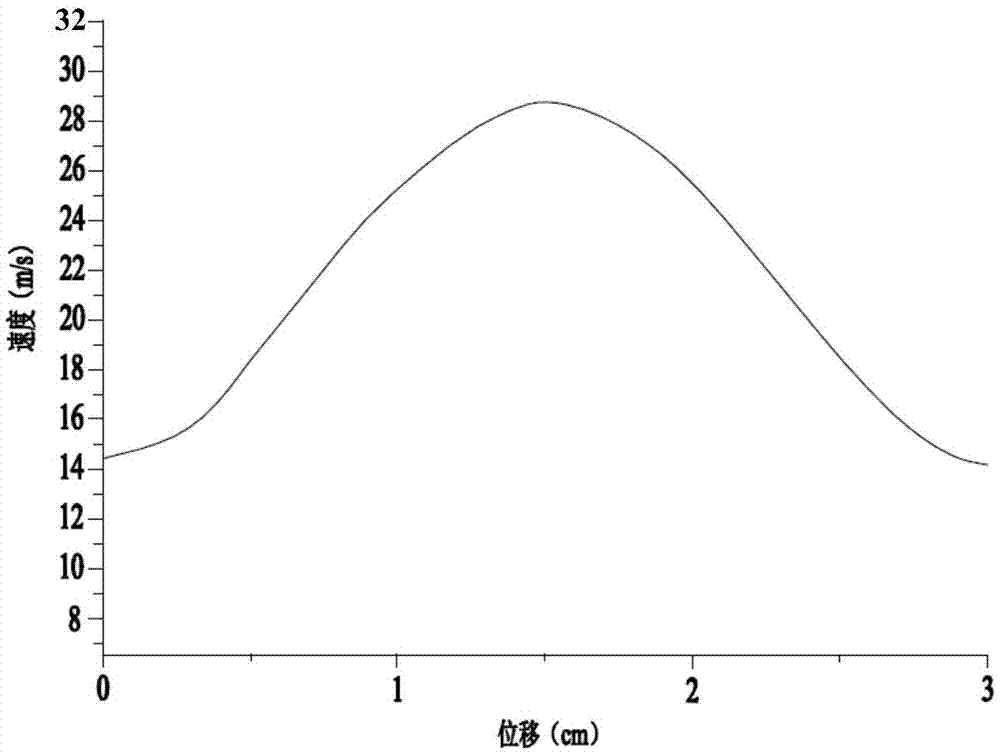

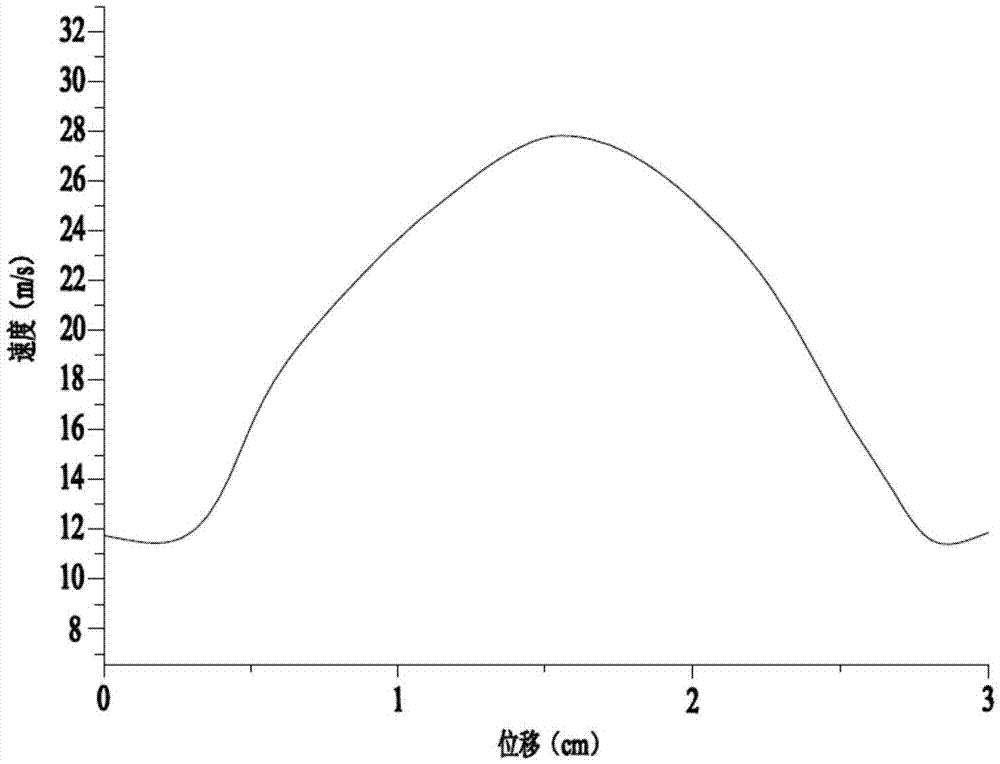

[0086] Since the reasonable arrangement of the auxiliary nozzles can effectively reduce the air consumption in the profiled reed, this embodiment discusses an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com