A kind of production method of compound flavor liquor

A production method and compound aroma technology, which is applied in the field of wine making, can solve the problems of not being able to meet market demand and a single liquor style, and achieve the effects of shortening production time, shortening fermentation time, and improving the quality of wine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

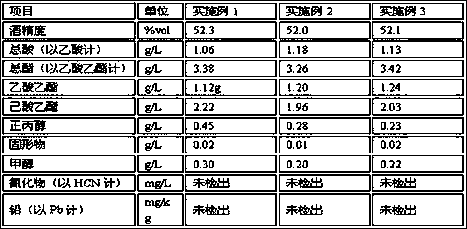

Embodiment 1

[0022] First, add 280kg of 40% Luzhou-flavor liquor fermented grains (fermented for 66 days) and 60% Xiaoqu Fen-flavor liquor fermented grains (for 7 days), and add 156kg (1:4.5) of crushed sorghum (passed through a 70-mesh sieve). ), mix evenly, moisten the grain for 40 minutes, then add 20% husk, about 31.2kg, mix evenly, and start to put the steamer on. After the retort is finished, distill the wine first. The time for the first stage of distilling is 15 minutes. The wine tail should be cut off when the flower is broken, and the tail should be cut off when the oil flower is full. The time will take about 35 minutes. After the tail is docked, the firepower should be increased to steam the grain to promote the gelatinization of the raw material starch and achieve the purpose of acidification. The distilled raw wine is graded and stored in an altar. The total time for steaming grain is 70 minutes. When the steamer comes out, the ingredients are soft and not greasy. There is no...

Embodiment 2

[0025] First, add 280kg of 42.5% Luzhou-flavor liquor fermented grains (66 days of fermentation) and 420kg of 57.5% Xiaoqu Fen-flavor liquor fermented grains (7 days of fermentation), and add 147kg ((1:4.75)) of crushed sorghum (over 70 Mesh sieve), mix evenly, moisten the grain for 40 minutes, then add 22% husk, about 32.3kg, mix evenly, and start to put the steamer on. Pay attention, spread lightly and evenly, and put the steamer on the air. After the retort is finished, distill the wine first. The time for the first stage of distilling is 15 minutes. The wine tail should be cut off when the flower is broken, and the tail should be cut off when the oil flower is full. The time will take about 35 minutes. After the tail is docked, the firepower should be increased to steam the grain to promote the gelatinization of the raw material starch and achieve the purpose of acidification. The distilled raw wine is graded and stored in an altar. The total time for steaming grain is 65 ...

Embodiment 3

[0028] Add 280kg of 45% Luzhou-flavor liquor fermented grains (66 days of fermentation) and 420kg of 55% Xiaoqu Fen-flavor liquor fermented grains (7 days of fermentation), add 140kg (1:5) of crushed sorghum (passed through a 70-mesh sieve) ), mix evenly, moisten the grain for 40 minutes, then add 24% of the husk, about 33.6kg, mix evenly, start the steamer, pay attention, spread lightly, and put the steamer on the air. After the steamer is finished, distill the wine first The time for the first stage of distilling wine is 15 minutes. When the flower is broken, the tail of the wine should be intercepted, and the tail should be cut off when the oily flower is full. The time is about 35 minutes. After the tail is cut, the firepower should be increased to steam the grain to promote the gelatinization of the raw material starch and achieve For the purpose of souring, the distilled raw wine is graded and stored in altars. The total time of steaming grain is 60 minutes. The raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com