Working method for sorting device for bearing rings

A bearing ring and sorting device technology, applied in sorting and other directions, can solve the problem of large area of the sorting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

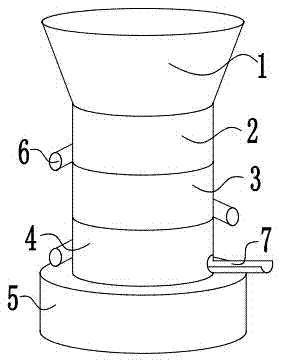

[0025] Instructions attached figure 1 The reference signs in include: hopper 1 , outer diameter detection layer 2 , channel detection layer 3 , surface detection layer 4 , motor 5 , discharge pipe 6 , and delivery tank 7 .

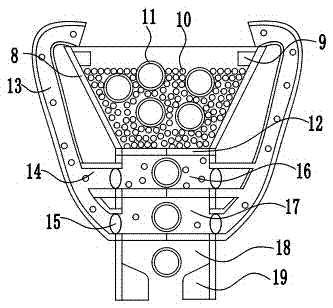

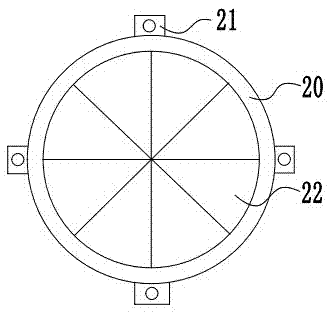

[0026] Such as figure 1 As shown, the sorting device for bearing rings includes hopper 1, outer diameter detection layer 2, channel detection layer 3, surface detection layer 4 and motor 5 connected from top to bottom, hopper 1, outer diameter detection layer 2. The channel detection layer 3 and the surface detection layer 4 are connected with circular spacers as the top and bottom plates of each layer. The top and bottom panels of each level are connected within the tubular side walls. The outer diameter detection layer 2, the channel detection layer 3 and the surface detection layer 4 all pass through the side wall and communicate with a discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com