Device and method for quantitatively taking liquid seasonings

A technology for condiments and liquids, which is applied to the field of quantitative taking devices for liquid condiments, can solve the problems of high cost, difficulty in controlling oil quantity, complicated structure and the like, and achieves the effects of low cost, simple structure and accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

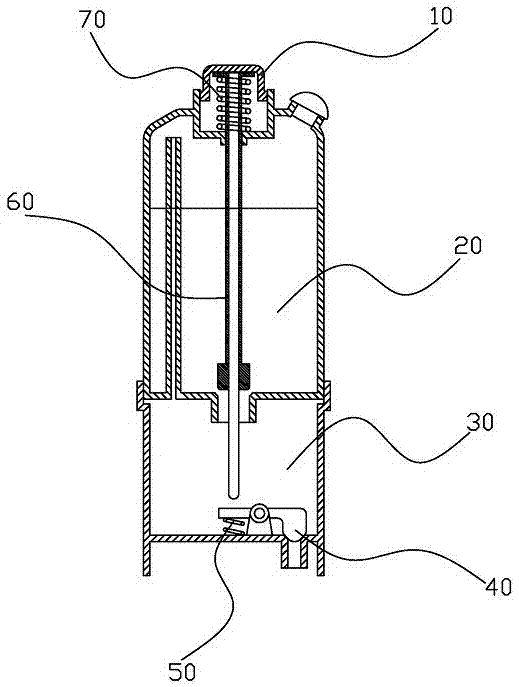

[0021] In order to facilitate a further understanding and understanding of the features and functions of the present invention, the following will be attached in conjunction with the specification figure 1 And figure 2 The detailed structure and design concept of the present invention are described, and the detailed statement is as follows:

[0022] A liquid condiment quantitative taking device, comprising: a liquid withdrawal button 10, a liquid reservoir 20, a liquid extractor 30, a liquid outlet shut-off valve assembly 40, a liquid outlet shut-off valve assembly spring 50, and a liquid reservoir shut-off valve assembly 60. Take the liquid button spring 70. The accumulator 20 and the liquid extractor 30 are formed as a whole by threading, bonding or other connection methods. There is a communication port between the liquid accumulator 20 and the liquid extractor 30; the liquid accumulator 20 includes a liquid injection port, For injecting liquid condiments, the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com