Grounding drill rod for power construction operation

A technology of electric power construction and grounding brazing, which is applied in the direction of connecting contact materials, etc., can solve the problems that the grounding brazing is easy to be nailed by a hammer, and the grounding brazing is difficult to pull out and drive in, so as to achieve the effect of not being loose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

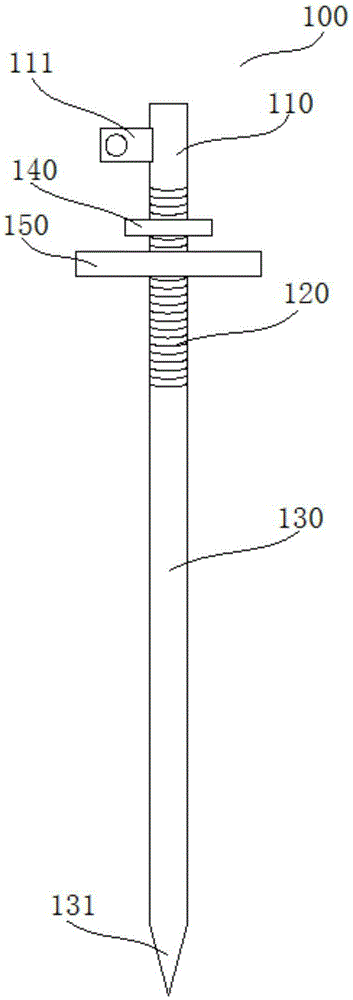

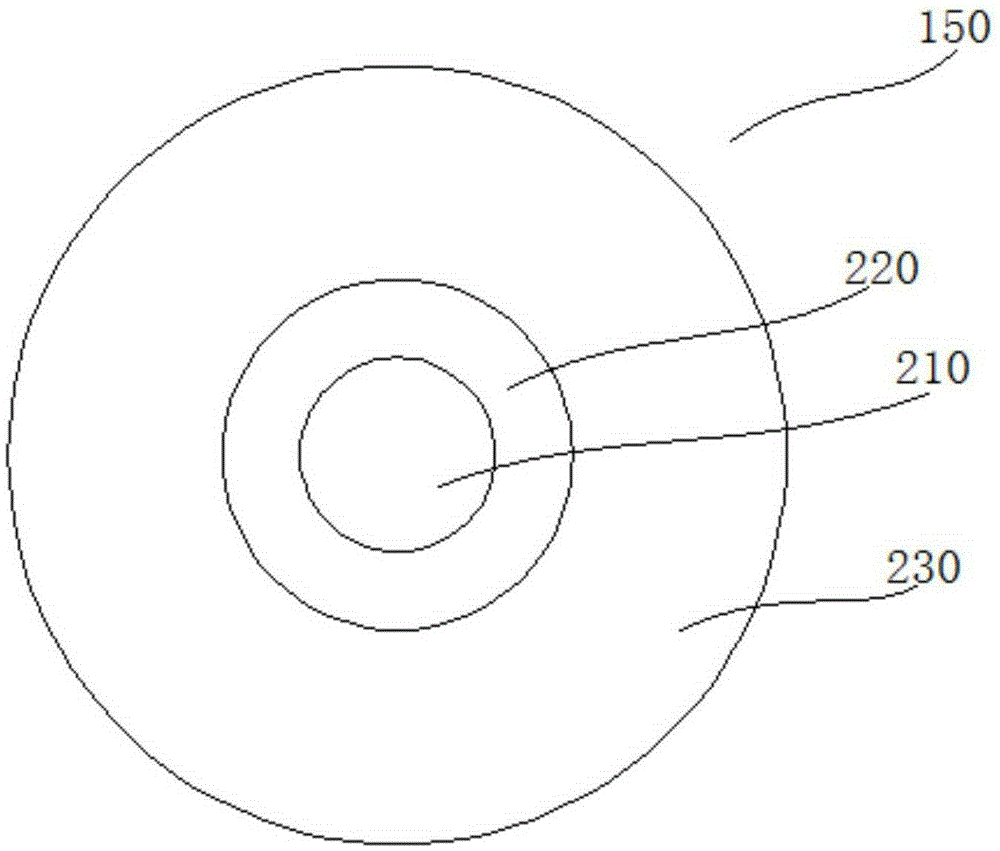

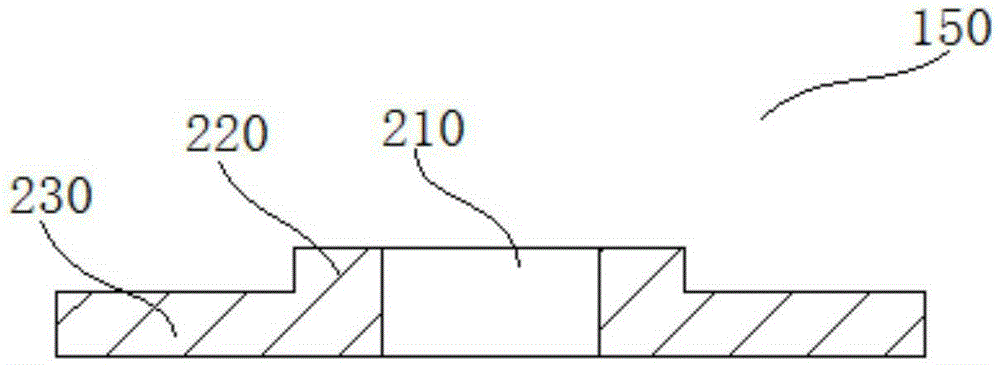

[0059] Such as figure 1 As shown, this embodiment provides a grounding solder used in electric power construction, which includes a columnar solder body 100 . Wherein, the drill body 100 is sequentially composed of a wiring section 110, a threaded section 120, and a polished rod section 130 from top to bottom. The threaded section 120 is threadedly connected with a pull-out nut 140. Fitting tablet 150 .

[0060] In this embodiment, the connection section 110 is provided with a connection terminal 111, and the lower end of the polished rod section 130 is gradually reduced to form a tapered insertion end 131 with a taper of 1:11. The outer diameter of the polished rod section 130 is 0.1 mm larger than that of the threaded section 120. , the length ratio of the threaded section to the polished rod section can be 1:1, the surface of the threaded section 120 is carburized with a carburized layer with a thickness of 0.2, and the surface of the polished rod section 130 is nitrided w...

Embodiment 2

[0063] This embodiment provides a grounding solder used in electric power maintenance operations, which differs from Embodiment 1 in that: Figure 4 As shown, it is a schematic cross-sectional view of the polished rod section 130 in this embodiment. The polished rod section 130 is provided with 6 excavation grooves 410 uniformly distributed along the axial direction, and the depth of the excavation grooves 410 gradually becomes deeper from top to bottom. The deepest depth of 410 is 0.2-0.3 of the outer diameter of the polished rod section.

[0064] In addition, in this embodiment, the length ratio of the threaded section and the polished rod section can be 3:1, the surface of the threaded section 120 is carburized to form a carburized layer with a thickness of 0.5 mm, and the surface of the polished rod section 130 is formed by nitriding. The thickness of the nitrided layer is 0.6 mm, and the outer diameter of the pressed sheet 150 is 5 times the outer diameter of the polished...

Embodiment 3

[0066] This embodiment provides a grounding solder used in the distribution network lightning protection system, which differs from Embodiment 1 in that: Figure 5 As shown, it is a schematic cross-sectional view of the polished rod segment 130 in this embodiment. The side wall of the polished rod segment 130 is provided with four ribs 510 along the axial direction, and the cross-section of each rib 510 is configured as a triangle.

[0067] In addition, in this embodiment, the length ratio of the threaded section to the polished rod section can be 2:1, the surface of the threaded section 120 is carburized to form a carburized layer with a thickness of 0.3 mm, and the surface of the polished rod section 130 is formed by nitriding. The thickness of the nitrided layer is 0.4 mm, and the outer diameter of the pressed sheet 150 is 4 times the outer diameter of the polished rod section 130 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com