Online measurement device and method for boiler pulverized coal particle parameters

A measurement device and particle technology, applied in the direction of analyzing materials, instruments, etc., can solve problems such as large changes in physical parameters, and achieve the effects of simple implementation, high sensitivity, and improved reliability and measurement sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structure of the on-line measurement device for pulverized coal parameters of power plant boilers combined with dual laser sensors of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Those skilled in the art should understand that the embodiments described below are only illustrative illustrations of the present invention, and are not intended to limit it in any way.

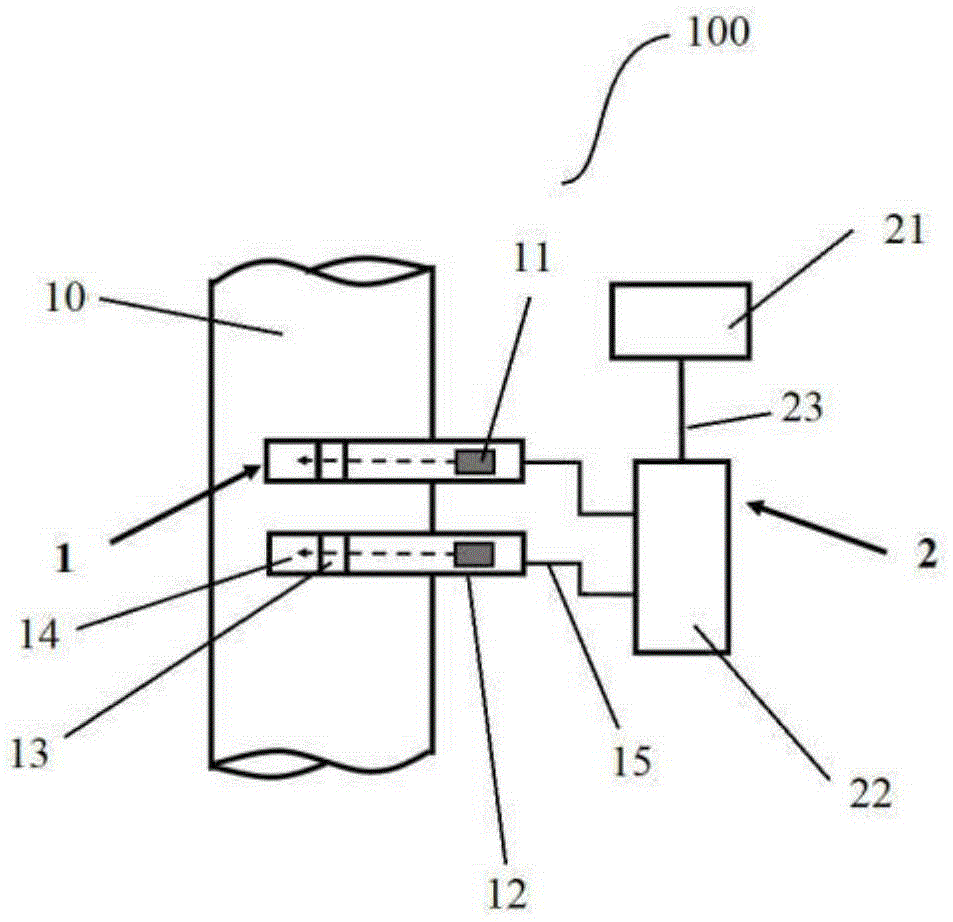

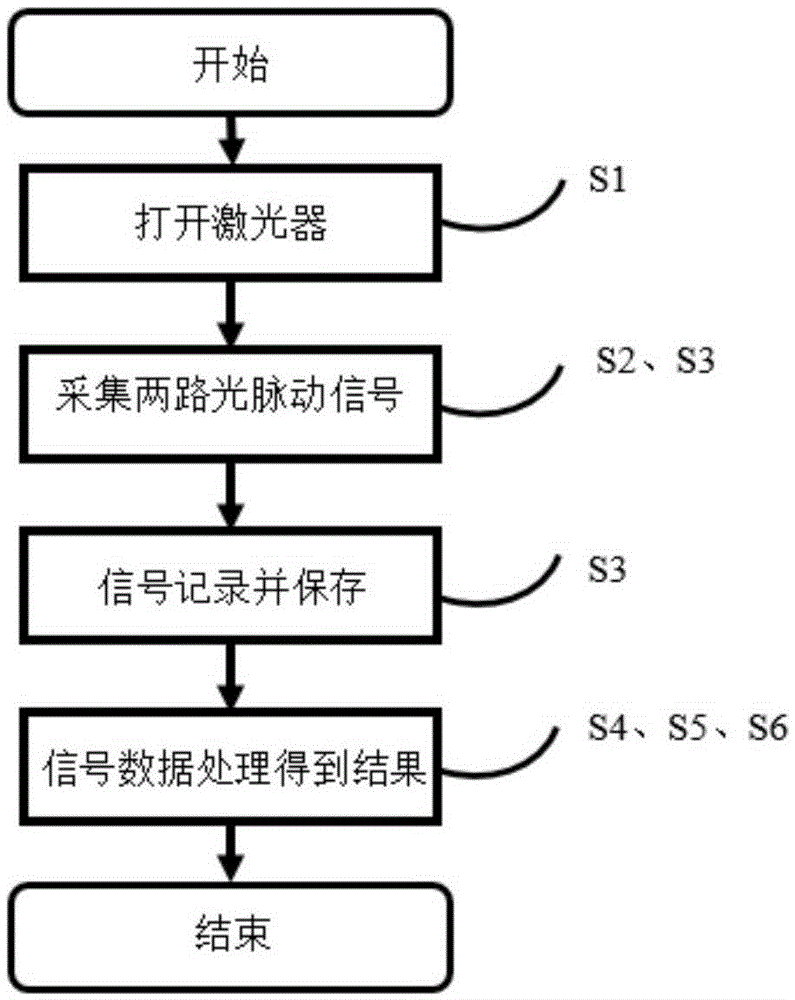

[0032] figure 1 It is a structural schematic diagram of an on-line measuring device for pulverized coal parameters of a power plant boiler combined with dual laser sensors of the present invention. The measuring device is used to measure the particle size, concentration and velocity of pulverized coal particles in the pulverized coal pipeline of the power plant boiler.

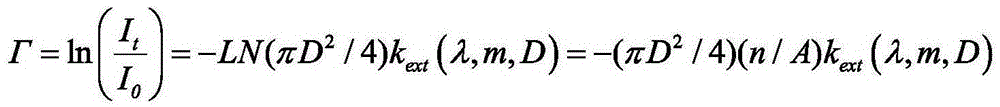

[0033] Such as figure 1 As shown, the on-line measurement device 100 for pulverized coal parameters of a power plant boiler combined with dual laser sensors includes an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com