A Distributed Optical Fiber Curvature Sensor

A curvature sensor and distributed optical fiber technology, applied in the field of sensors, can solve the problems of inability to measure continuously, less locations for curvature measurement, restricting the application range, etc., to achieve improved range and adaptability, small mode capacity, and avoid inter-mode crosstalk Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiment of the present application provides a distributed optical fiber curvature sensor to solve the technical problem that the curvature measurement position in the prior art is small and cannot be continuously measured, which seriously restricts the scope of application. The measurement becomes possible, which makes the fiber optic curvature sensor have a wider application scenario.

[0039] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

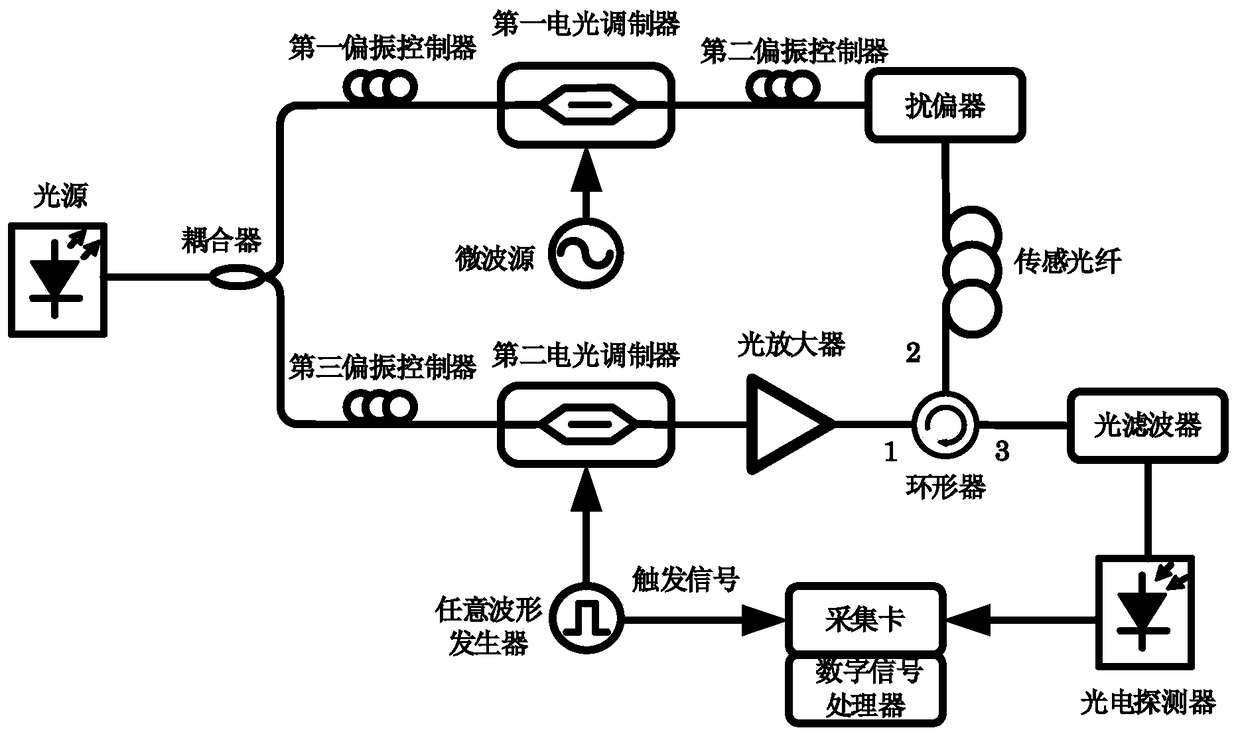

[0040] A distributed optical fiber curvature sensor, comprising: a frequency modulation unit, a pulse modulation unit, a sensing fiber, a light source, and an optical signal processing unit;

[0041] The light source is respectively connected with the frequency modulation unit and the power adjustment unit to output optical signals;

[0042] The frequency modulation unit is connected to the first end of the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com