Measurement tool for controlling uniformity of coating layer of casing

A technology for measuring tooling and controlling machines, applied in the direction of mechanical thickness measurement, mechanical diameter measurement, etc., can solve problems such as scraping between rotor blades and local coatings, affecting the working quality of the engine, and eccentricity of the inner diameter of the casing coating, so as to improve manufacturing , shorten the assembly turnover cycle of parts, and improve the effect of coating repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

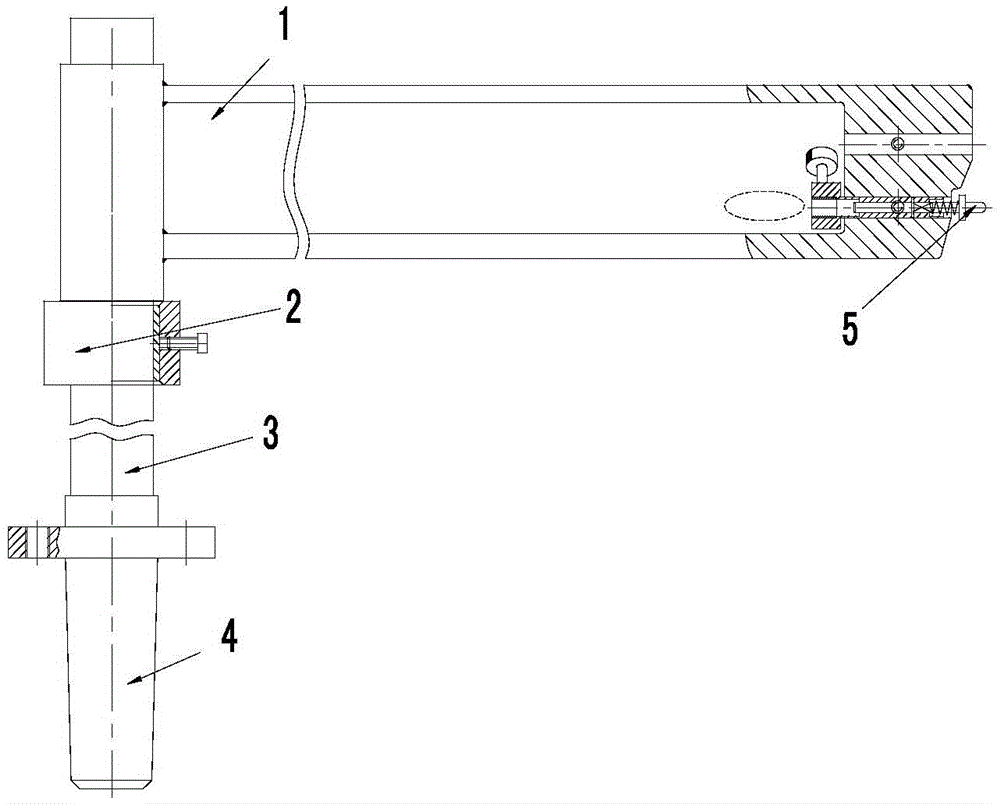

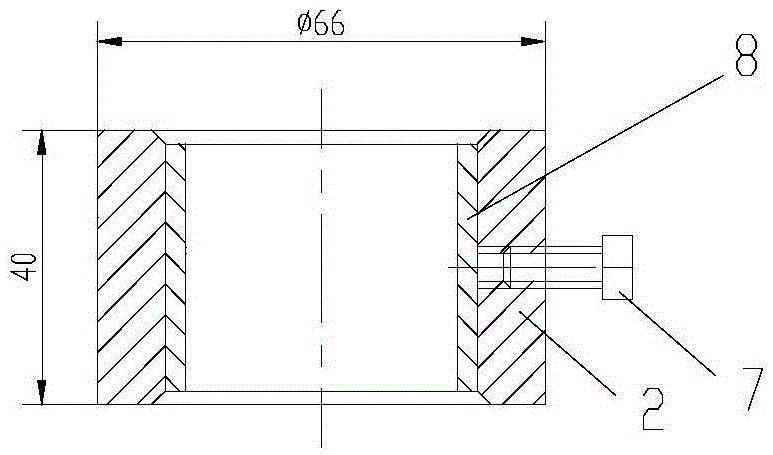

[0029] Such as figure 1 As shown, the coating radius measurement tool is mainly composed of multiple independent tools such as the measuring rod (the measuring rod mandrel 3, the measuring rod seat 4), the positioning ring 2, and the measuring tool (the measuring arm 1, the measuring head 5). The structure is as follows:

[0030] The measuring rod mandrel 3 is installed on the measuring rod seat 4 of the measuring rod, and the positioning ring 2 is arranged on the measuring rod mandrel 3; The position is positioned, and the other end of the measuring arm 1 is installed with the measuring head 5. The measuring tool is the main load-bearing and rotating part, and the basic limit device for coating radius measurement.

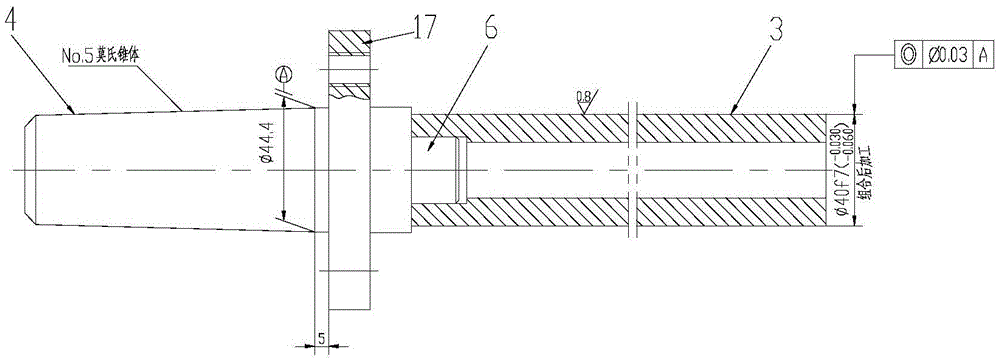

[0031] Such as figure 1 , figure 2 As shown, the top of the measuring rod base 4 is provided with a positioning platform 6, the measuring rod base 4 is provided with a flange 17, the measuring rod base 4 is installed on the fixture base through the flange 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com