Gas drainage pipeline environment simulation device

An environmental simulation device and gas drainage technology, applied in gas discharge, safety devices, mining equipment, etc., can solve the problem of high risk, inability to simulate the gas drainage pipeline environment, and inability to analyze the flow of gas and cinder in detail, etc. problem, to achieve the effect of optimizing the design scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

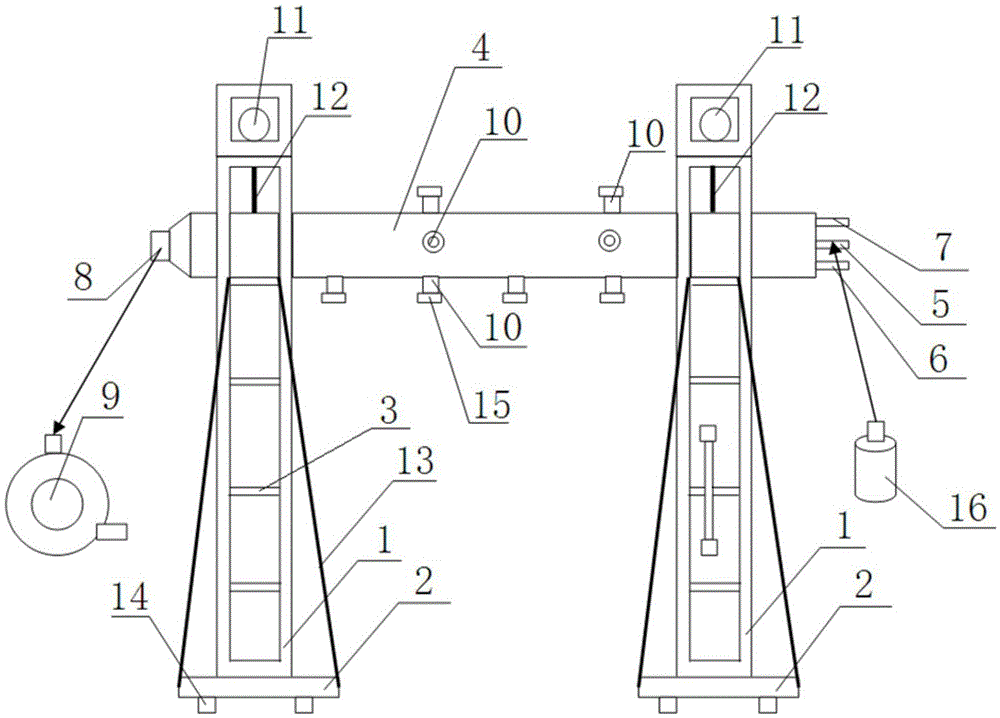

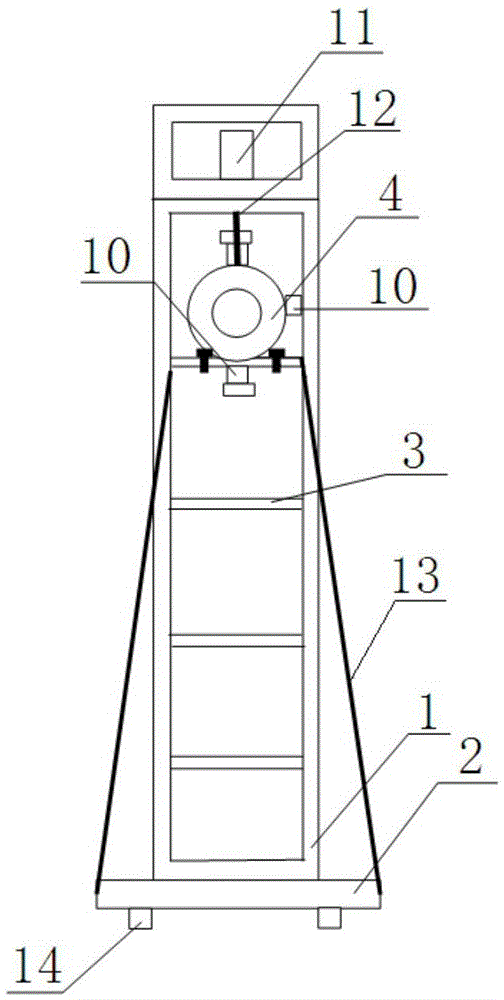

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] like figure 1 , figure 2 As shown, the present invention includes two vertical beams 1 arranged at intervals, and a base 2 is fastened to the lower end of each vertical beam 1 . A plurality of pairs of rams 3 are arranged at intervals up and down on the two vertical beams 1 , and each ram 3 is slidably connected in a vertical chute on the vertical beam 1 . A plurality of bolt holes are uniformly arranged up and down on each vertical beam 1 , and the ram 3 stops at the predetermined height of the vertical beam 1 through a bolt hole passing through the vertical beam 1 and its own bolt. In the present invention, one or more gas pipelines 4 can be set according to the experimental content, and the diameters of the gas pipelines 4 are different. Each gas pipeline 4 is supported on a pair of rams 3 at the same height. Both ends of the gas pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com