Multilayer carbon cloth stitching device

A technology of sewing device and carbon cloth, which is applied in sewing machine control device, cloth feeding mechanism, sewing equipment, etc., can solve the problems of increasing production cycle, reducing labor efficiency, increasing production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

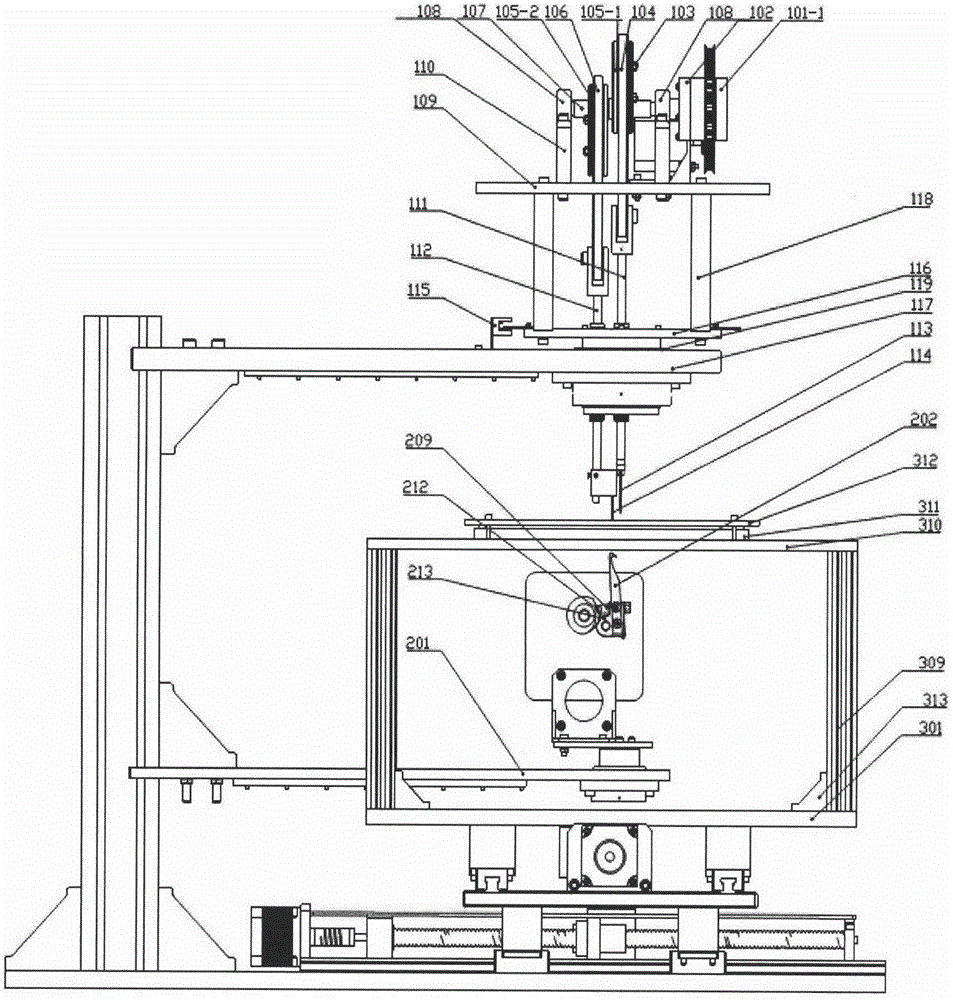

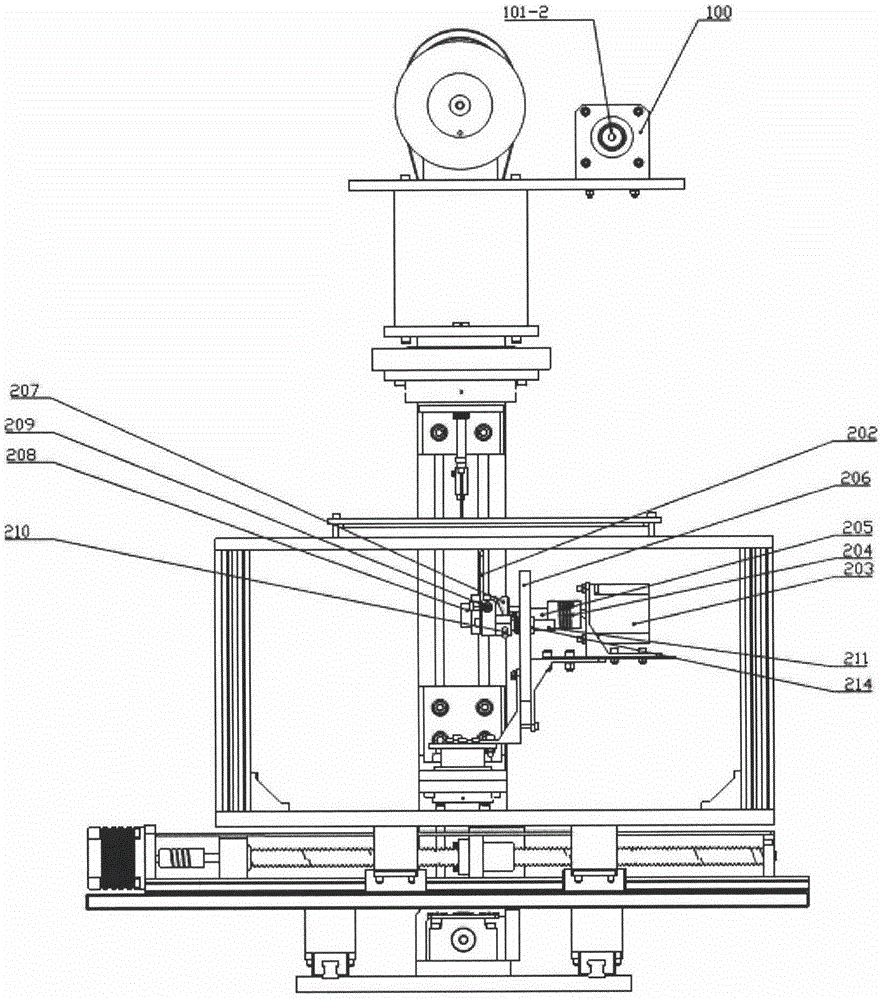

[0041] Such as figure 1 As shown, the multi-layer carbon cloth sewing device includes the main shaft (107) of the acupuncture mechanism (109) for pre-punching and sewing needle planting, driven by the stepper motor 1 (100) to drive the pulley set (101-1 -2) to drive the main shaft to rotate, and the rotation simultaneously drives the two eccentric wheels (105-1-2) to reciprocate up and down, the two are connected by keys, and the two eccentric wheels (105-1-2) respectively drive There are connecting rod 1 (104) and connecting rod 2 (106), the connecting rods are connected with the needle bars, one is the needle-planting needle bar (111), the other is the pre-punching needle bar (112), and drives the two needle bars Reciprocating up and down, the phase difference between the two is 90 degrees, the needle planting needle (113) is provided on the needle planting needle bar (111), and the pre-punching needle (114) is provided on the pre-punching needle bar (112). The acupuncture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com