Novel stand column type cantilever crane

A column-type and crane technology, which is applied to cranes and other directions, can solve the problems that the position of the column-type cantilever crane cannot be moved, the cantilever and column are not easy to disassemble, and the scope of use is limited. material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

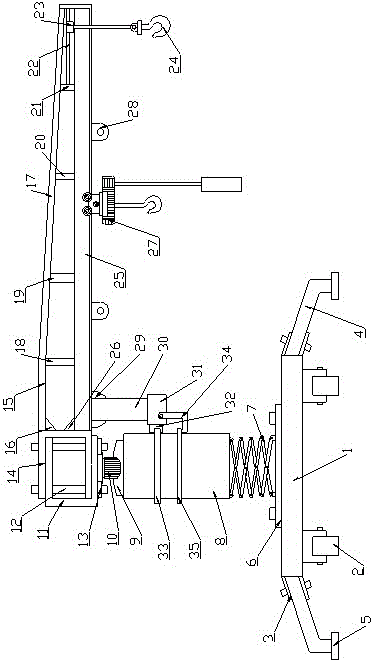

[0016] Such as figure 1 As shown, a novel column type cantilever crane includes a base 1, the lower side of the base 1 is provided with a universal sliding wheel 2, the four corners of the base 1 are provided with connecting plates 3, and the connecting plates 3 The legs 4 are connected by bolts, the bottom of the legs 4 is provided with a non-slip base 5, and the upper side of the base 1 is connected with a lifting platform 6 and a lifting device 7 matched with the lifting platform 6 through bolts. The upper end of the lifting device 7 is connected with a column 8, and the upper end of the column 8 is provided with a motor fixing seat 9 and a driving motor 10 matched with the motor fixing seat 9. The driving motor 10 is connected with a fixing buckle A11, and the fixing The buckle A11 is provided with a through hole matched with the output shaft of the drive motor 10, and the upper and lower parts of the fixed buckle A11 are provided with threaded holes, and the fixed buckle ...

Embodiment 2

[0019] Such as figure 1As shown, a novel column type cantilever crane includes a base 1, the lower side of the base 1 is provided with a universal sliding wheel 2, the four corners of the base 1 are provided with connecting plates 3, and the connecting plates 3 The legs 4 are connected by bolts, the bottom of the legs 4 is provided with a non-slip base 5, and the upper side of the base 1 is connected with a lifting platform 6 and a lifting device 7 matched with the lifting platform 6 through bolts. The upper end of the lifting device 7 is connected with a column 8, and the upper end of the column 8 is provided with a motor fixing seat 9 and a driving motor 10 matched with the motor fixing seat 9. The driving motor 10 is connected with a fixing buckle A11, and the fixing The buckle A11 is provided with a through hole matched with the output shaft of the drive motor 10, and the upper and lower parts of the fixed buckle A11 are provided with threaded holes, and the fixed buckle A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com