Kelp slitter

A shredding machine and kelp technology, which is applied in metal processing and other directions, can solve problems such as affecting shredding efficiency and existing safety hazards, and achieve the effects of simple structure, safe use and high shredding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

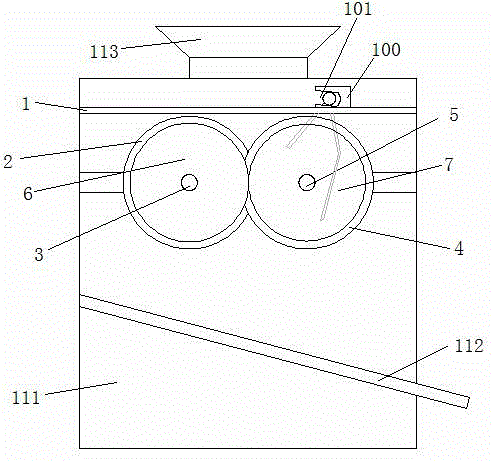

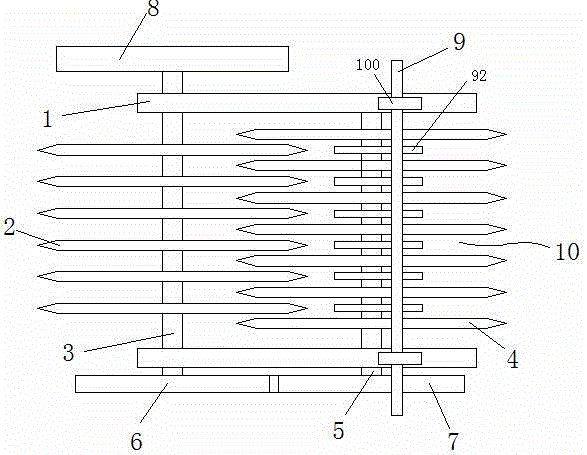

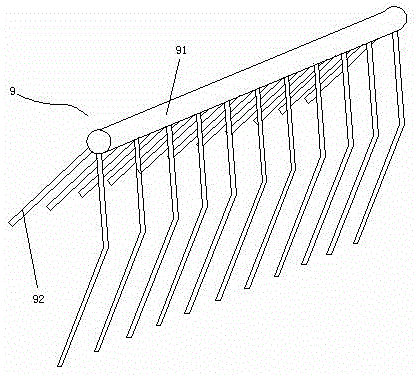

[0018] Such as figure 1 Shown, a kind of kelp shredding machine of the present invention, box body 111, is provided with feed inlet 113 at the top of box body 111, is provided with guide plate 112 inclinedly in the inner chamber of box body 111, and the material guide plate 112 The lower end extends out of the box body 111 . A first blade shaft 3 and a second blade shaft 5 are rotated in the casing 111, and the first blade shaft 3 and the second blade shaft 5 are parallel to each other.

[0019] The first transmission gear 6 and the second transmission gear 7 are respectively fixedly connected to the corresponding ends of the first blade shaft 3 and the second blade shaft 5, and the first transmission gear 6 is meshed with the second transmission gear 7, and the transmission pulley 8 is fixedly connected At the other end of the first blade shaft 3, the transmission p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com