Improved type universal fixture for machining blade profile

A blade profile and improved technology, applied in manufacturing tools, metal processing equipment, metal processing machine parts, etc., can solve the problem of long time for replacement of blade tenon fixing seat or mold block, long time for debugging of blade tenon, crushing of blade tenon, and fixture positioning time It can solve the problem of inaccurate positioning, improve the processing quality, and stabilize the point or line contact method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The improved universal jig for processing blade profiles of the present invention will be further described below through examples and with reference to the accompanying drawings. In the following embodiments, the self-centering two-jaw chuck of model 200 (manufactured by Chengdu Hangfeng Company) is selected as the self-centering two-jaw chuck, and the positioning structure is processed on the top surface of the jaws.

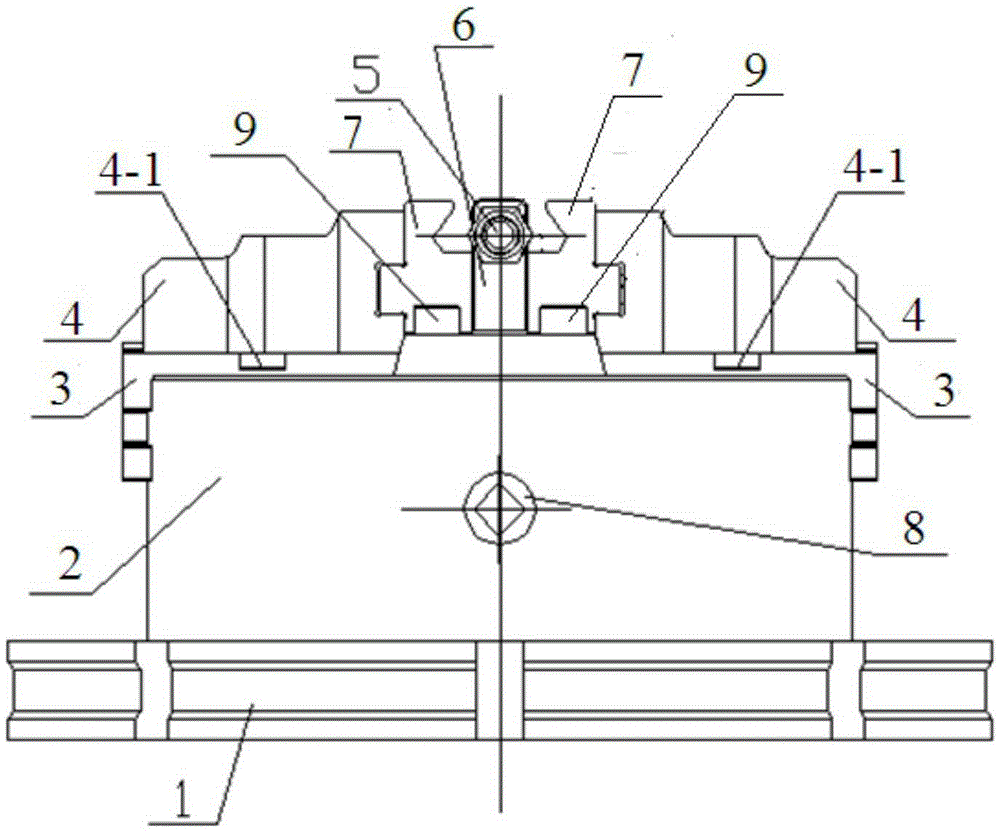

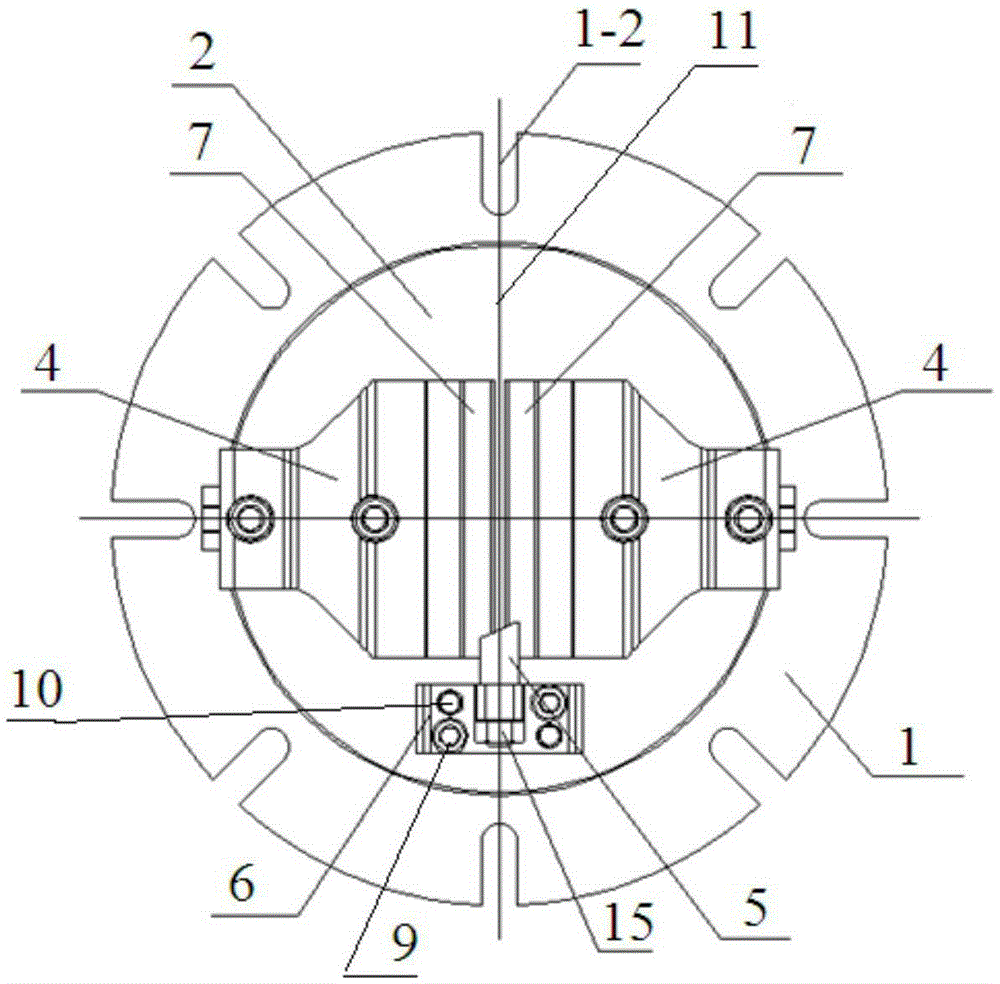

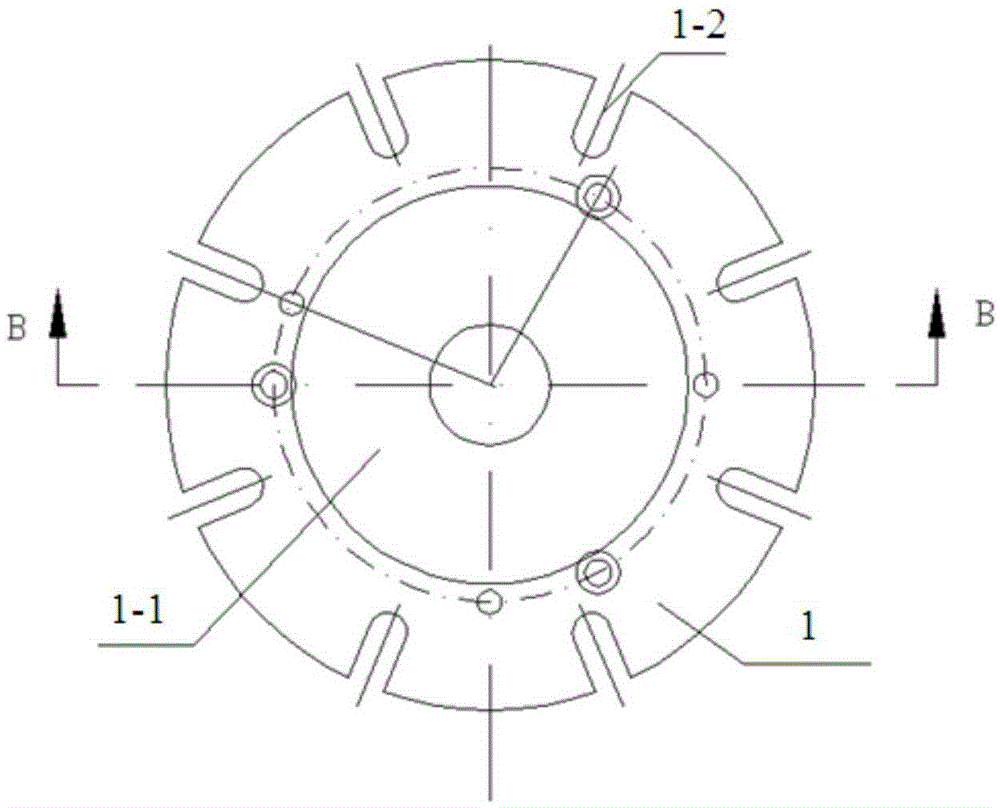

[0054] The improved universal fixture for processing blade profiles described in this embodiment has a structure such as figure 1 , figure 2 As shown, it includes base 1, self-centering two-jaw chuck 2, block 7, block fixing seat 4, positioning seat 6, replaceable positioning rod 5 and the debugging standard for positioning the universal fixture on the milling machine table piece 14. The structure of base 1 is as follows image 3 , Figure 4 As shown, it is a circular seat body, the seat body is provided with a central hole, a sinking through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com