Stevia leaf removal device and processing method thereof

A stevia and sorting device technology, which is applied in chemical instruments and methods, solid separation, and separation of solids from solids with airflow, can solve the problems of stevia sugar production loss, high labor intensity, and large climate impact. To achieve the effect of ensuring sugar production and quality, reducing labor intensity and reducing drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

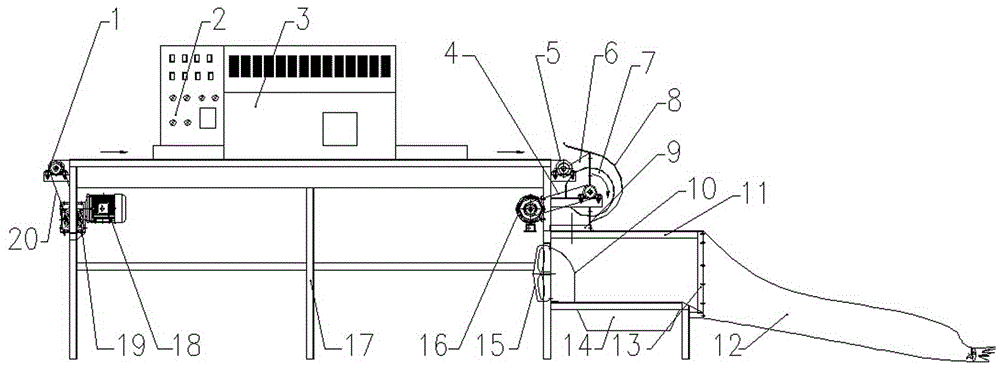

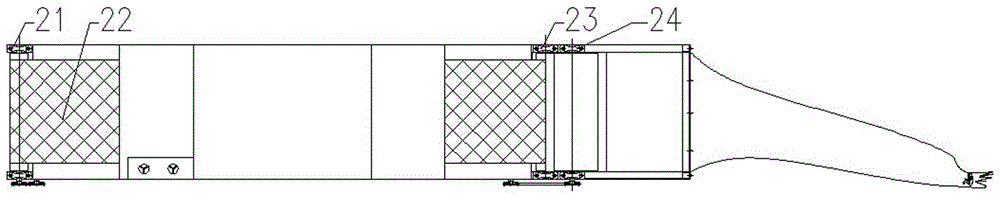

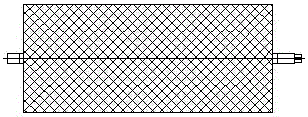

[0018] Example: see Figure 1-3 .

[0019] A kind of Stevia defoliation device, it comprises frame 17, dried leaf collecting bag 12, the platform that is arranged on the frame 17 and conveying device, the drying device that is arranged on the platform and control cabinet 2, is arranged on frame 17- The branch and leaf separation device and branch and leaf sorting device on the side, the transmission belt 22 of the transmission device is arranged horizontally above the middle part of the platform, the transmission belt 22 passes through the drying device, and docks with the entrance of the branch and leaf separation device at the outgoing end, and the branch and leaf separation device The outlet of the branch and leaf sorting device is connected to the inlet of the branch and leaf sorting device, and the leaf outlet of the branch and leaf sorting device is connected to the dry leaf collection bag 12; the control system of the transmission device, the control system of the dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com