Device for assembling cams on a camshaft pipe

A camshaft and cam technology, applied in the direction of cams, valve devices, components with teeth, etc., to optimize the installation space, achieve rationalization, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

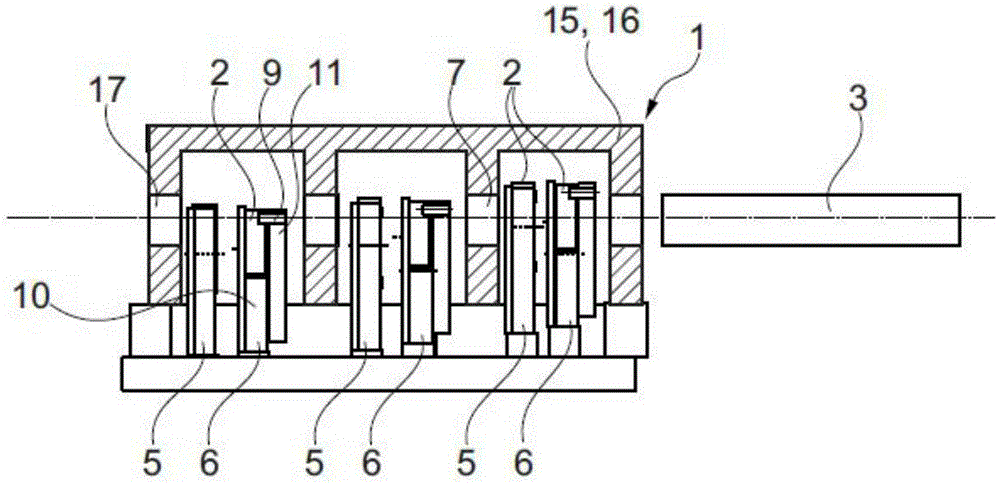

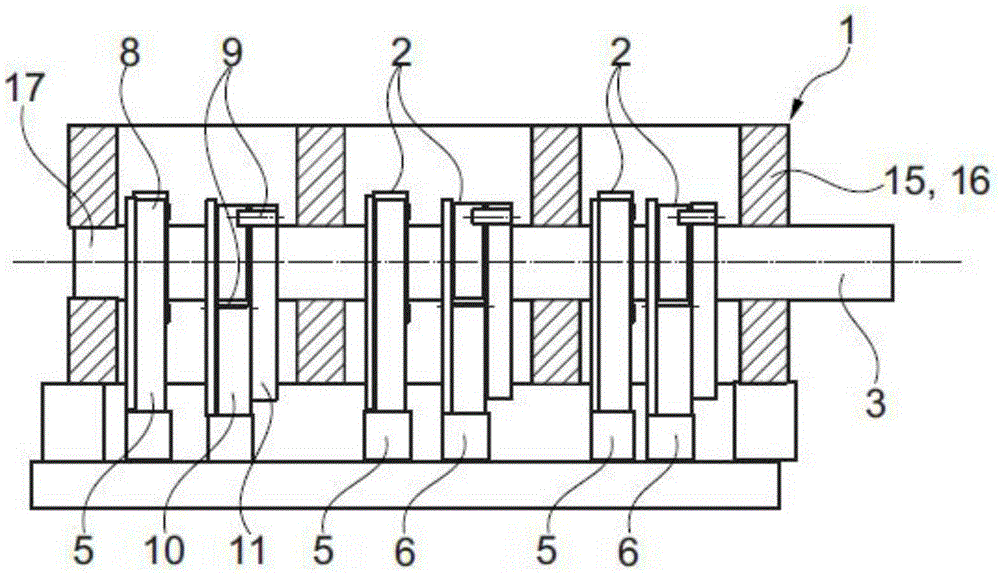

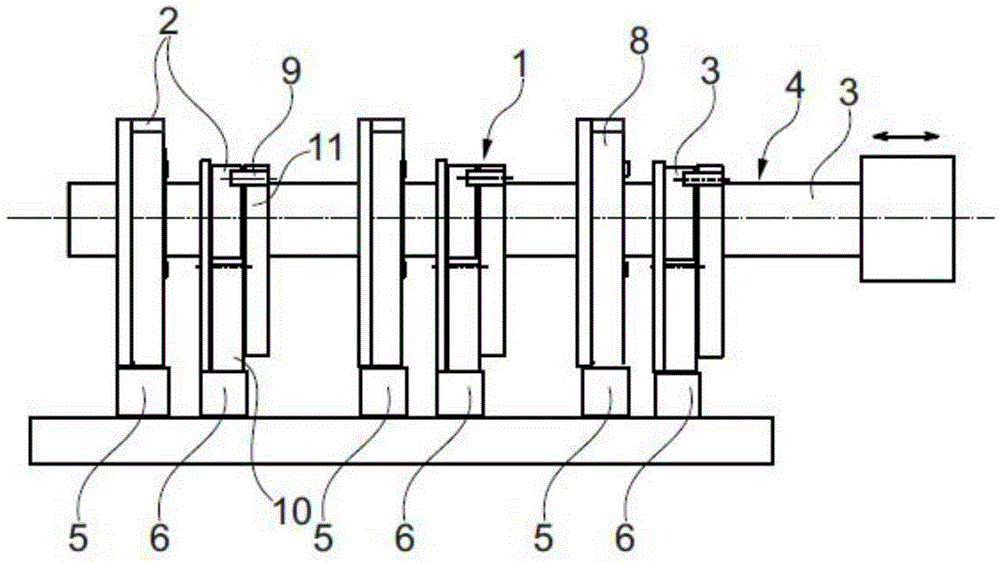

[0044] according to Figures 1 to 3 According to the device 1 of the present invention, the camshaft tube 3 for assembling the cam 2 to the camshaft 4 includes at least one first clamp 5 and a second clamp 6 for clamping and holding the cam 2 during the assembly process.

[0045] In this case, each Figures 1 to 3 All the devices 1 include three first clamps 5 and three second clamps 6 .

[0046] In this case, all fixtures 5, 6 according to the above Figures 1 to 3 Can be fitted to cam 2 from the same direction and moved in the same direction to align with camshaft tube 3.

[0047] In the case shown, the individual clamps 5 , 6 can be adjusted vertically in the manner described so that the cam 2 fixed to the clamps 5 , 6 faces the cam hole 7 aligned with the camshaft tube 3 .

[0048] According to the invention, the second clamp 6 can now hold the cam 2 rotated by 90° relative to the cam 2 held by the first clamp 5 .

[0049] Thus, not only is a particularly space-optimiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com