Manufacturing method for ultrathin seamless metal pipe utilizing floating plug

一种无缝金属管、超薄壁的技术,应用在金属拉拔的成型工具、金属拉丝、制造工具等方向,能够解决成本升高、增加拉拔次数等问题,达到效率实现、扩大可制造范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

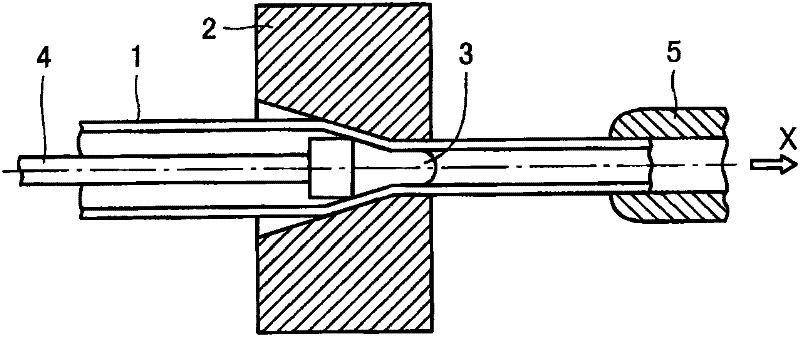

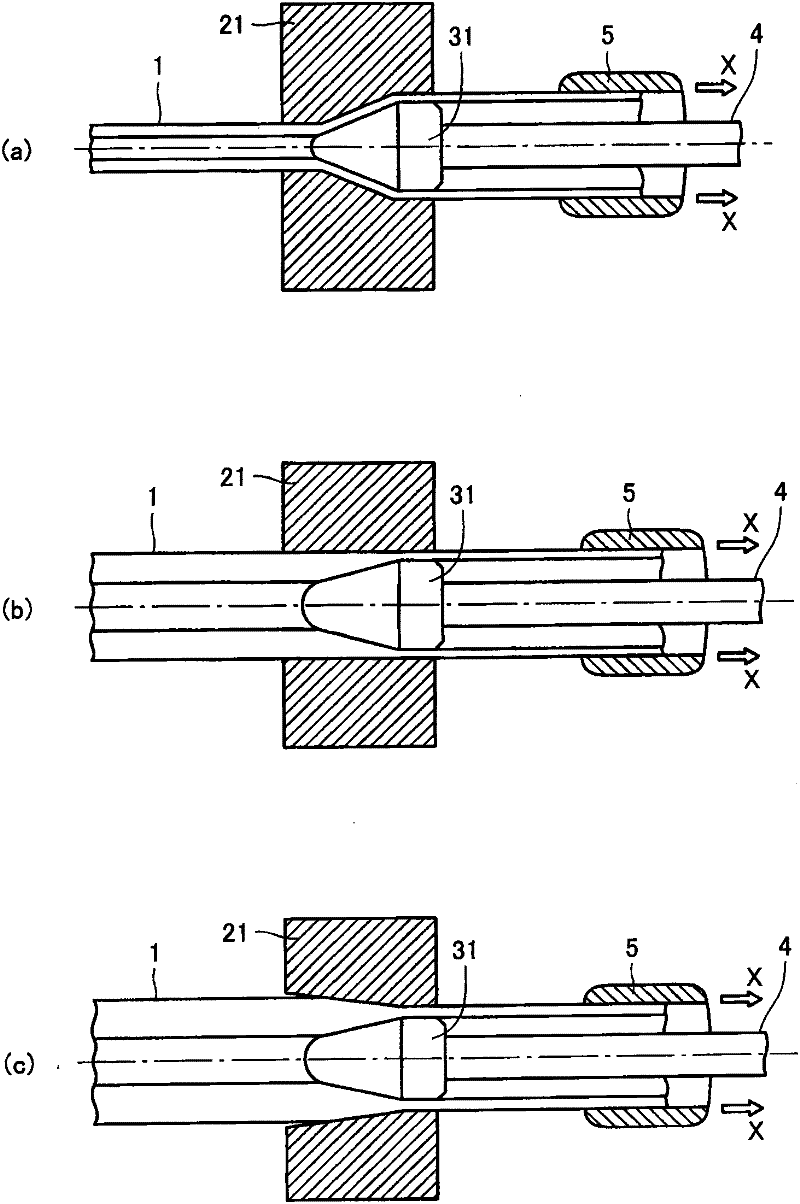

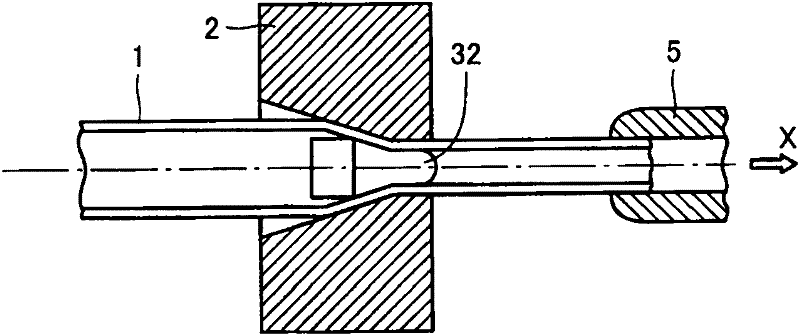

[0055] In order to confirm the effect of the method of manufacturing the ultra-thin seamless metal pipe obtained by the diameter-expanding drawing method using the floating plug of the present invention, the following tests were conducted and the results were evaluated. The test is using the above Figure 4 The method shown in (a) is carried out, but for the Figure 4 (b) and (c) of the method, and the Figure 4 The action and effect of the method of (a) are almost unchanged, therefore, in this embodiment, the Figure 4 Experimental results of the method of (a).

[0056] The 18%Cr-8%Ni stainless steel tube with an outer diameter of 48.6mm, an inner diameter of 41.6mm, and a wall thickness of 3.5mm manufactured by the Mannesmann mandrel rolling process was used as the tube blank for the test. The die and the floating plug formed the tube blank for the test with an outer diameter of 53.8mm, an inner diameter of 50.8mm, and a wall thickness of 1.5mm while expanding the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com