A liquid crystal display film sticking device

A technology of liquid crystal display and film sticking device, applied in the field of display screen, can solve the problems of poor alignment effect and low efficiency, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

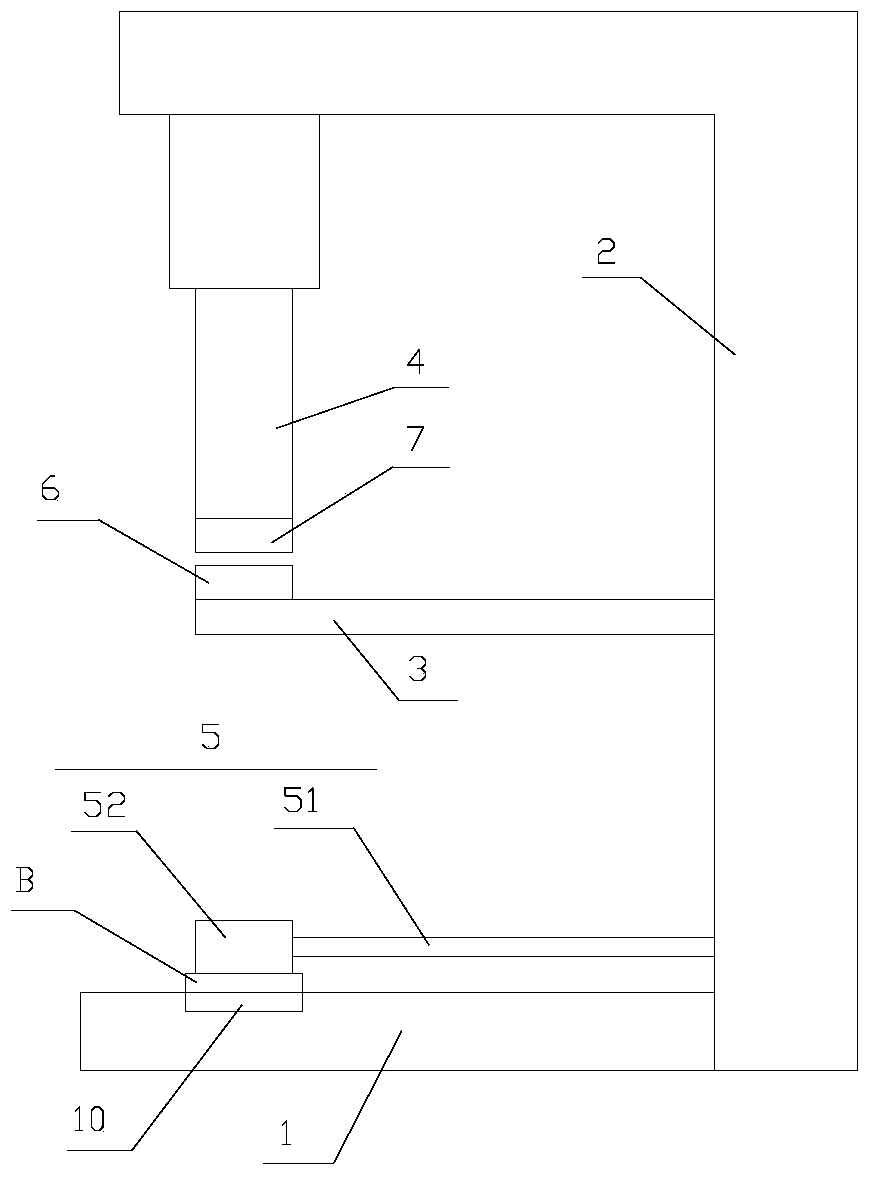

[0021] refer to figure 1 , a liquid crystal display film sticking device proposed by the present invention includes a base 1 , a support base 2 , a film feeding mechanism 3 , a film sticking mechanism 4 and a film pressing mechanism 5 .

[0022] The base 1 is connected to the support base 2, and the base 1 is provided with a limiting groove 10 matching the shape of the liquid crystal display. The film feeding mechanism 3 is horizontally movable and installed on the support base 2, and its end away from the support base 2 is provided with a first clamping member 6, and the first clamping member 6 has a first position state and a second position state during movement , and the first clip 6 can acquire the screen sticker in the first position state. In this embodiment, the film feeding mechanism 3 is hinged to the support base 2 and can rotate in a horizontal plane. In this embodiment, the base 1 and the support base 2 are detachably connected so as to replace the base or the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com