Two-station bearing assembly machine

An assembly machine and two-station technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low assembly accuracy, reduced work efficiency, large errors, etc., and achieve quality assurance, compact structure, and space occupation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

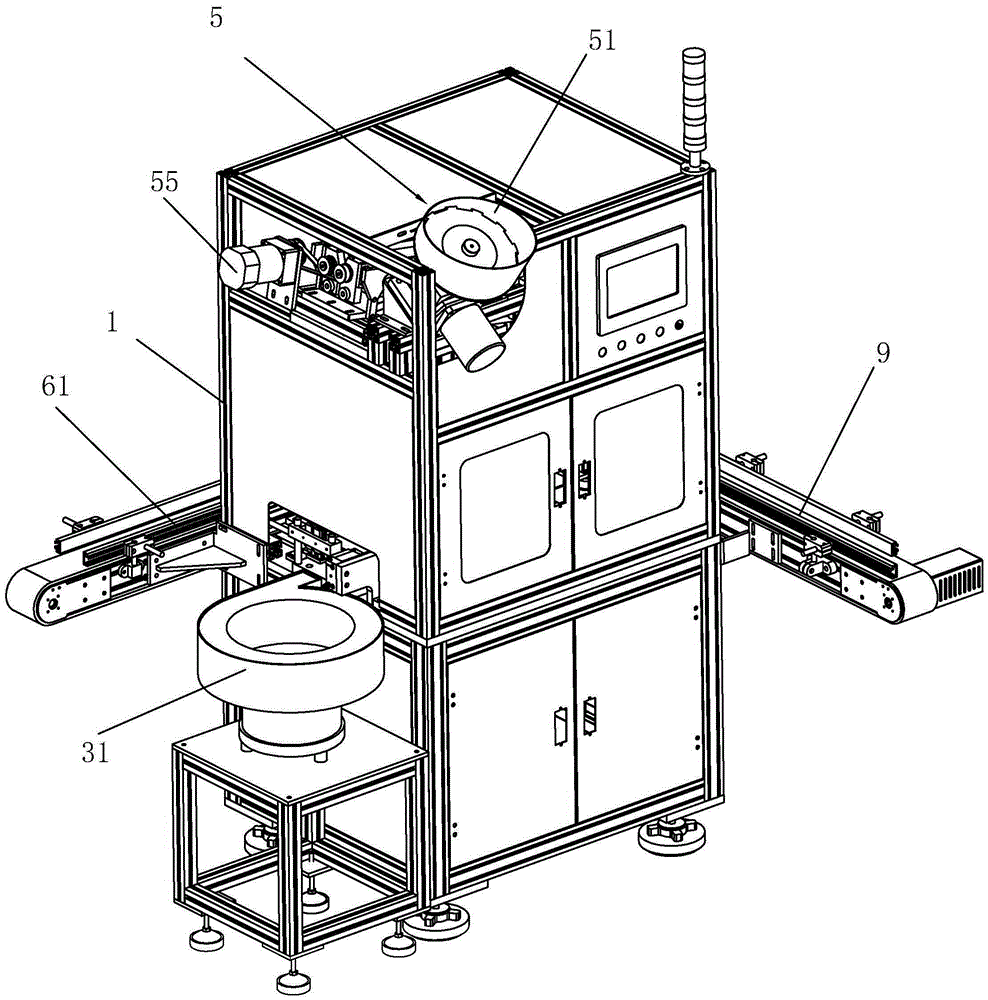

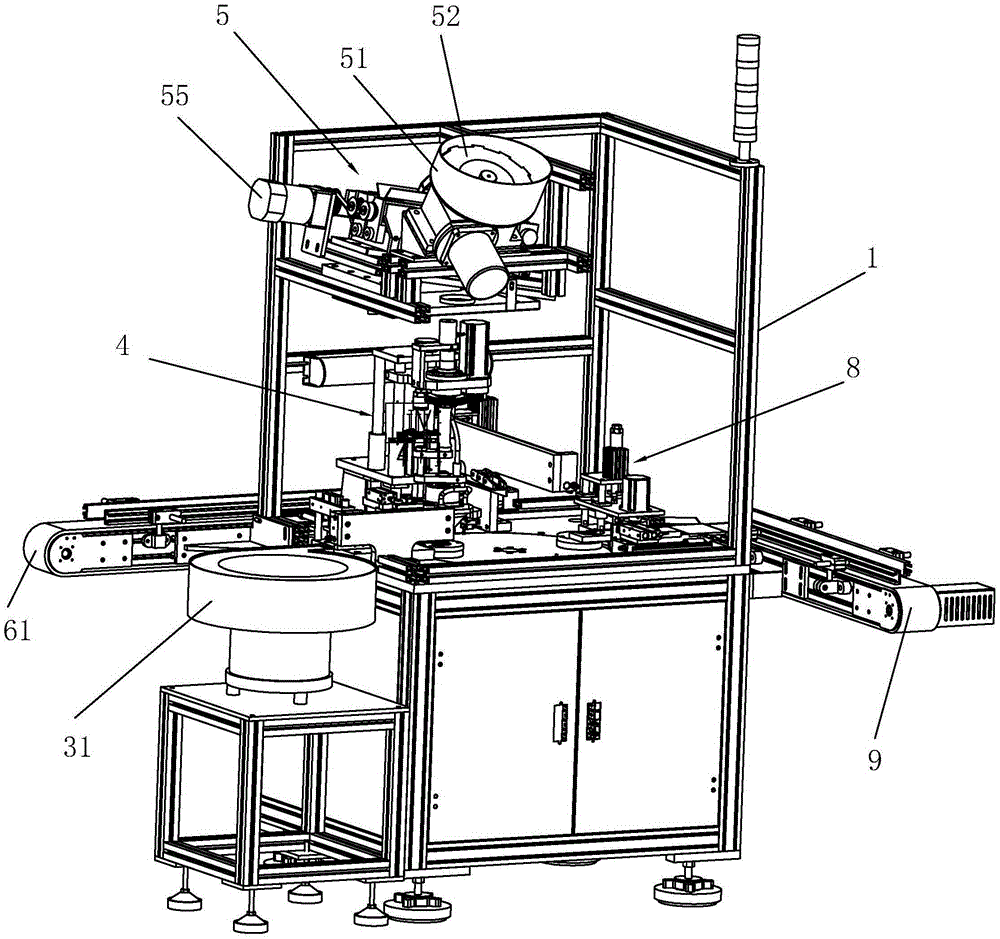

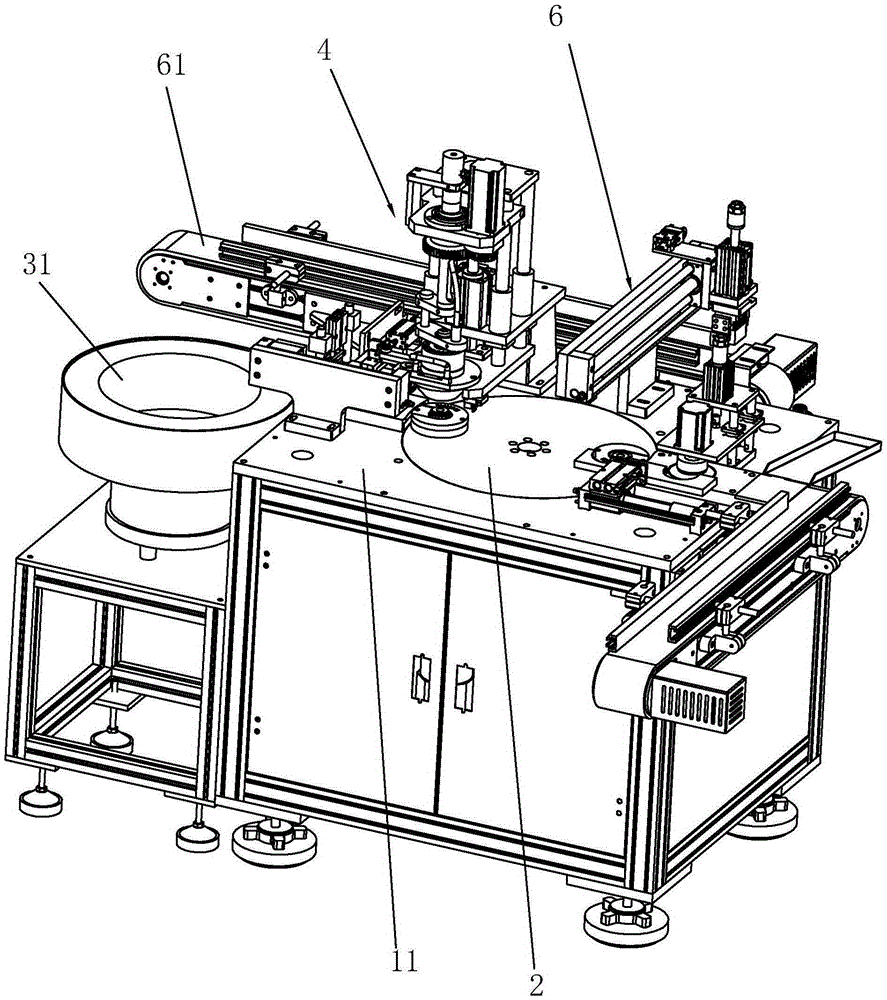

[0039] A two-station bearing assembly machine, comprising a frame 1, on which a workbench 11 is arranged, and on the workbench 11, a first installation station for installing tapered rollers on a cage and an inner ring are installed The second installation station is equipped with a turntable 2 rotating on the workbench 11, and two bearing toolings for installing bearings are arranged on the turntable 2. In order to control the rotation of the turntable 2 conveniently, the bearing tooling takes the center of the turntable 2 as a symmetrical point It is symmetrically arranged on the turntable 2. When working, the turntable 2 rotates 180° at a time to realize the switching between the first installation station and the second installation station of the bearing tooling. The bearing tooling includes a vertical sliding guide set on the turntable 2 Column 21, guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com