Rotary process three-dimensional knitting platform capable of increasing number of carried yarns and knitting method thereof

A three-dimensional weaving and rotating technology, applied in the direction of knitting, textiles and papermaking, can solve the problems of equipment manufacturing cost, occupied space cost and maintenance cost, and achieve the change of size and shape, the realization of yarn, the realization of increase or decrease effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

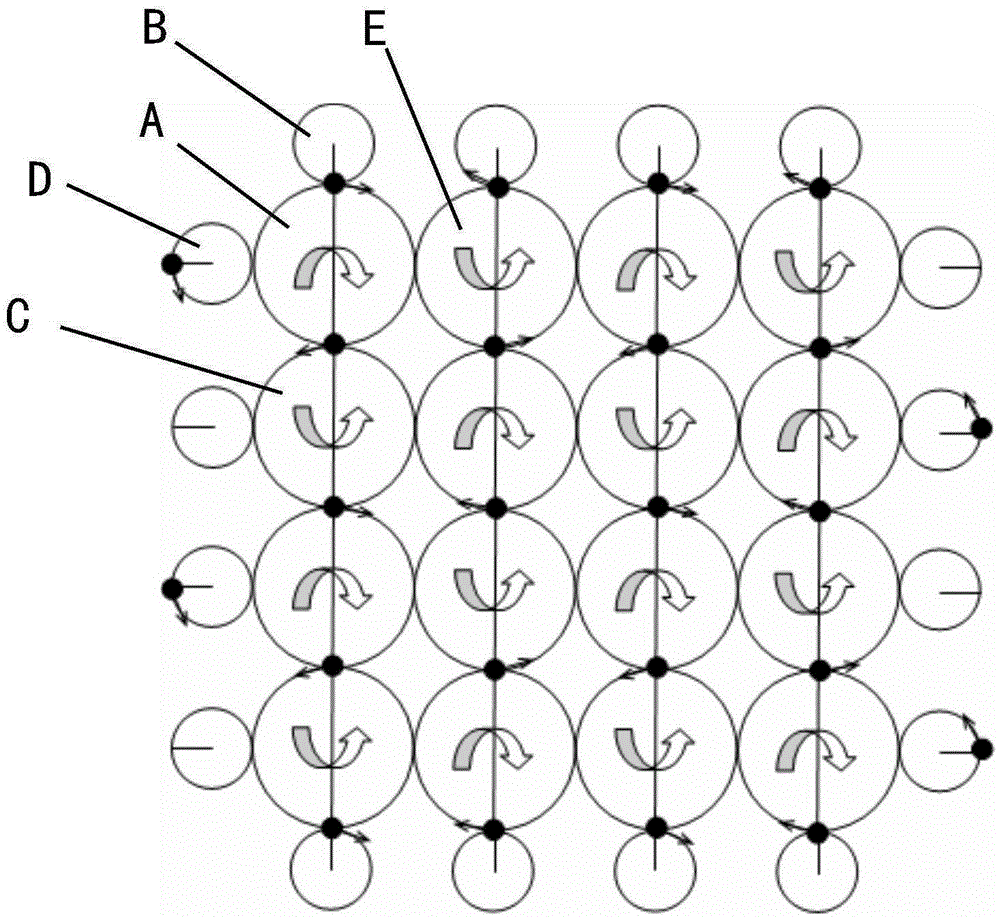

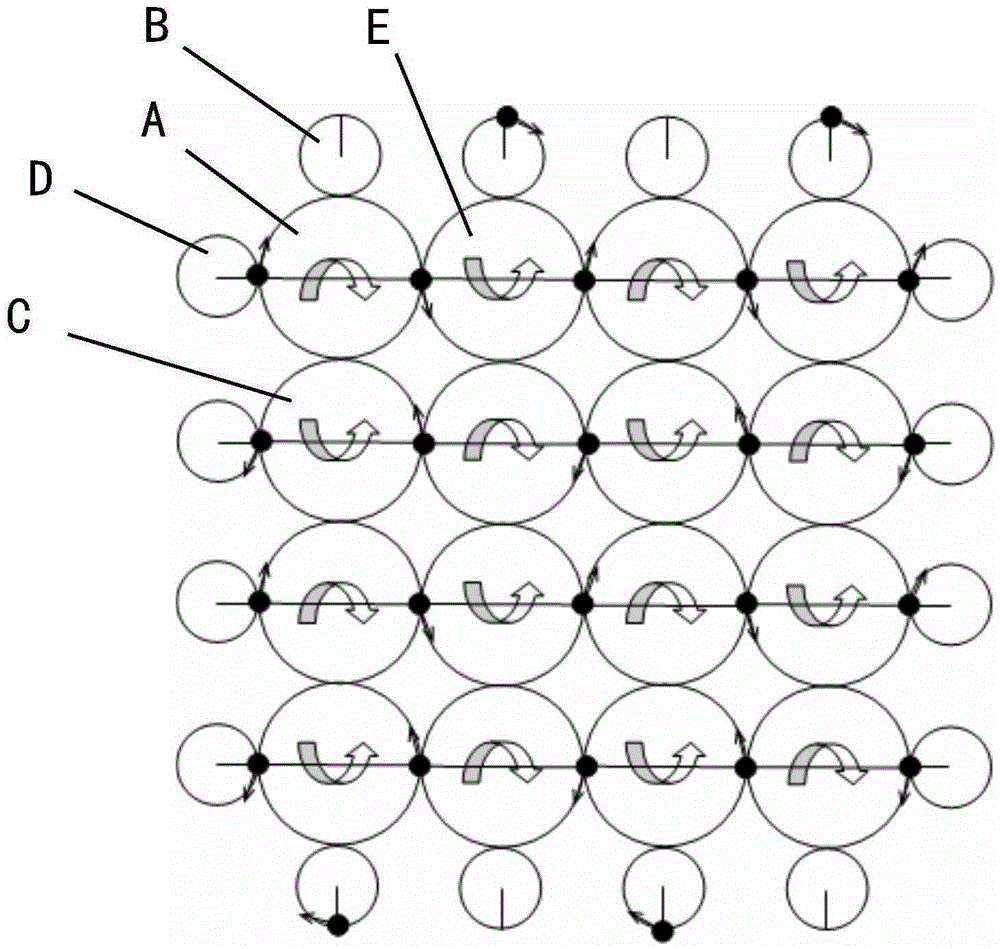

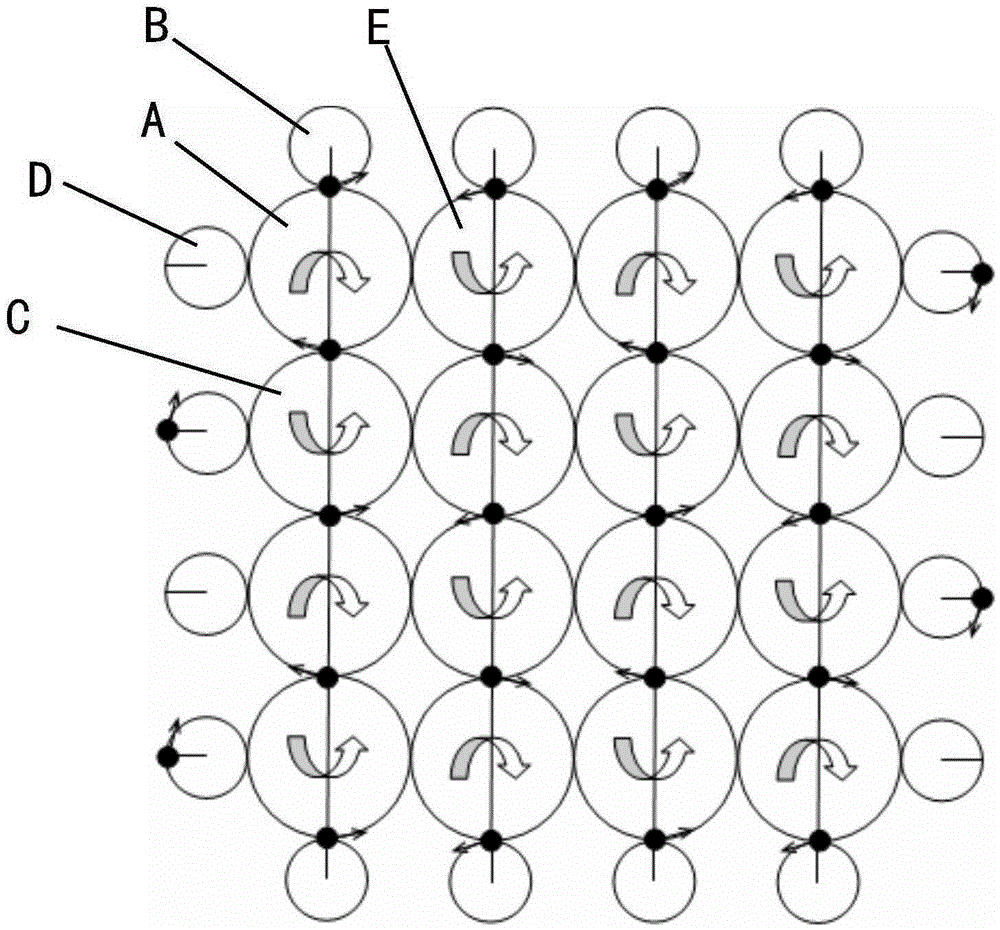

[0028] First introduce the structure and movement of the traditional (that is, one belt one model) three-dimensional weaving platform of the rotation method, such as Figure 1-Figure 5 As shown, it is a schematic diagram of a complete motion cycle. The three-dimensional weaving platform of the rotary method is a rectangular weaving platform, including four rows and four columns, a total of 16 internal yarn disks and 4×4=16 external yarn disks. The yarn discs all rotate synchronously and the rotation direction of any adjacent inner yarn discs is opposite, and the rotation direction of each outer yarn disc is opposite to that of the adjacent inner yarn disc. The diameter of each outer yarn disc is the diameter of the inner yarn disc. half, and the angular velocity is twice that of the inner yarn-carrying disc, each inner yarn-carrying disc is provided with two gaps, and each outer yarn-carrying disc is provided with a gap, which is used for handover and driving the yarn carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com