A kind of flavor farmhouse sauce and its processing method

A processing method, the technology of farmhouse sauce, applied in microbial technology in the field of farmhouse sauce fermentation, can solve the problems of low protein utilization rate, low amino acid composition, low automation level, etc., to shorten the fermentation cycle, reduce the total acid content, and improve the decomposition rate and the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

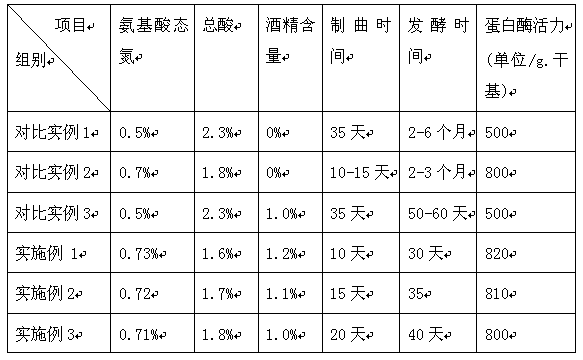

Examples

Embodiment 1

[0016] 1) Cleaning and soaking: Add 3 times the amount of pure water to the cleaned soybeans for soaking. The soaking time is 16 hours in spring and autumn and 12 hours in summer. Soak in water, 5 hours in spring and autumn, 3 hours in summer;

[0017] 2) Cooking: Pump the soybeans and millet soaked in step 1) into the rotary cooking tank according to the weight ratio of 8:3 for high-pressure steaming. The cooking pressure is 0.18MPa for 5 minutes, so that the protein is moderately denatured and the moisture content of the clinker is controlled at 60%. about;

[0018] 3) Block making: the steamed soybeans and millet in step 2) enter the sauce block forming machine through the feeding auger for crushing and forming, and make sauce blocks with uniform density;

[0019] 4) Drying: Send the sauce cubes prepared in step 3) into the pre-sterilized solar drying shed through the sauce cube conveyor, and carry out ventilation and drying. Turn over the sauce cubes once a day to ensure ...

Embodiment 2

[0025] 1) Cleaning and soaking: Add 2.5 times the amount of pure water to the cleaned soybeans for soaking. The soaking time is 14 hours in spring and autumn and 10 hours in summer. Soak in water, 4 hours in spring and autumn, 3 hours in summer;

[0026] 2) Cooking: Pump the soybeans and millet soaked in step 1) into the rotary cooking tank according to the weight ratio of 8:2.5 for high-pressure steaming. The cooking pressure is 0.16MPa for 6 minutes to moderately denature the protein and control the moisture content of the clinker at 60%. about;

[0027] 3) Block making: the steamed soybeans and millet in step 2) enter the sauce block forming machine through the feeding auger for crushing and forming, and make sauce blocks with uniform density;

[0028] 4) Drying: Send the sauce cubes prepared in step 3) into the pre-sterilized solar drying shed through the sauce cube conveyor, and carry out ventilation and drying. Turn over the sauce cubes once a day to ensure that the sau...

Embodiment 3

[0034]1) Cleaning and soaking: Add 2 times the amount of pure water to the cleaned soybeans for soaking. The soaking time is 12 hours in spring and autumn and 8 hours in summer. Soak in water, 3 hours in spring and autumn, 3 hours in summer;

[0035] 2) Cooking: Pump the soybeans and millet soaked in step 1) into the rotary cooking tank according to the weight ratio of 8:2 for high-pressure steaming, the cooking pressure is 0.15MPa, and the cooking time is 7 minutes, so that the protein is moderately denatured, and the clinker moisture is controlled at 60% about;

[0036] 3) Block making: the steamed soybeans and millet in step 2) enter the sauce block forming machine through the feeding auger for crushing and forming, and make sauce blocks with uniform density;

[0037] 4) Drying: Send the sauce cubes prepared in step 3) into the pre-sterilized solar drying shed through the sauce cube conveyor, and carry out ventilation and drying. Turn over the sauce cubes once a day to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com