Plant transplanting device

A plant and stage technology, applied in botany equipment and methods, planting methods, transplanting machinery, etc., can solve the problems of easy contamination of seedbeds, time-consuming transplantation, damage to plant buds, etc., to avoid direct contact with human hands, Improving the effect of rapid and stable transplantation and strength retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

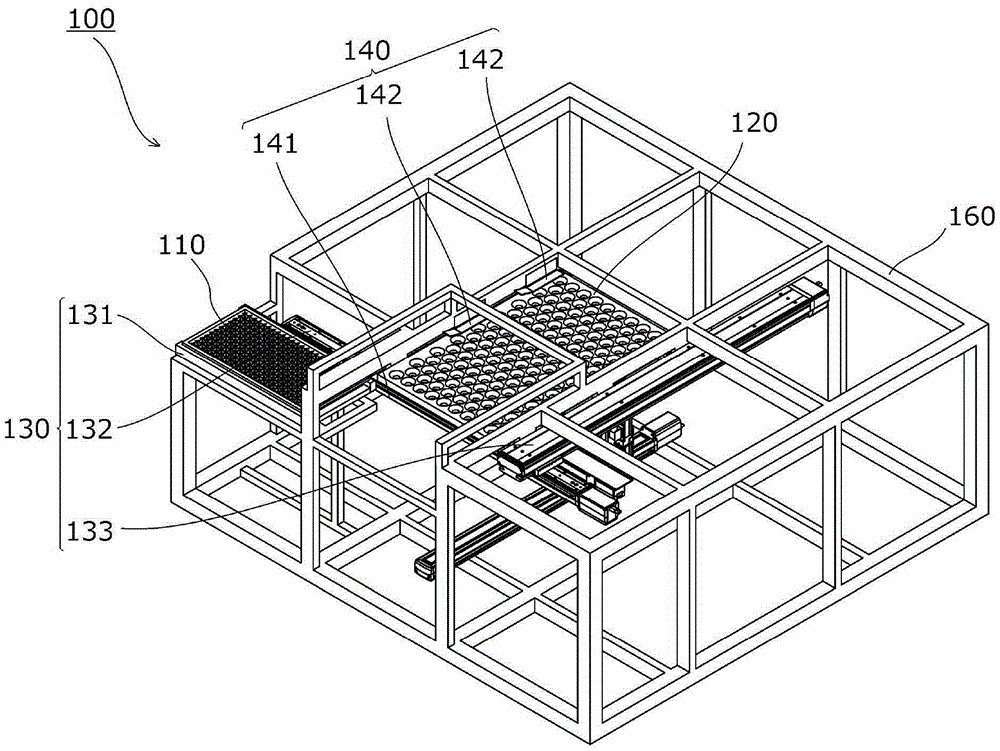

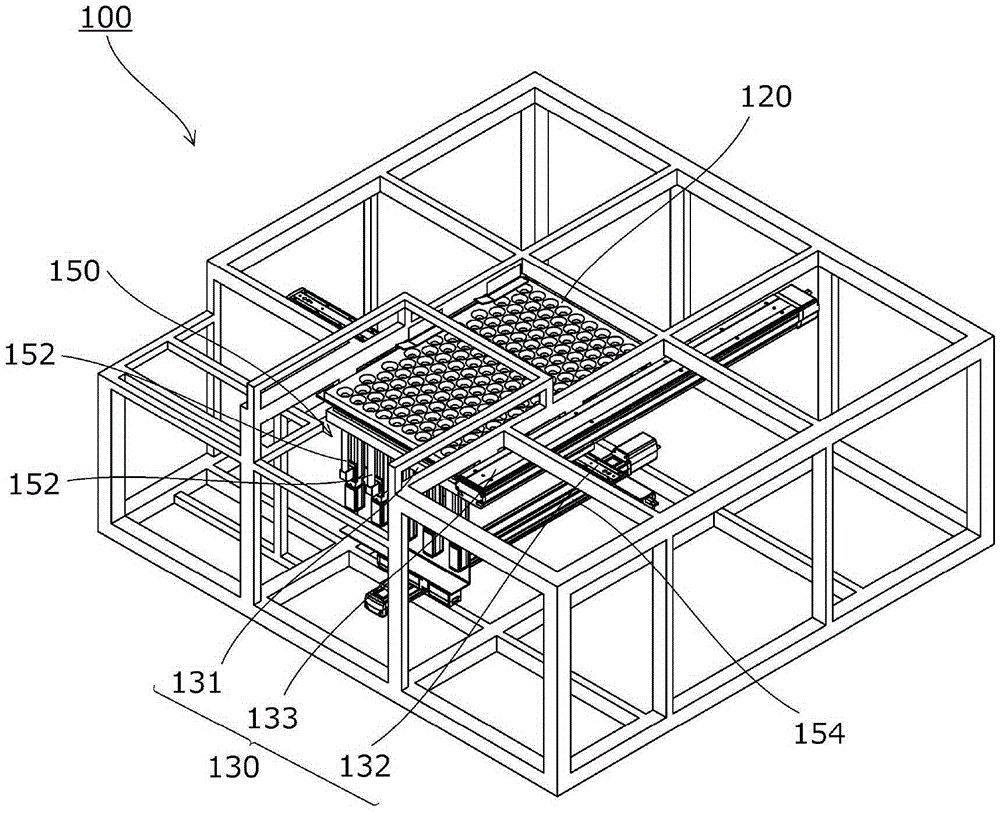

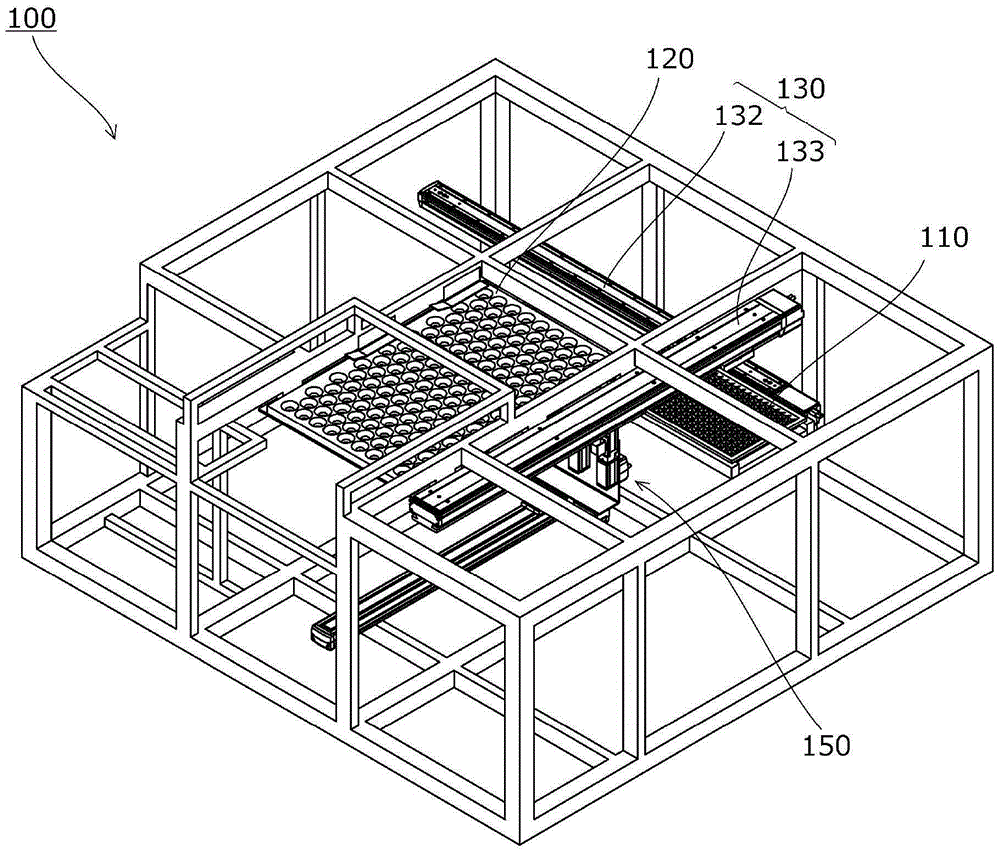

[0061] Hereinafter, the plant transplantation apparatus 100 which is the 1st Embodiment of this invention is demonstrated based on drawing.

[0062] Such as Figure 1~3 As shown, the plant transplanting device 100 has: a grid-like plant holder 110; a tray 120 for cultivation; a seedling raising container (not shown); the holder holds a moving mechanism 130; a tray holding mechanism 140; The operating mechanism (not shown) of 110; And the framework 160 of each part of support holder holding moving mechanism 130, pallet holding mechanism 140, lifting mechanism 150 etc., will be transplanted to the seedbed B that is kept by plant holder 110 with plant. The holder 110 is larger than the cultivation tray 120 .

[0063] The plant holder 110 is formed of a strong material such as metal, such as Figure 6-8 As shown, there are: a plurality of retainer seedbed holding holes 111 for holding the seedbed B penetrating up and down; a thin plate-shaped partition plate 112 that separates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com