Bogie pipeline positioning detection device and positioning and detection methods

A technology of positioning detection device and bogie, which is applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the safety threat of passengers in the service life of the EMU, the measuring equipment does not have the positioning function, and the measurement of the center distance of the pipeline. Difficulty and other problems, to achieve the effect of improving process and testing level, low cost, and rapid positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

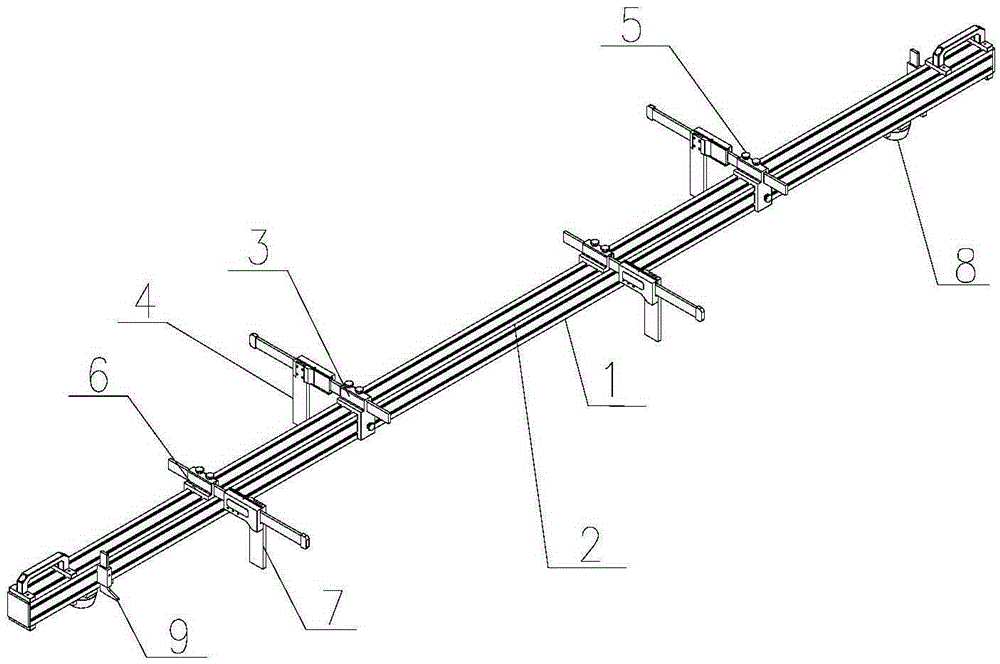

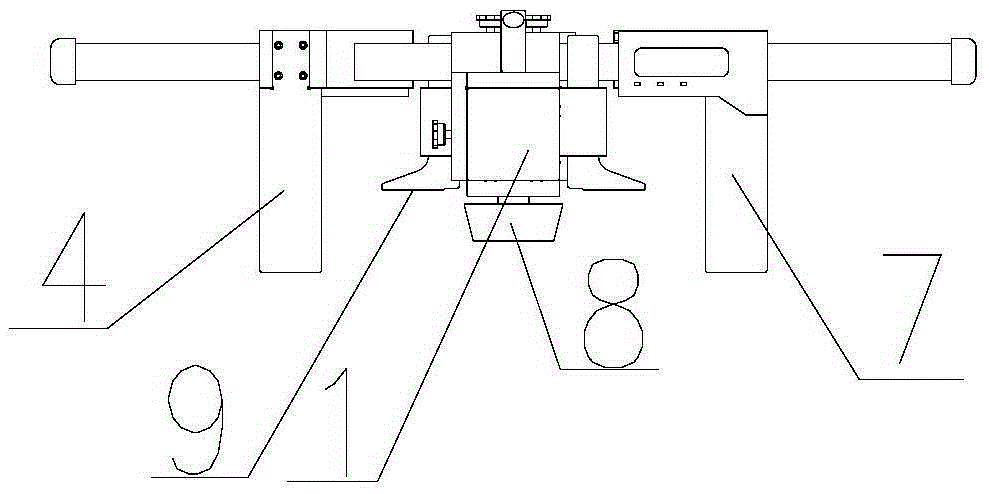

[0040] Such as Figure 1-4 As shown, a bogie pipeline positioning detection device provided in this embodiment includes a base 1, and a scale 2 is provided along the length direction from one end to the other end of the upper surface of the base 1, which can facilitate accurate reading; It is equipped with a positioning mechanism, a measuring mechanism and an assembly mechanism.

[0041] The assembly mechanism is fixedly connected with the base 1, and the assembly mechanism connects the base 1 with the bogie, so that the positioning detection device can be easily loaded and unloaded on the bogie.

[0042] The positioning mechanism is movably connected with the base 1, wherein the connection mode can be any moving mode such as a sliding connection, a rolling connection, etc. that can make the positioning mechanism move along the length direction of the base 1, for example, the positioning mechanism and the base 1 cooperate with a pulley and a guide rail, a slider Cooperate wit...

Embodiment 2

[0052] A positioning method of a bogie pipeline positioning detection device provided in this embodiment includes the following steps:

[0053] a1. Connect the assembly mechanism with the bogie, so that the base 1 is installed on the bogie;

[0054] In this embodiment, specifically, the base 1 is installed on the bogie by inserting the conical mounting block 8 into the hole of the air spring mounting seat of the bogie. According to whether the distance between the vertical positioning block 9 and the air spring mounting seat is equal, Adjust the depth of the tapered mounting block 8 inserted into the hole of the air spring mounting seat of the bogie, so that the base 1 can be adjusted to be flat;

[0055] a2. Adjust the positioning mechanism to the position to be positioned according to the scale 2 on the base 1 and fix it; specifically, adjust the first slider 3 to the position to be positioned, and lock the first slider 3 through the lock nut 5 fixed;

[0056] a3. Install ...

Embodiment 3

[0058] The detection method of a bogie pipeline positioning detection device provided in this embodiment includes the following steps:

[0059] b1. Connect the assembly mechanism with the bogie, so that the base 1 is installed on the bogie;

[0060] In this embodiment, the base 1 is installed on the bogie by inserting the conical mounting block 8 into the hole of the air spring mounting seat of the bogie. The installation block 8 is inserted into the depth of the air spring mounting seat hole of the bogie, so that the base 1 is adjusted to be flat;

[0061] b2. Adjust the measuring mechanism to the position of the pipeline to be measured; specifically, attach the measuring head 7 to both sides of the pipeline to be measured;

[0062] b3. Reading according to the scale 2 at the corresponding position of the measuring mechanism; that is, reading according to the scale 2 at the corresponding position of the second slider 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com