Air deflector structure in main used after flow converging of induced draft fans

A technology of induced draft fan and deflector, which is applied in the field of deflector structure in the main pipe after the confluence of induced draft fans, which can solve the problems of increasing loss along the process, entrained slurry entering, complex flow field, etc., to improve the flow field and reduce the swirl Nest generation, reduce the effect of loss along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

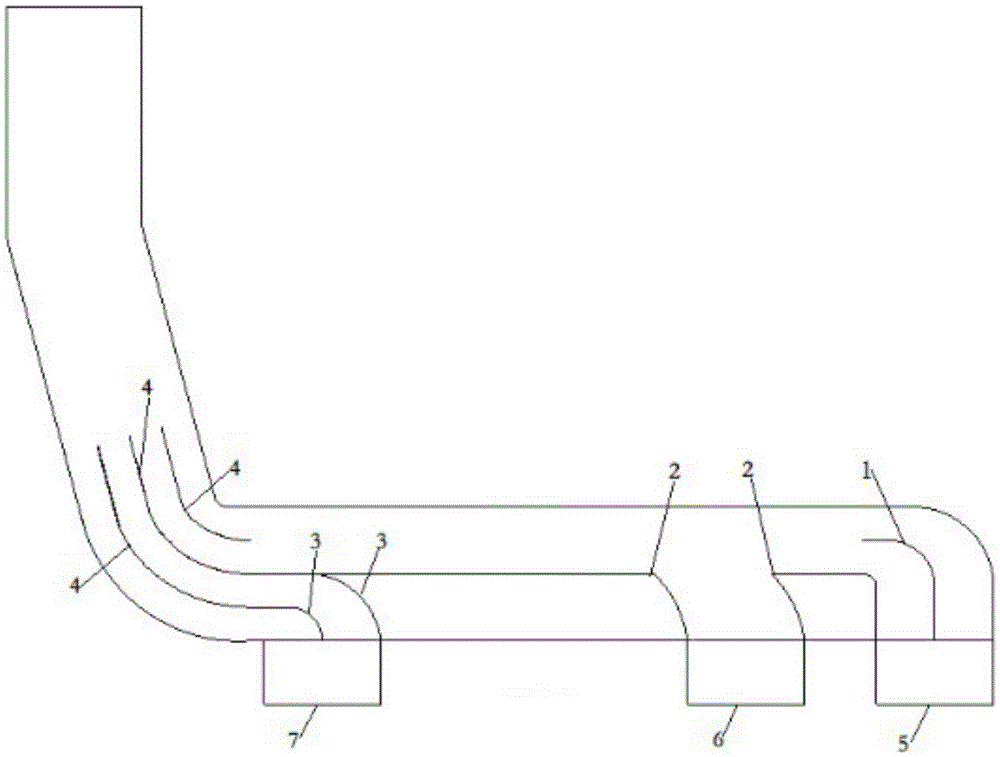

[0016] Such as figure 1 The shown deflector structure device in the main pipe after the confluence of the induced draft fan includes the deflector 1 at the outlet of the first steam-driven induced draft fan, the deflector 3 at the exit of the second steam-driven induced draft fan, the deflector 4 at the corner and Internal baffle 2;

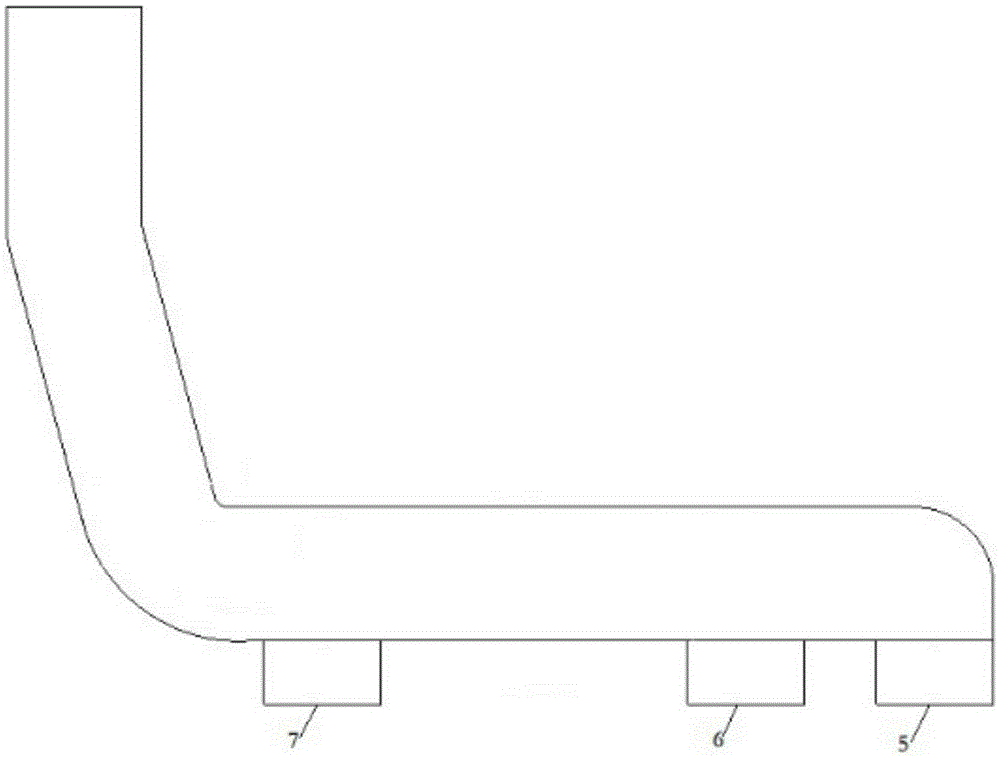

[0017] The outlet 5 of the first steam-driven induced draft fan, the outlet 6 of the electric induced draft fan and the outlet 7 of the second steam-driven induced draft fan are all rectangular air ducts with a cross-section of 7m×6m (7m in the width direction and 6m in the height direction) ); the main pipe air duct is composed of a rectangular channel and an arc-shaped channel, arranged vertically, with a cross-sectional size of 8m×10.2m (8m in the width direction and 10.2m in the height direction);

[0018] The outlet deflector of the first steam-driven induced draft fan is composed of two straight pipe sections and one circular arc section, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com