Linkage type pumping system and engine thereof

A pumping system, linkage technology, applied in the direction of engine components, machine/engine, engine cooling, etc., can solve the problems of low engine efficiency, high manufacturing cost, maintenance, etc., to improve power, improve structure compactness, simplify The effect of the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

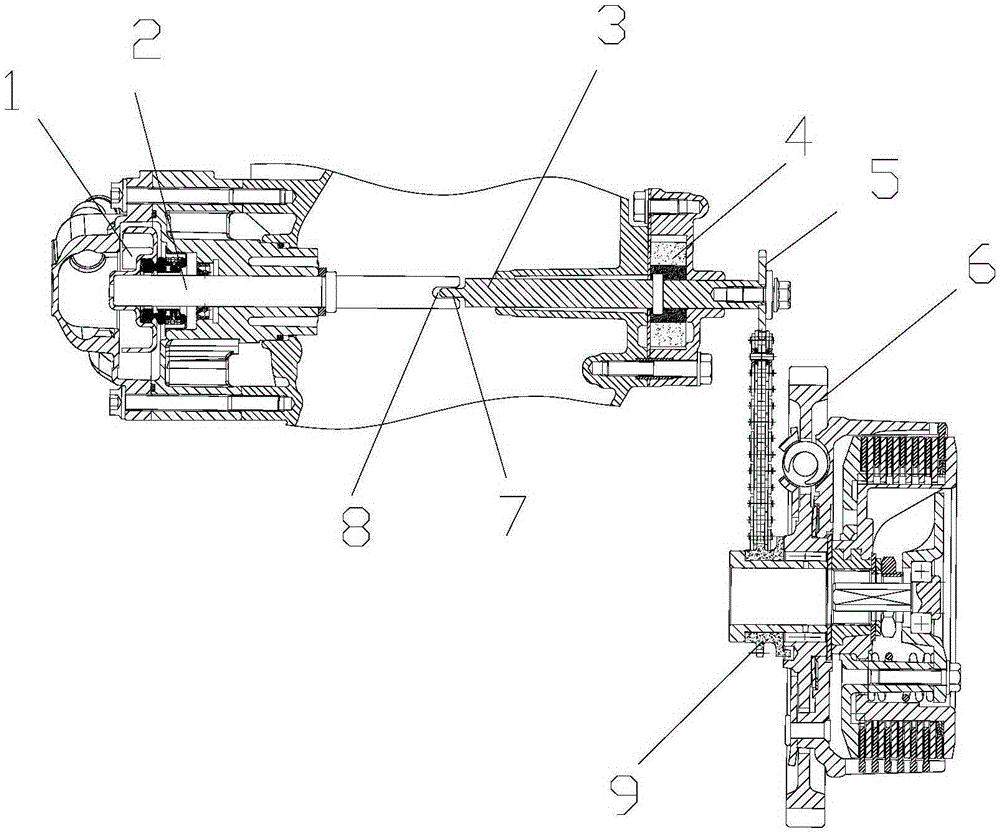

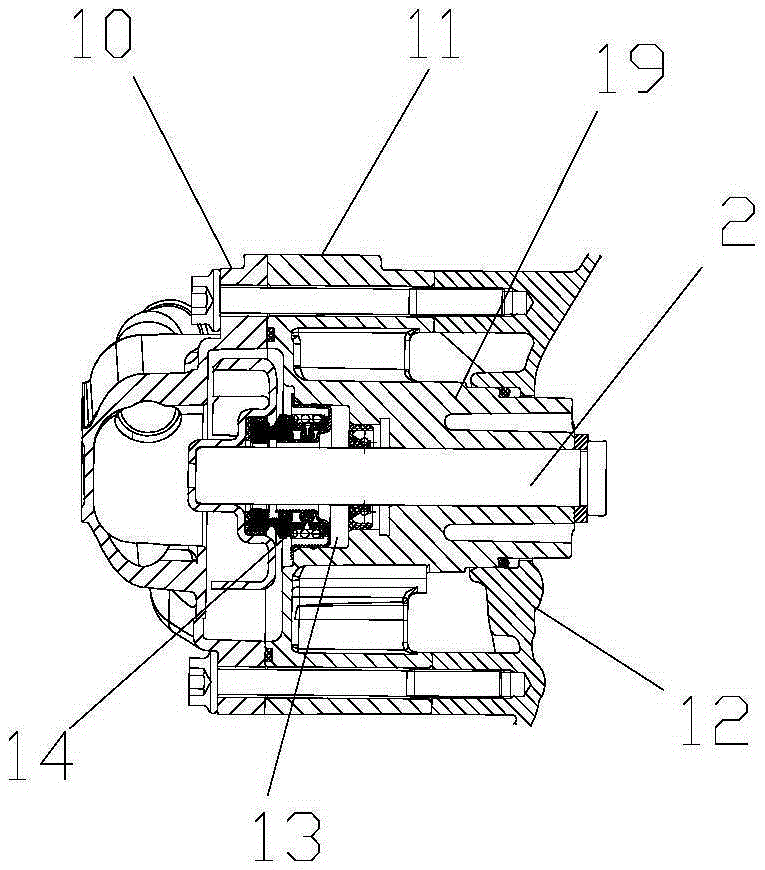

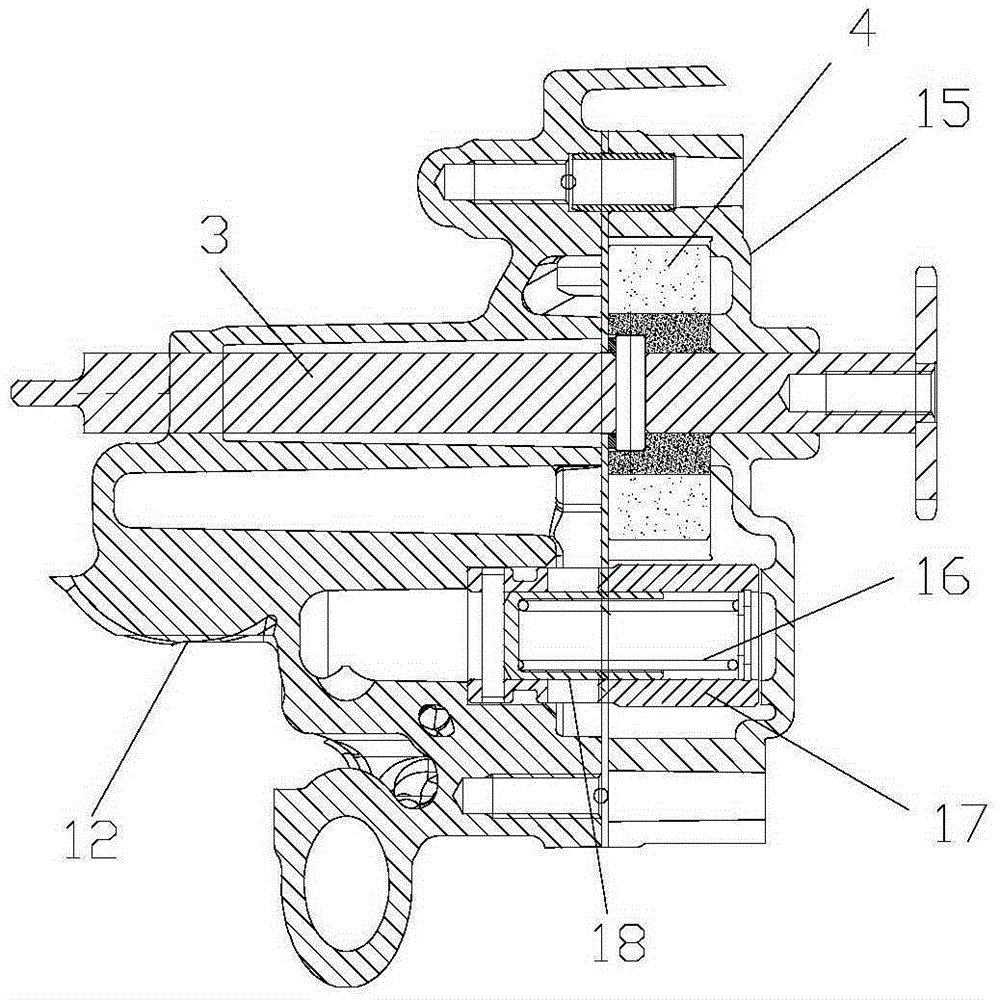

[0020] figure 1 It is a working schematic diagram of the present invention; figure 2 It is a structural schematic diagram of a water pump of the present invention; image 3 It is a schematic diagram of the structure of the oil pump of the present invention. As shown in the figure, the linkage pumping system of this embodiment includes an engine-driven oil pump and a water pump; the oil pump includes an oil pump rotor 4, and the water pump includes The water pump rotor 1 and the oil pump rotor 4 and the water pump rotor 1 have interlocking cooperation; the interlocking mode can be realized by using all existing structures that can transmit power. One transmission shaft, or the oil pump and the water pump each have a rotating shaft, and the transmission connection between the two rotating shafts is realized through all the existing coupling structures; therefore, only one transmission mechanism is needed to drive the oil pump and the water pump to rotate together, thereby impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com