Automotive milling machine, as well as method for discharging milled material

一种自动推进、铣刨机的技术,应用在道路或地面工作单元,卸放铣刨材料领域,能够解决影响自动控制过程等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

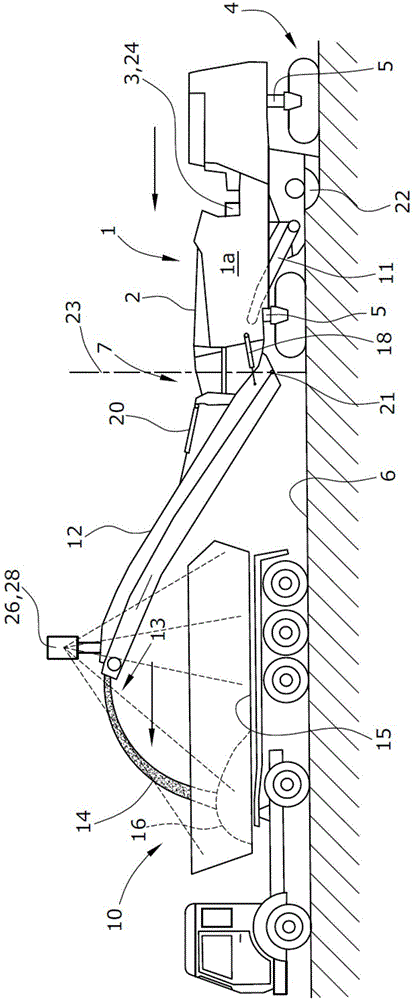

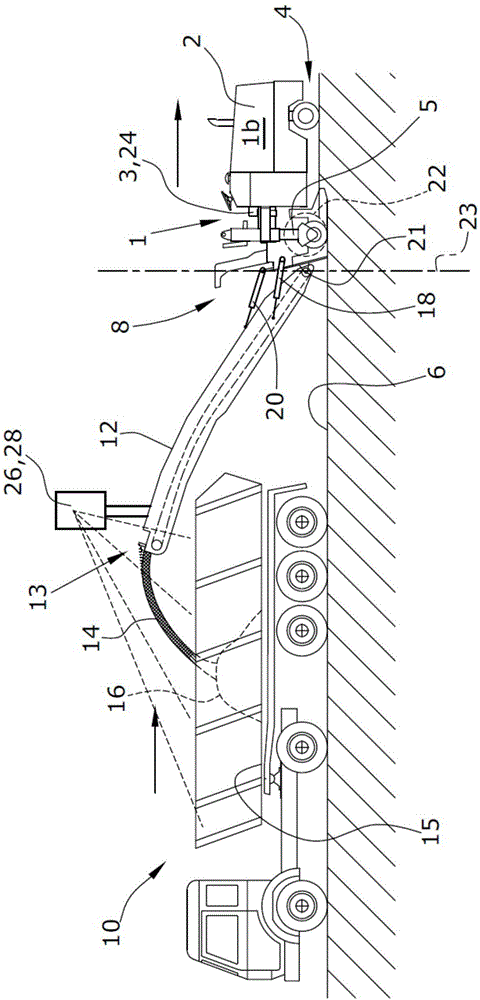

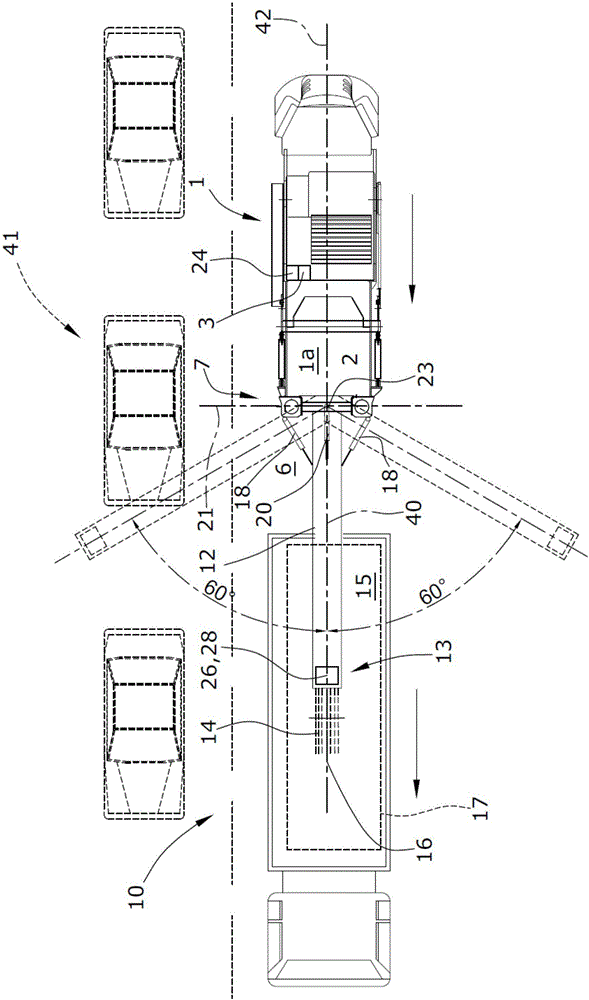

[0037] figure 1 A milling machine used as an example of a front loading road milling machine la is depicted. The milling machine 1 comprises a machine frame 2 supported by a chassis 4, for example comprising tracked ground engaging units or wheels, connected to the Machine frame 2. as available from figure 1 As derived from , the present embodiment specifies four lifting columns 5 that can be used to bring the machine frame 2 into a specified plane extending preferably parallel to the road surface 6 that supports the tracked ground engaging units of the chassis 4 or wheel.

[0038] figure 1 The road milling machine 1 shown in the figure comprises a working drum 22 between the tracked ground engaging units of the chassis 4 in the length direction of the milling machine 1a.

[0039] The milling machines 1a, 1b may comprise tracked ground engaging units or wheels. The working drum is adjustable in height via a lifting column 5 supporting the machine frame 2 or relative to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com