Smart impact-resisting material and preparation method thereof

An impact-resistant and intelligent technology, applied in the field of functional materials, can solve the problems of limited temperature range, limited shock absorption performance, equipment damage, etc., and achieve the effect of easy industrial production and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

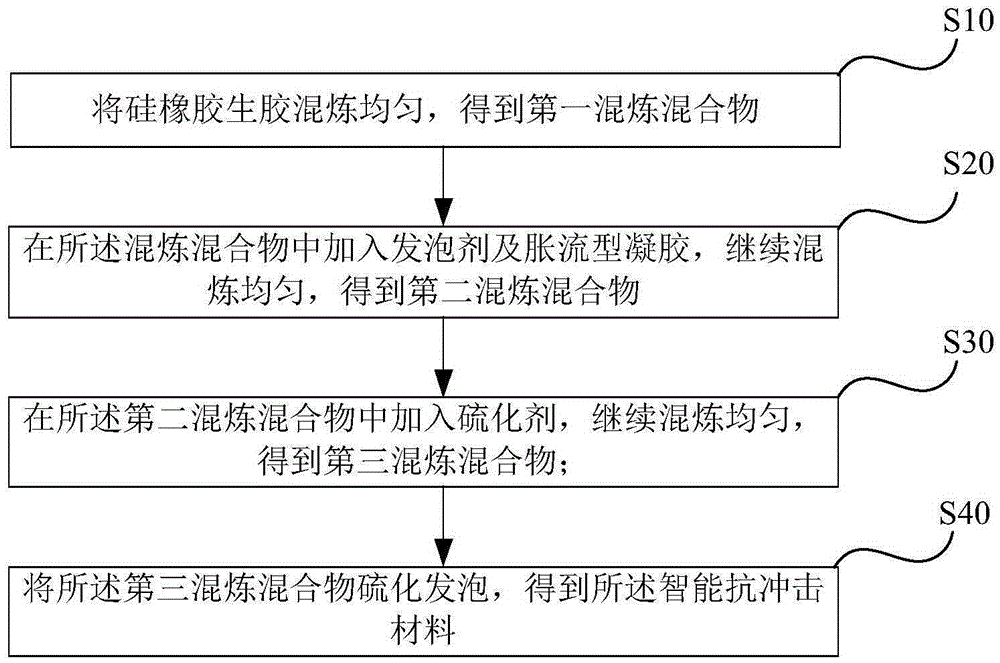

[0029] Such as figure 1 As shown, the preparation method of an intelligent impact-resistant material in one embodiment includes the following steps:

[0030] Step S10: kneading the raw silicone rubber evenly to obtain a first kneading mixture;

[0031] Preferably, the silicone rubber is at least one of dimethyl silicone rubber, methyl vinyl silicone rubber, methylphenyl silicone rubber, fluorosilicone rubber, nitrile silicone rubber, ethyl silicone rubber, and ethylphenylene silicone rubber A sort of.

[0032] Step S20: adding a foaming agent and a dilatant gel to the kneading mixture, and continuing to knead evenly to obtain a second kneading mixture;

[0033] Preferably, the foaming agent is AC foaming agent or OBSH foaming agent.

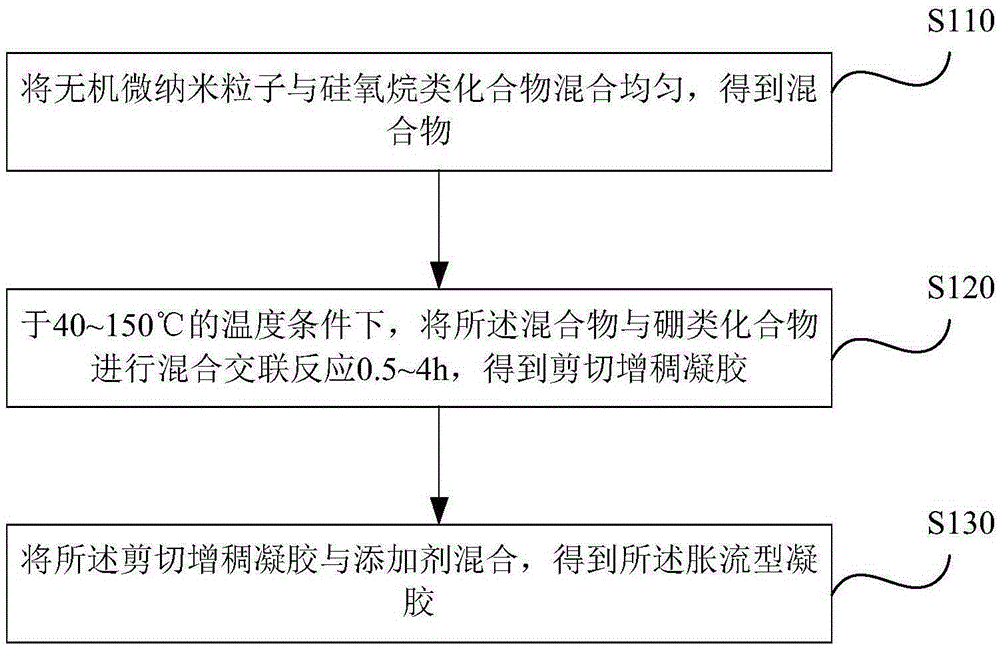

[0034] Preferably, as figure 2 Shown, the dilatant gel is prepared by the following method:

[0035] Step S110: uniformly mixing the inorganic micro-nano particles and the siloxane compound to obtain a mixture;

[0036] Wherein, the inorga...

Embodiment 1

[0055] The preparation process of the intelligent anti-shock material of the present embodiment is as follows:

[0056] Mix dimethyl silicone rubber on an open mixer, add AC foaming agent and dilatant gel together after mixing evenly, continue mixing, add vulcanizing agent DCP after mixing evenly, and then mix for a period of time Film out. After 4 hours, place the rubber on a flat vulcanizing agent for vulcanization at a temperature of 150°C, a pressure of 100 MPa, and a time of 15 minutes to obtain the final product. .

Embodiment 2

[0058] The preparation process of the intelligent anti-shock material of the present embodiment is as follows:

[0059] Mix the methyl vinyl silicone rubber on the open mixer, add the OBSH foaming agent and dilatant gel together after mixing evenly, continue mixing, add the vulcanizing agent BPO after mixing evenly, and then mix for a period of time The film is released in time, and then the rubber is placed in the mold for vulcanization at a temperature of 170°C and a pressure of 600MPa for 10 minutes. Then post-treatment at 200°C for 2 hours to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com