A rice flour dry packing machine

A technology of dry packing machine and rice noodles, which is applied in the field of packaging, can solve the problems of packaging material consumption, inapplicability, and a large number of workers, and achieve the effect of improving efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

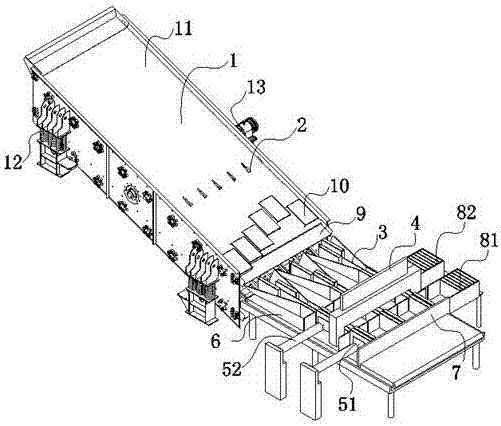

[0030] Embodiment: a kind of rice flour dry packing machine.

[0031] refer to figure 1 Shown, a kind of rice flour dry packing machine comprises:

[0032] Inclined vibrating screen 1, the inclined vibrating screen 1 includes a vibrating inclined plane 11, a plurality of vibrating springs 12 are arranged on both sides below the vibrating inclined plane 11, and a vibrating motor 13 is installed on the lower part of the vibrating inclined plane 11. One side, and drive the shaking inclined plane 11 to vibrate;

[0033] A plurality of guide blocks 2 installed on the shaking slope 11, the guide blocks 2 are evenly arranged along the horizontal straight line of the shaking slope 11;

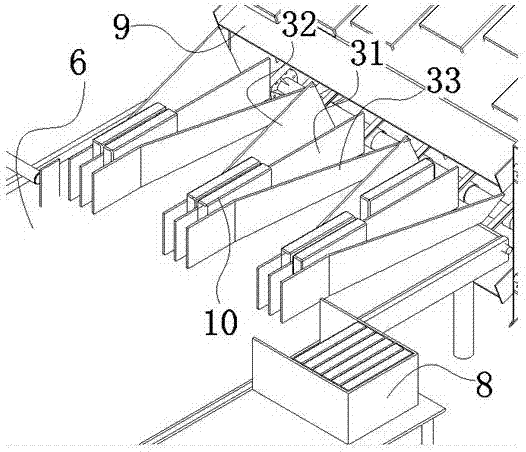

[0034] The conveyor belt 6 arranged below the end of the inclined vibrating screen 1;

[0035] A plurality of overturning mechanisms 3 arranged above the conveyor belt 6, the overturning mechanisms 3 are evenly arranged along the transverse straight line of the shaking inclined surface 11;

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com