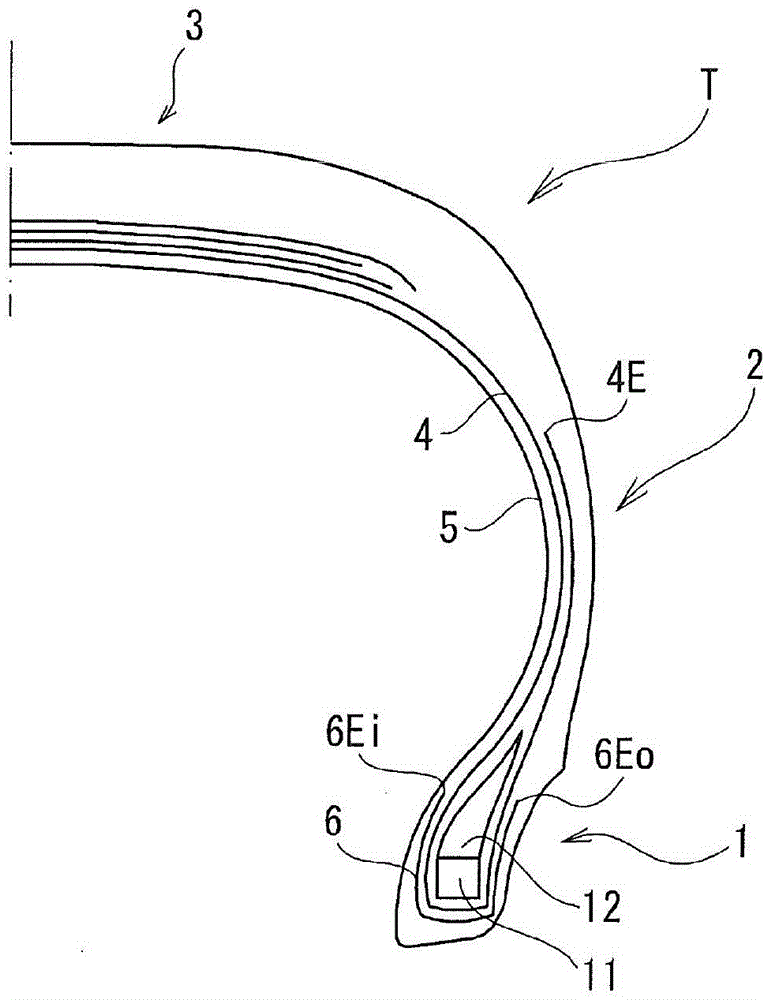

Pneumatic tire

A technology for pneumatic tires and plies, applied in the reinforcement layer, tire parts, transportation and packaging of pneumatic tires, can solve problems such as delamination, improve durability, suppress deformation, and prevent delamination and other failures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

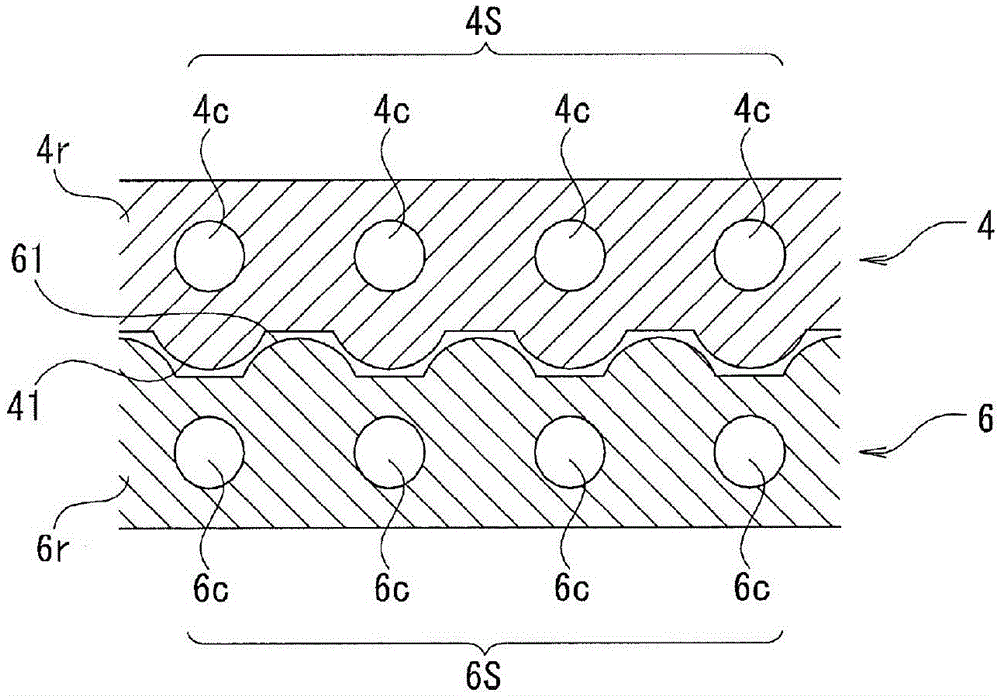

[0053] (1) In the present invention, the second protrusion made of the second topping rubber 6r may be provided on the surface 6A of the chafer 6 adjacent to the carcass ply 4 and above the chafer cord 6c. The bar protrudes 61 . exist Figure 4 A cross-sectional view of the carcass ply 4 and the chafer 6 of the present embodiment is shown in . In the present embodiment, the carcass ply 4 and the chafer 6 are arranged such that the first ridge protrusion 41 and the second ridge protrusion 61 face each other. Thereby, since the distance between the carcass cord 4c and the chafer cord 6c can be appropriately maintained, deformation at the member end can be suppressed, and failures such as delamination can be prevented. However, since the gap between the carcass ply 4 and the chafer 6 becomes large, there is a possibility that air may enter.

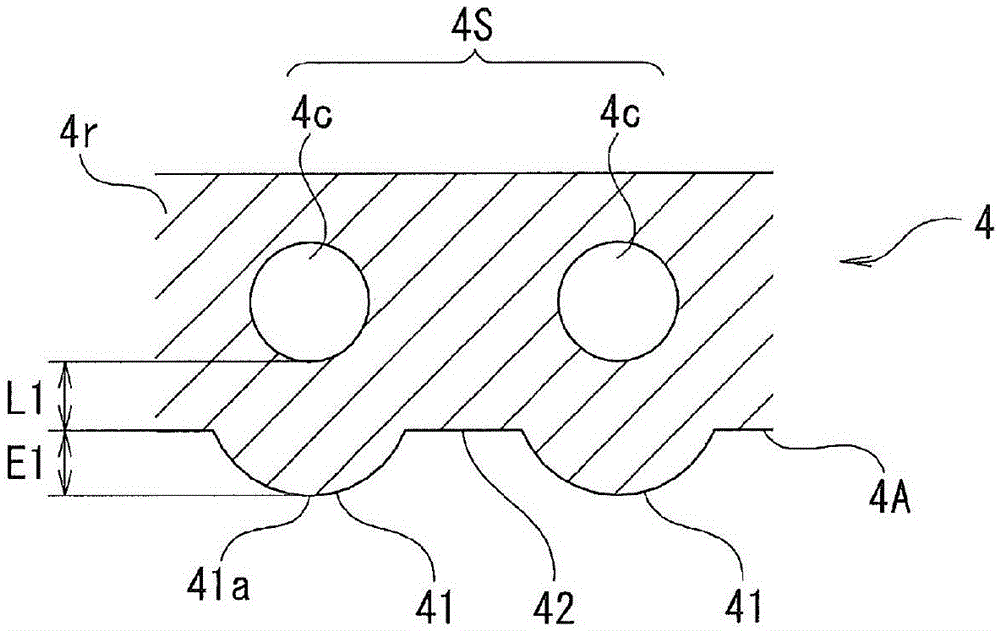

[0054] (2) In addition, if Figure 5 As shown, it is also possible to Figure 4 The illustrated carcass ply 4 and chafer 6 are configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com