Manual adjustment tapered wedge type closed die height adjusting device

A technology of height adjustment and manual adjustment, applied in the direction of presses, manufacturing tools, etc., can solve the problems of inability to achieve accurate mold adjustment of different materials, low precision of mold closing height adjustment, and inconvenient use, etc., to achieve high rigidity and self-locking Good performance, the effect of improving the adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

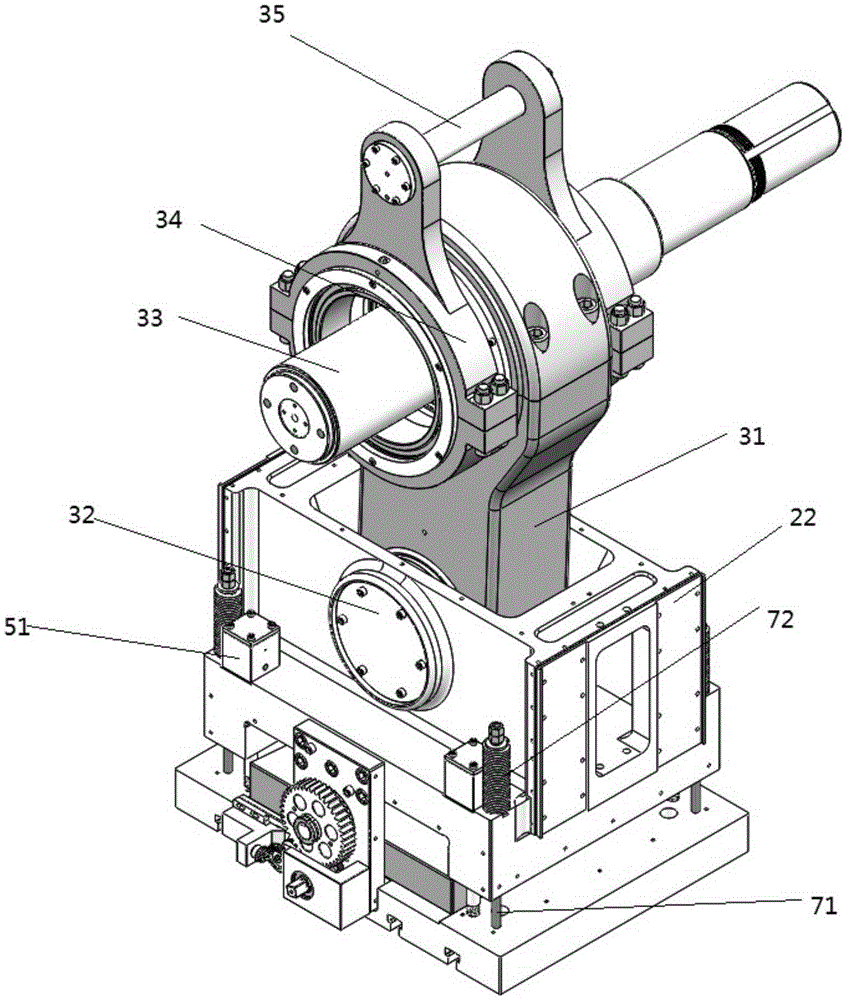

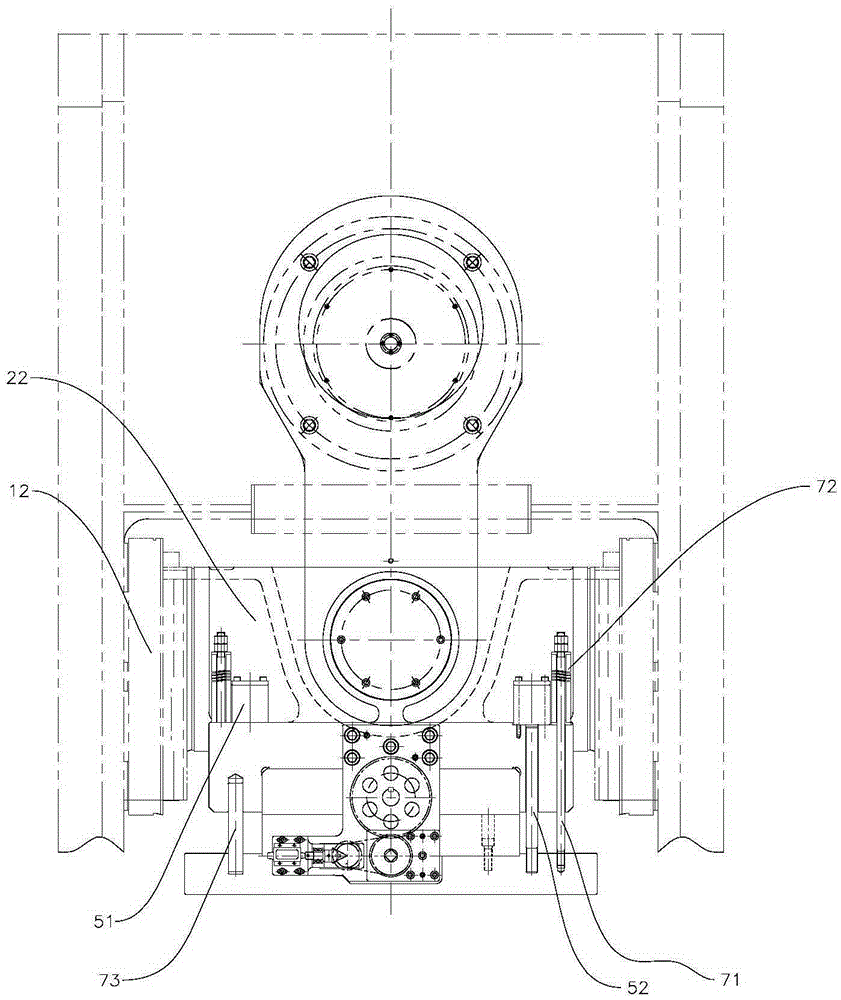

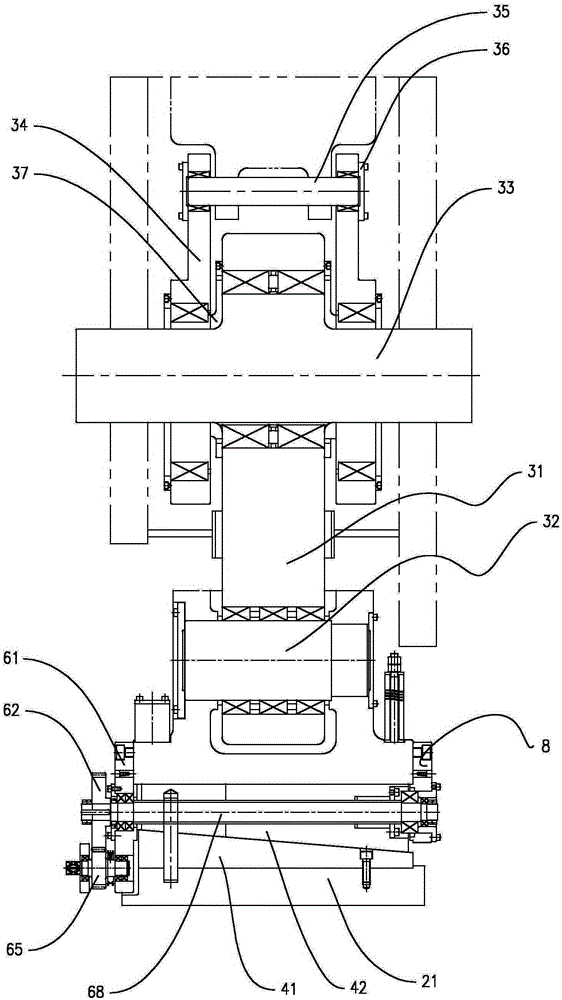

[0020] like Figure 1 to Figure 4 As shown, a manual adjustment wedge block type closed mold height adjustment device of the present invention includes a frame assembly, a slider assembly, a connecting rod assembly, a wedge block assembly, an oil cylinder assembly, a transmission adjustment assembly and an auxiliary guide assembly, and the machine The frame assembly includes a frame and guide rails 12 on both sides of the installation frame; the slider assembly includes a slider bottom plate 21 and a slider body 22, the slider bottom plate 21 is installed on the bottom of the slider body 22, and the slider body 22 passes through the slider pin Connected to the connecting rod assembly; the connecting rod assembly includes a main connecting rod 31, a rotating main shaft 33, a secondary connecting rod 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com