Gripping method of manipulator gripping device

A technology of manipulators and grippers, which is applied in the field of picking and unloading devices, can solve the problems of low manual handling efficiency and high labor costs, and achieve the effects of not being easily deformed, improving gripping quality, force output and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

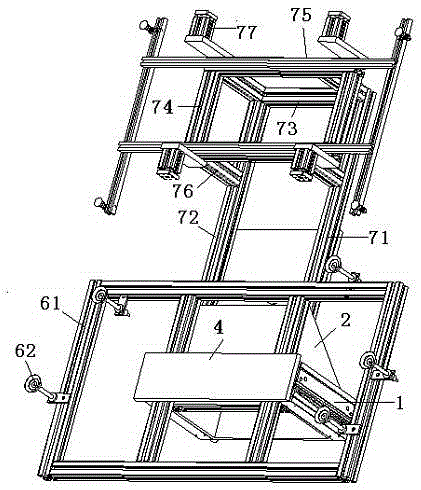

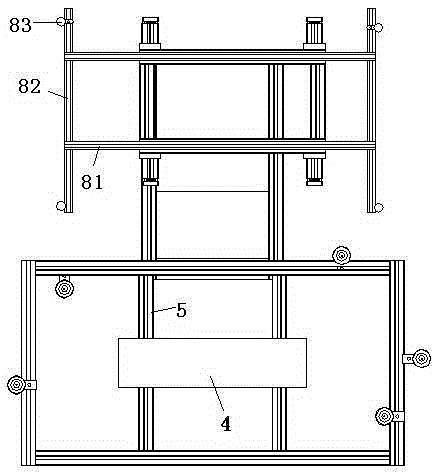

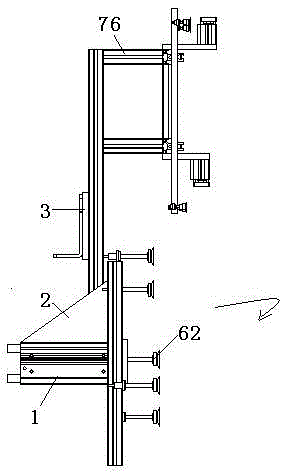

[0033] combine figure 1 , figure 2 and image 3 , the grasping method of a kind of manipulator grasper of the present embodiment, it is characterized in that, its steps are as follows:

[0034] Step 1: Rotate the manipulator gripper in the vertical state by 90° by controlling the connection block 3, and use the suction cup 62 on the first gripper to absorb the sheet metal parts on the workbench;

[0035] Step 2: Rotate the gripper of the manipulator that obtained the sheet metal parts by 90° to reset, and then transfer the gripper of the manipulator to the injection mold of the front-end module, so that the second gripper is aligned with the opening of the mold, so that the limit of the limit device Block 83 rests on the mould;

[0036] Step 3: Adjust the base of the oil cylinder 77 of the second gripper to align with the upper beam and the lower beam of the front-end module after the mold is opened, and start the oil cylinder 77 so that the second gripper is against the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com