Pipe production pressure stabilizing device

A technology of voltage stabilizing device and pipe fittings, which is applied in the field of pipe fittings production and can solve problems such as the inner wall of the pipe is not smooth, the outer surface is not smooth, etc., and achieve the effects of stable air pressure, reduced production costs, and smooth airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below.

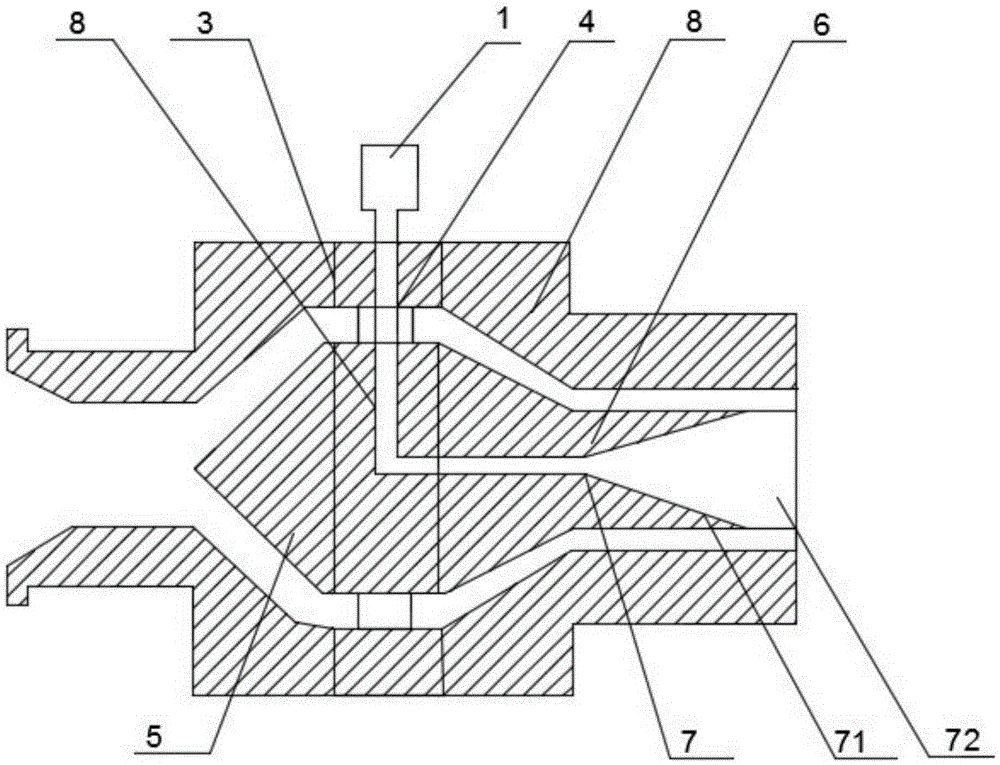

[0012] Such as figure 1 As shown, the present invention includes a flow divider 5, a support 3, a die 8, a mandrel 6, and an air guide tube 2. The flow divider 5 is fixed on the support 3, and the air inlet 4 is set on the support 3. The guide The trachea 2 is also fixed on the bracket 3, one end of the air guide tube 2 communicates with the air inlet 4, and the other end communicates with the central through hole 7 on the mandrel 6, and it is characterized in that the central through hole 7 is far away from the air guide tube One end of 4 is connected with a conical buffer pipe 71, and this buffer pipe 71 is connected with the buffer zone 72, and the buffer zone 72 is a circular tube, and its inner diameter is not greater than the inner diameter of the die 8. The axial length of the buffer zone 72 is 10-20 cm. The axial length of the buffer tube 71 is 20-30 cm. The water filter air pressure regulating device 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com