A and B glue dispenser

A technology of glue machine and glue point, which is applied in the direction of coating, surface coating liquid device, etc., can solve the problems of dispensing, lower production efficiency, deformation of valve channel and valve port, etc., to save replacement time and positioning Time, improve production efficiency, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

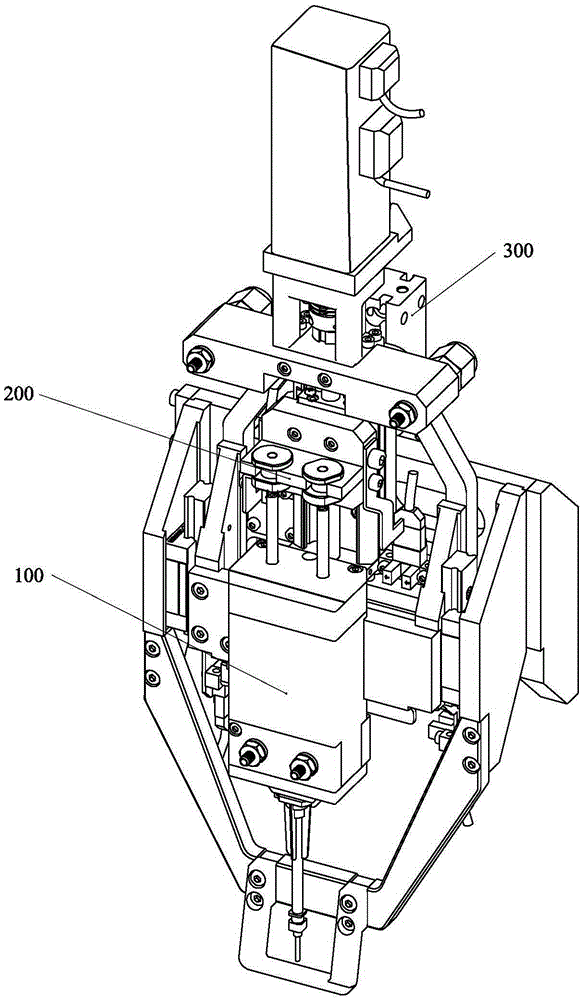

[0019] refer to Figure 1 to Figure 6 As shown, the AB glue dispensing machine of the present invention is composed of a set of plunger type glue dispensing valve 100, a set of mechanism 200 for precisely controlling the amount of glue, and a set of mechanism 300 for quickly replacing the mixing tube and needle.

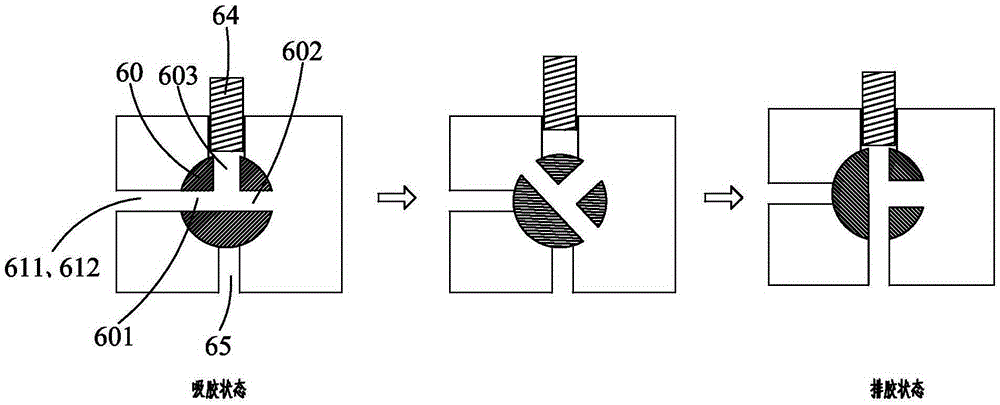

[0020] The plunger type glue dispensing valve 100 includes two separately separated cavities, respectively A glue temporary storage cavity 611 and B glue temporary storage cavity 612, each cavity has a rotary switch valve 60, and the switch valve 60 is provided with a glue inlet 601, a glue outlet 602 and an air filling port 603 that are connected to each other. At the glue port 602, the two switching valves 60 rotate simultaneously to switch.

[0021] The plunger type dispensing valve 100 has two working states, which are the glue feeding state and the glue discharging (glue dispensing) state. In the glue feeding state: the two rotary switching valves 60 correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com