Methods and apparatus using refrigerant compositions comprising refrigerant and lubricant comprising perfluoropolyether and non-fluorinated lubricant

A non-fluorinated lubricant, perfluoropolyether technology, applied in the direction of lubricating compositions, chemical instruments and methods, heat exchange materials, etc., can solve problems such as unaware of the immiscibility of PFPE and non-fluorinated lubricants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0107] The concepts disclosed herein will be further described in the following examples, which do not limit the scope of the invention described in the claims.

[0108] The following material was used in the implementation examples;

[0109] PAGPSD1 is a polyalkylene glycol lubricant available from AC Delco, Grand Blanc, Michigan; POERL22H, POERL32H, and POERL68H are available from Nu-Calgon, St.Louis, Missouri. , Missouri)) with the trademark Polyol ester lubricants for sale; GPL104, GPL105, and GPL106 are non-functionalized perfluoropolyethers available from DuPont, Wilmington, Delaware; 157FS(L) is a functionalized perfluoropolyether from DuPont, Wilmington, Delaware; HFC-1234yf (2,3,3,3-tetrafluoropropene) refrigerant was obtained from DuPont of Wilmington.

example 1

[0111] Miscibility

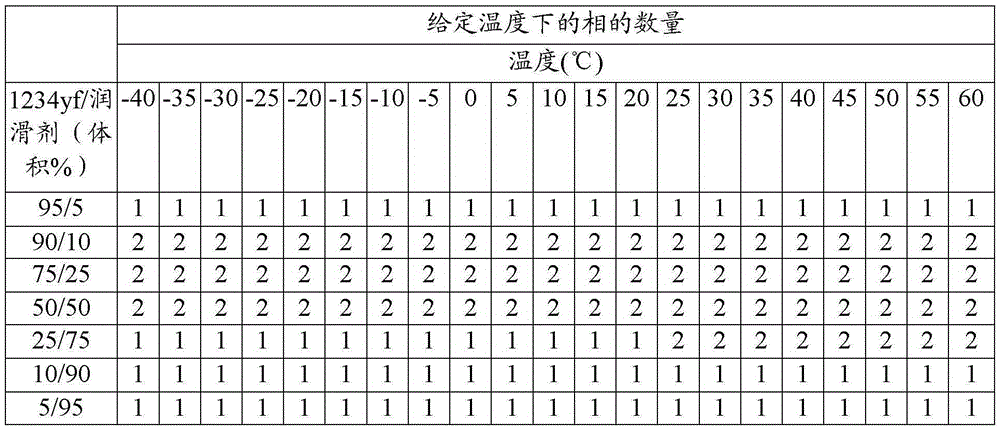

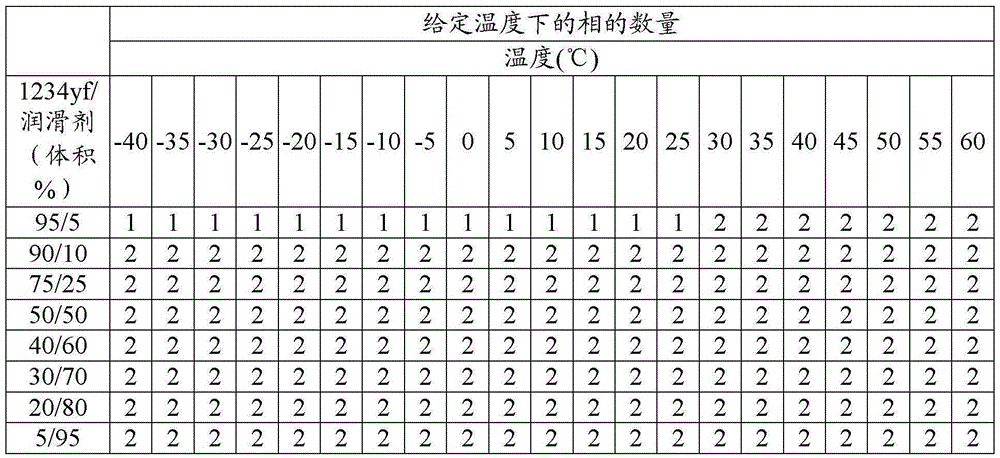

[0112]The miscibility of the lubricant mixture in the presence of refrigerant was tested by the following method. The refrigerant and lubricant mixture compositions were loaded into sealed glass tubes at different concentrations of refrigerant and lubricant by volume. In most cases, HFO-1234yf refrigerant, one PFPE lubricant and one non-fluorinated lubricant were loaded into the tubes. The tubes were then subjected to different temperatures and the amount of phase present was visually observed. If one phase is observed, the refrigerant has achieved complete miscibility with both lubricants. If three phases are observed, miscibility has not been achieved between any of the phases. It is desirable to have one or two phases to show improved miscibility. The results are shown in Tables 1 to 12. Table 1 shows miscibility data for pure PAG with HFO-1234yf refrigerant. Table 2-4 shows the Miscibility data for 104 / PAG / 1234yf; Tables 5-8 show Miscibilit...

example 2

[0170] viscosity

[0171] In order to select a preferred PFPE lubricant to replace a PAG or POE lubricant, it is important to determine the viscosity of the refrigerant / lubricant mixture at compressor sump conditions during refrigeration or air conditioning operation. The gas liquid equilibrium, pressure and viscosity data of PAG and POE lubricants with HFO-1234yf were measured and compared with HFO-1234yf and different PFPE lubricants. The viscosity of the refrigerant-lubricant mixture was determined at typical compressor sump conditions of 20° C. and 0.35 MPa using a ViscoPro 2000 viscometer (Cambridge Applied Systems, Medford, Massachusetts, USA). Results are shown below.

[0172] Table 15

[0173]

[0174]

[0175] The data indicate that for PAGPSD1 the closest match in terms of viscosity is GPL104, both have a viscosity of 3cP. GPL-104 is also the best choice because it matches or slightly exceeds the viscosity of the POE lubricant being replaced, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com