Piercing mandrel having an improved service life for producing seamless tubes

A technology of seamless pipes and punches, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of increasing service life, unable to cool the top of punches, complex production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

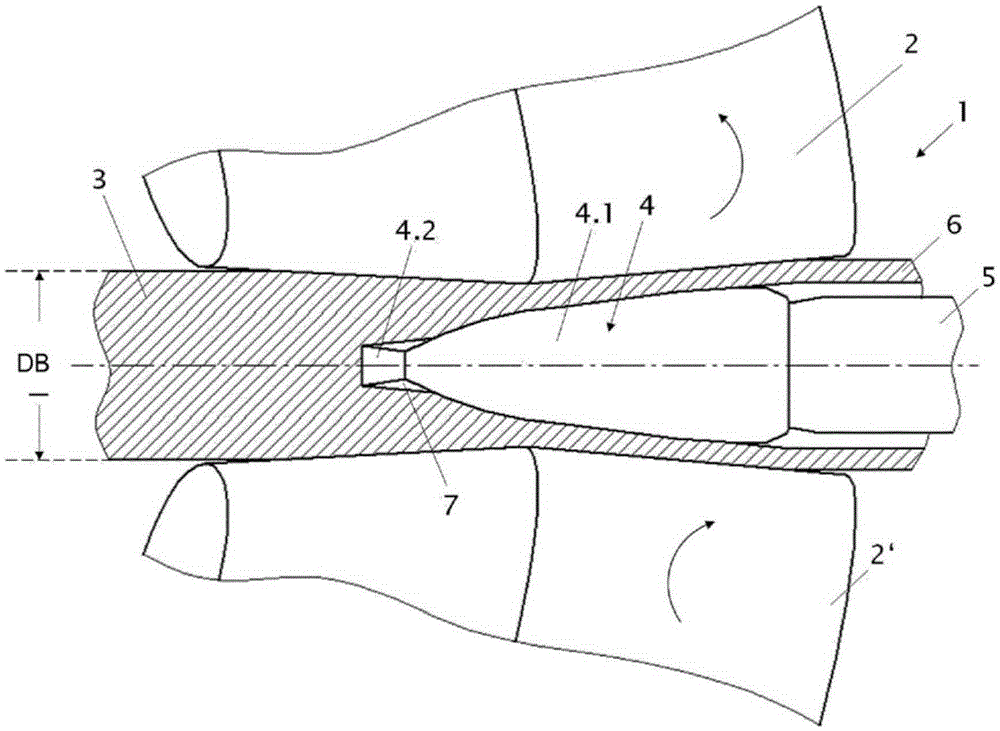

[0032] figure 1 A conical piercing mill is shown. This conical piercing mill utilizes the punch of the present invention to form a solid block of steel into a hollow block tube. The conical piercing mill 1 comprises two work rolls 2, 2'. These two work rolls form the solid block 3 into a hollow block tube 6 with internal tooling. The internal tools include the punch 4 and mandrel 5 of the present invention. In the opposite direction to the direction of rotation of the work rolls 2, 2', the solid block 3 or hollow block tube 6 is moved in a helical fashion by axially fixed internal tools.

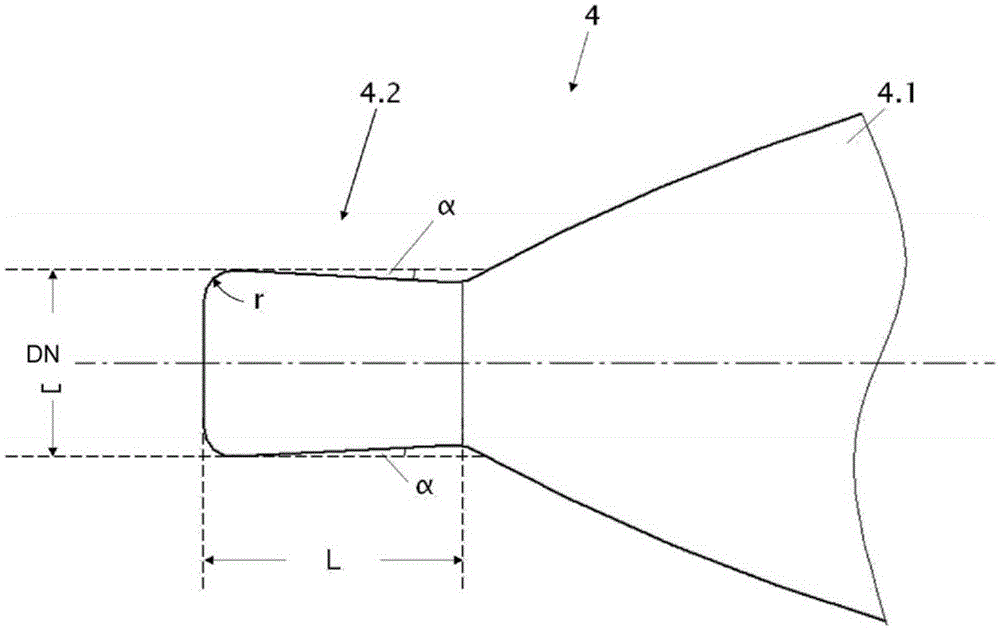

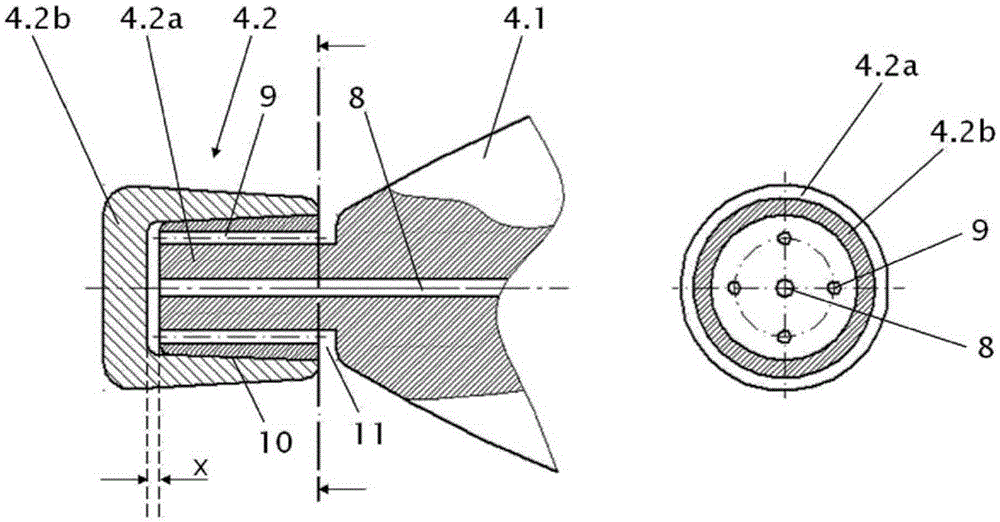

[0033] According to the invention, the punch 4 comprises a punch body 4.1 to which a punch nose 4.2 is connected. The diameter of the punch body 4.1 increases continuously from the nose side to a maximum value which determines the inner diameter of the hollow block tube 6 . According to the invention, the punch nose 4.2 has a diameter that decreases conically towards the punch body 4.1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com