A kind of flexible display substrate and preparation method thereof

A flexible display and flexible substrate technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as gassing, affecting yield, material stability, etc., achieving simple film forming operations and cost savings , the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

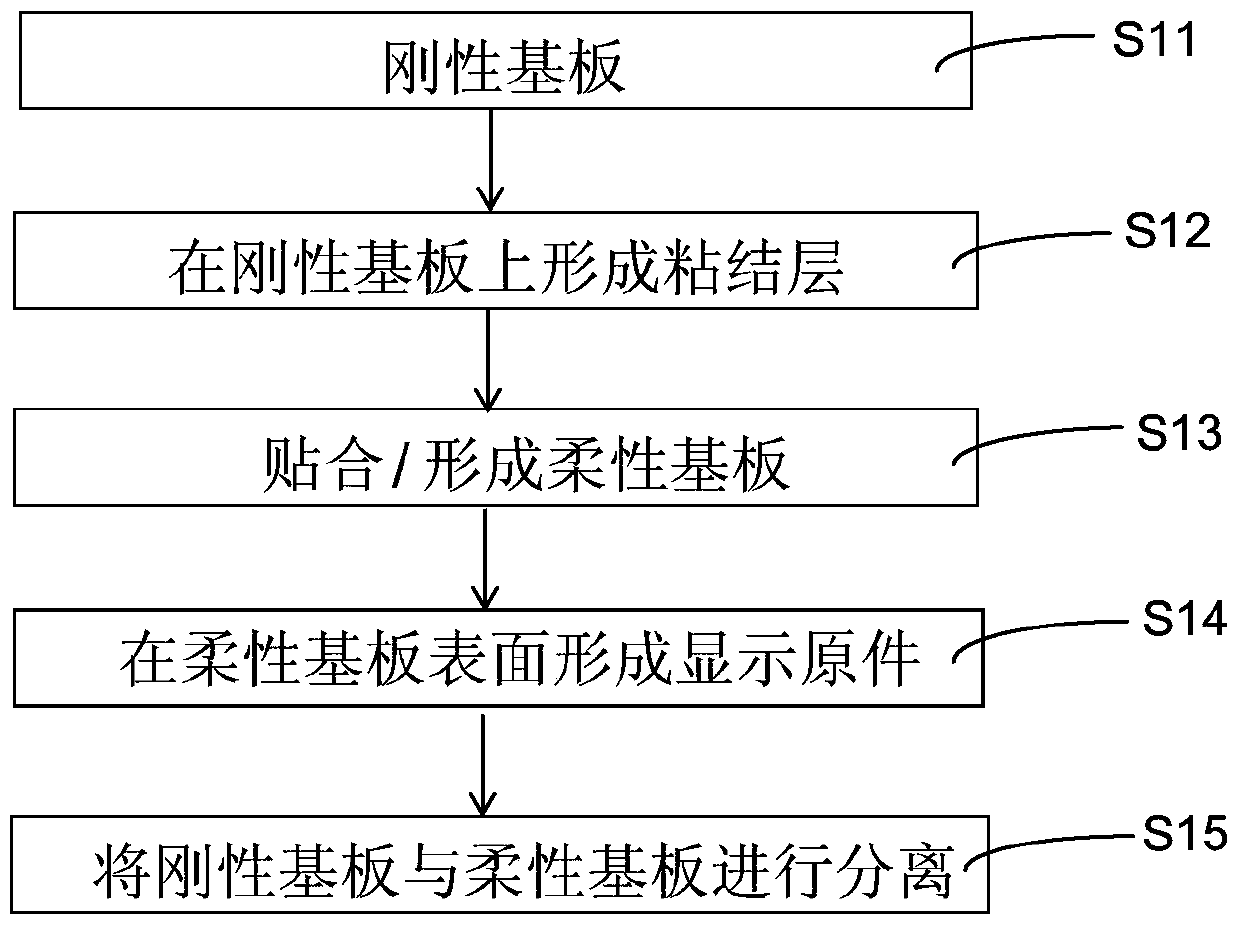

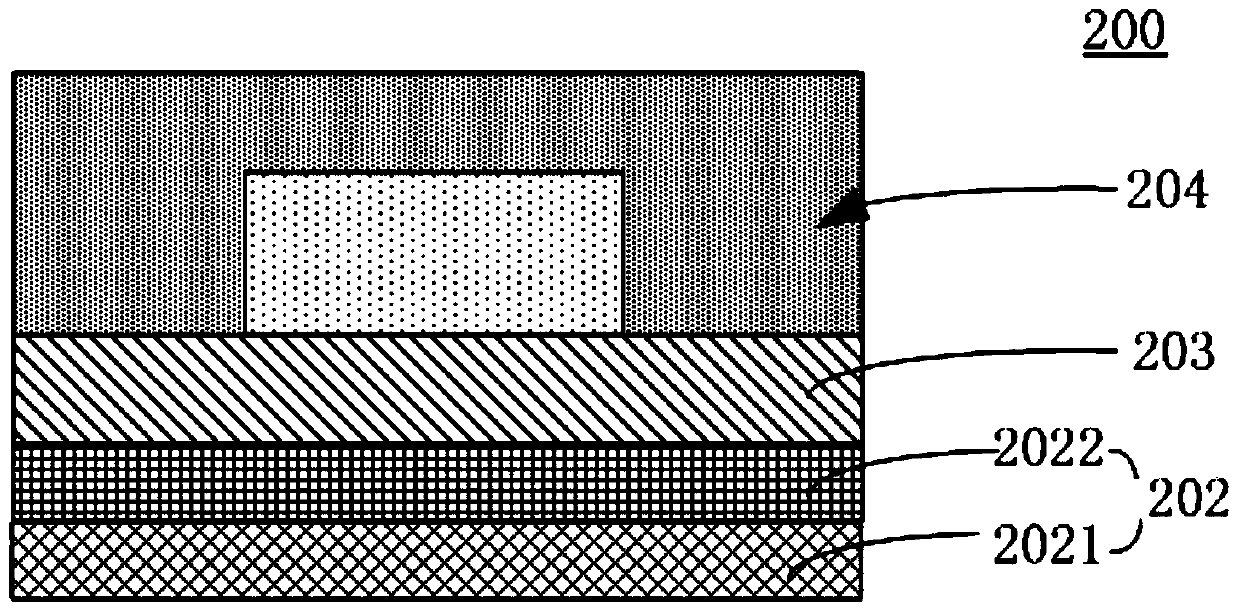

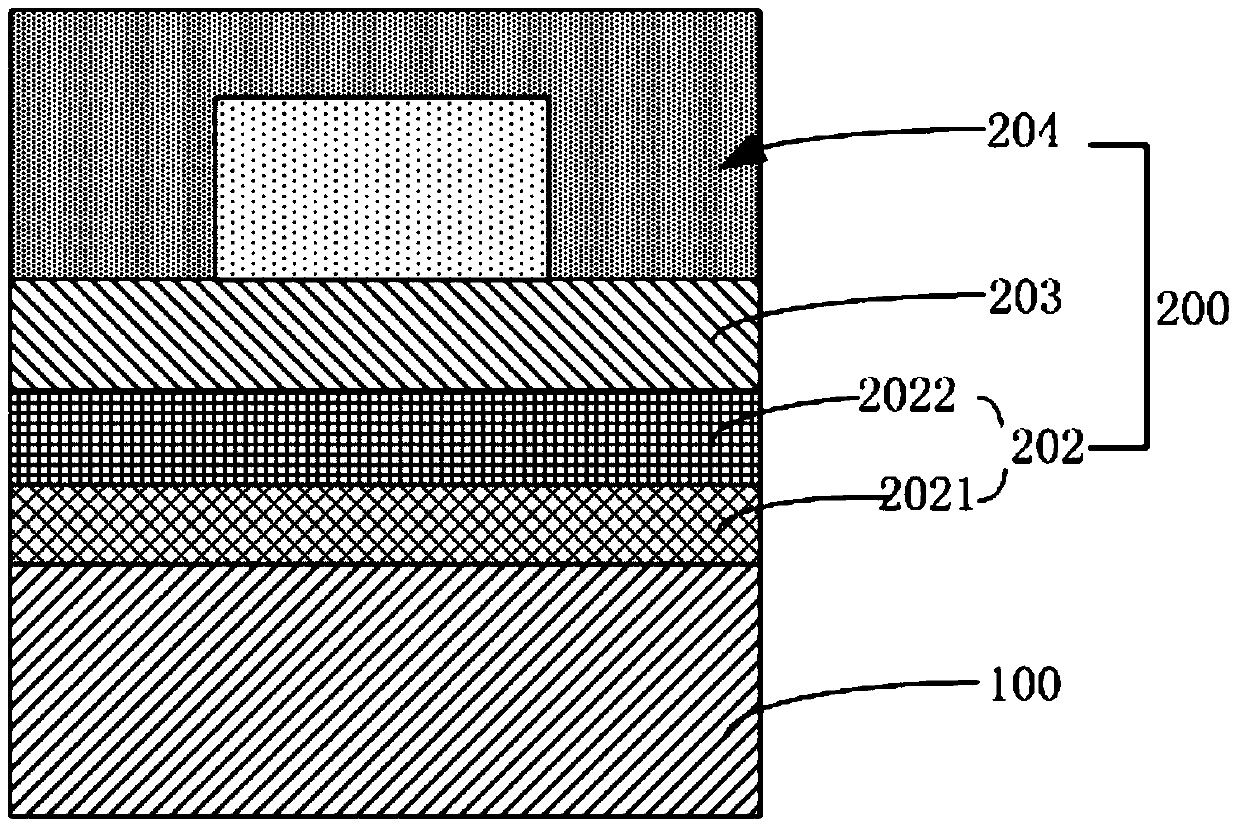

[0038] Such as figure 2 Shown is a schematic cross-sectional view of a flexible display substrate 200 according to Embodiment 1 of the present invention, including a flexible substrate 203;

[0039] set on the first surface of the flexible substrate 203 (ie, as figure 2 display element 204 on the upper surface shown); and

[0040] set on the second surface of the flexible substrate (ie figure 2 The release layer structure 202 on the lower surface shown),

[0041] The release layer structure 202 includes at least one release layer 2021;

[0042] The release layer 2021 is an inorganic material containing intermolecular hydrogen bonds.

[0043] The release layer 2021 of the flexible display substrate provided in this embodiment is an inorganic material containing intermolecular hydrogen bonds. Bubbles are generated due to the influence of temperature during the manufacturing process, which ensures the flatness requirements of the display device during the manufacturing pr...

Embodiment 2

[0082] The difference between the flexible display substrate structure of Embodiment 2 and Embodiment 1 lies in that the structure of the release layer is different.

[0083] Such as Figure 5 Shown is a schematic cross-sectional view of a release layer structure 200' according to Embodiment 2 of the present invention. In the release layer structure 202', release layers 2021' and water blocking layers 2022' are arranged alternately.

[0084] In a modified implementation of Example 2, the release layer structure 202' is a structure in which the release layer 2021' and the water blocking layer 2022' are alternately arranged three times or more.

[0085] Regarding the preparation method of the flexible display substrate in Example 2, the difference from Example 1 is: 1) Forming the release layer structure 202' on the support carrier includes: the release layer 2021' and the water blocking layer 2022' are formed alternately.

[0086] Specifically, the release layer structure 202...

Embodiment 3

[0091] In embodiment 3, the same part as embodiment 2 will not be repeated here, the difference is that the release layer structure is a sandwich structure of "water blocking layer-central layer-release layer", wherein the water blocking layer It is directly combined with the flexible substrate, and the release layer is directly combined with the support carrier; the central layer can be one or more layers, and can be an inorganic material layer or an organic material layer, as long as it is not affected by temperature in the subsequent manufacturing process. and other reasons affect the flatness of the flexible substrate. Of course, the release layer structure may also be a structure in which the above-mentioned sandwich structure is alternately arranged multiple times.

[0092] In yet another embodiment of embodiment 3, the same structure as the first embodiment of embodiment 3 will not be repeated, the difference is that the release layer is not directly combined with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com