A capacitive equipment live detection final screen sampling device

A capacitive equipment, live detection technology, applied in the direction of measuring device, measuring device casing, measuring current/voltage, etc., can solve the problems of insufficient safety distance, low efficiency, and inability to carry out live detection work in insulation state, to prevent equipment The effect of failure, preventing errors, and ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

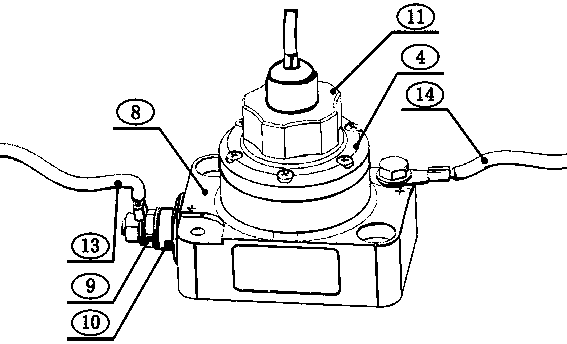

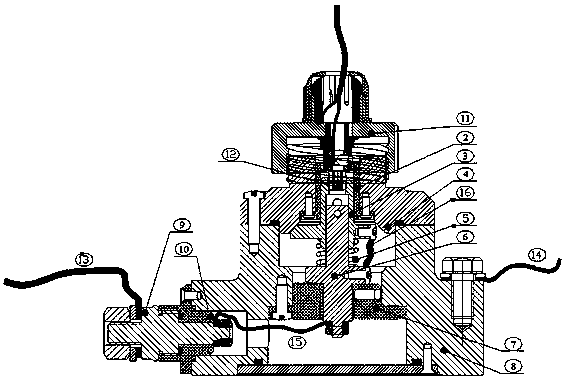

[0024] The present invention is a capacitive equipment live detection final screen sampling device, which includes an upper rotating mechanism, a middle rotating wiring mechanism and a bottom fixing mechanism. The rotating mechanism is connected to the rotating wiring mechanism, and the lower part of the rotating wiring mechanism is connected and fixed. mechanism.

[0025] The rotating mechanism includes: a sealing cover 1 , a detection joint 11 and a detection core 12 . Wherein the sealing cover 1 is used for sealing the equipment when not in detection. The sealing cover 1 can be covered on the detection joint 11, and the detection core 12 is connected to the detection joint 11. When performing detection, a detection joint 11 with a detection core 12 is used.

[0026] The rotary wiring mechanism includes: insulating guide sleeve 2 , sliding contact 3 , ground cover 4 , return spring 5 and flexible wire 16 . The sliding contact 3 is connected to the conductive column 6 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com