Method for measuring residual stress generated by metallic material pressure processing

A technology of metal materials and residual stress, which is applied in the measurement of the elastic deformation force of the measurement gauge, etc., can solve the problems of complex steps and damage to the measurement material, and achieve the effect of convenient operation, less consumables and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for measuring residual stress produced by press processing of metal materials, specifically comprising the steps of:

[0036] (1) First measure the specific volume of the metal material to be tested:

[0037] First cut the pressure-processed metal material to be tested into several samples with a mass greater than 1g according to different parts, and measure the specific volume, and then measure the specific volume of the metal material to be tested before pressure processing (annealed state);

[0038] The used instrument of quality measurement in the embodiment of the present invention is CP153 type electronic digital balance, and the sensitivity is 10 -3 g, the relative measurement accuracy of an object with a mass of 10g can reach 0.01%.

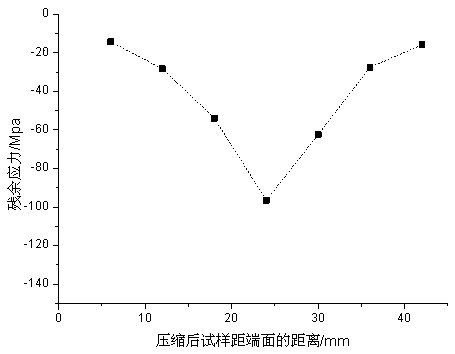

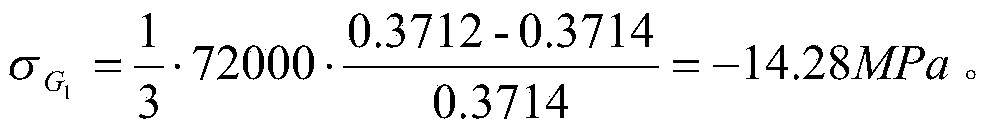

[0039] The material to be analyzed and tested is a deformed aluminum alloy with a grade of 6XXX. The purpose of the analysis is to measure the distribution of residual stress inside the material after press processing (up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com