Automobile spare and accessory part baking assembly line

A spare parts and assembly line technology, applied in the field of auto parts casting, can solve the problems of reducing production efficiency, increasing production cost, insufficient baking degree, etc., and achieve the effect of accelerating baking speed, increasing production cost and reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

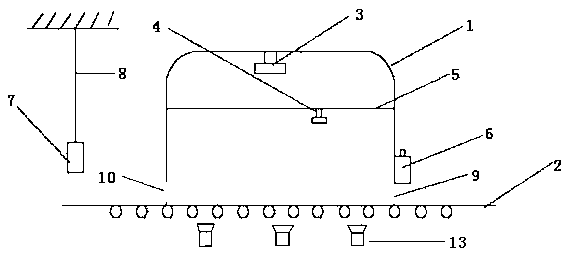

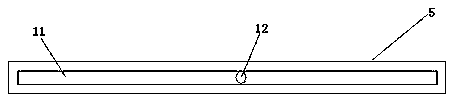

[0013] Example: such as figure 1 And as shown in 2, a baking assembly line for auto parts is composed of a baking oven 1 and a transmission device 2, the transmission device 2 includes a conveyor belt and a transmission wheel, the baking oven 1 is arranged above the conveyor belt, and the baking oven 1 is set There is an inlet 9 and an outlet 10, a heater 3 is arranged on the top of the oven 1, a guide rail 5 across the oven 1 is arranged in the middle of the oven 1, and a track 11 is installed on the guide rail 5, and a slider 12 is installed on the track 11 , the slider 12 can freely slide back and forth in the track 11, the fan 14 is fixedly arranged on the slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com