Fan control circuit

A fan control and circuit technology, applied in pump control, non-variable pumps, machines/engines, etc., can solve problems such as temperature sensitivity, different temperature resistance values, and inability to meet chip heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

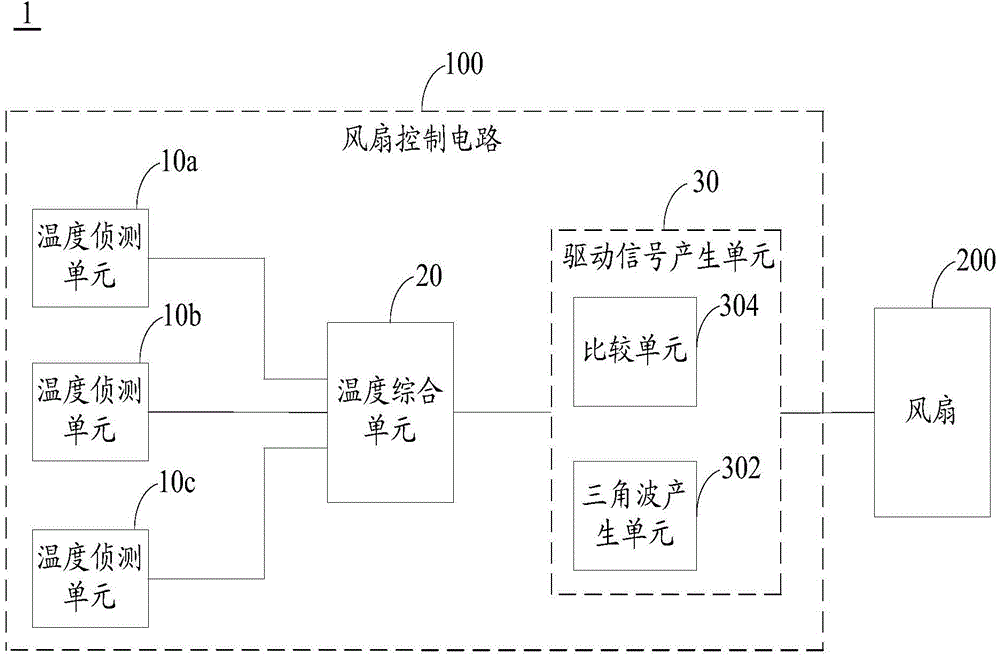

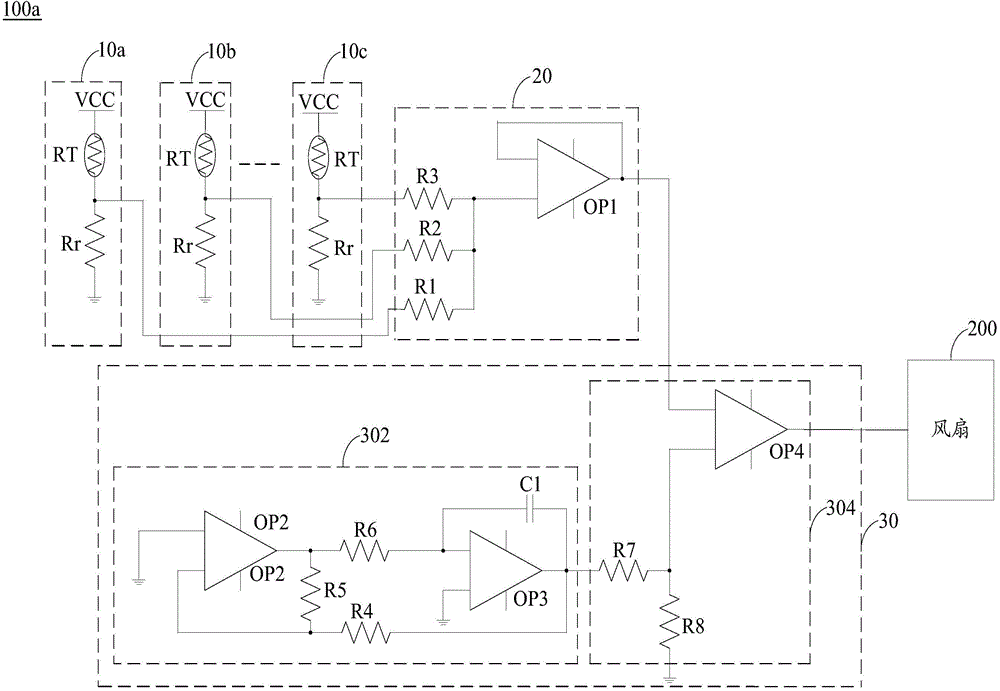

[0032] figure 1 It is a block diagram of the fan control circuit 100 in an embodiment of the present invention. In this embodiment, the electronic device 1 includes a plurality of heating elements (not shown in the figure), a fan control circuit 100 and a fan 200, wherein the fan control circuit 100 is used to control the rotation of the fan 200 to achieve active heat dissipation, thereby ensuring that the electronic Device 1 does not overheat during operation. The fan control circuit 100 includes a plurality of temperature detection units 10a, 10b, 10c (in this embodiment, only three are used as an example, but not limited to three, and may include less than or more than three temperature detection units ), the temperature integration unit 20 and the drive signal generation unit 30. Each temperature detection unit 10a, 10b, 10c detects the temperature of a heating element and outputs a corresponding temperature detection signal. In this embodiment, the plurality of heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com