Wind power blade root extension component and manufacturing method thereof

A technology of wind turbine blades and extensions, which is applied to the components of wind power generation equipment, components of wind turbine blade root extensions and their manufacturing fields, and can solve the problem that wind turbines do not reach the expected wind speed and power, the operating load does not have the expected value, and it is not easy to wind. Resource conditions and other issues can be avoided to avoid wrinkles, reduce loads, and facilitate bolt replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

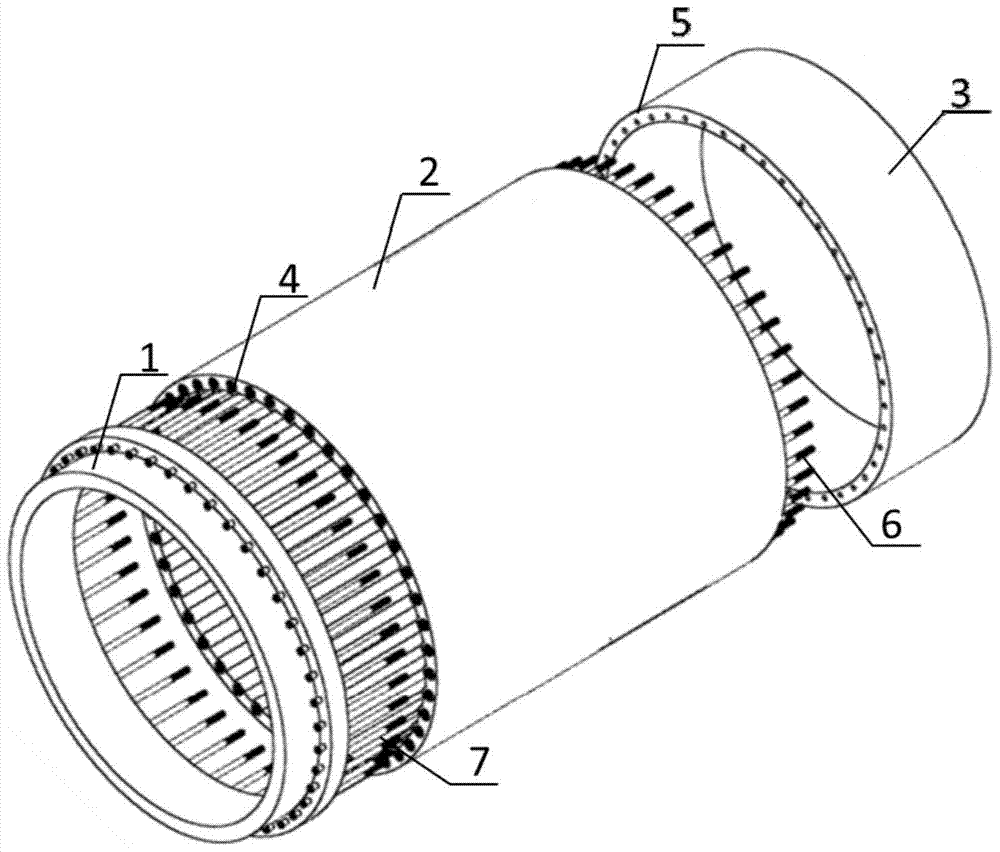

[0045] Such as figure 1 , 2 As shown, the wind power blade root extension component provided by the present invention is a hollow cylindrical shell structure placed between the original wind power blade and the wind turbine hub, one end is connected to the hub connecting flange 1 with a flange connection bolt 7, and the other end The blade root connecting bolt 6 is used to connect the blade root 3 to increase the length of the blade and improve the power generation efficiency.

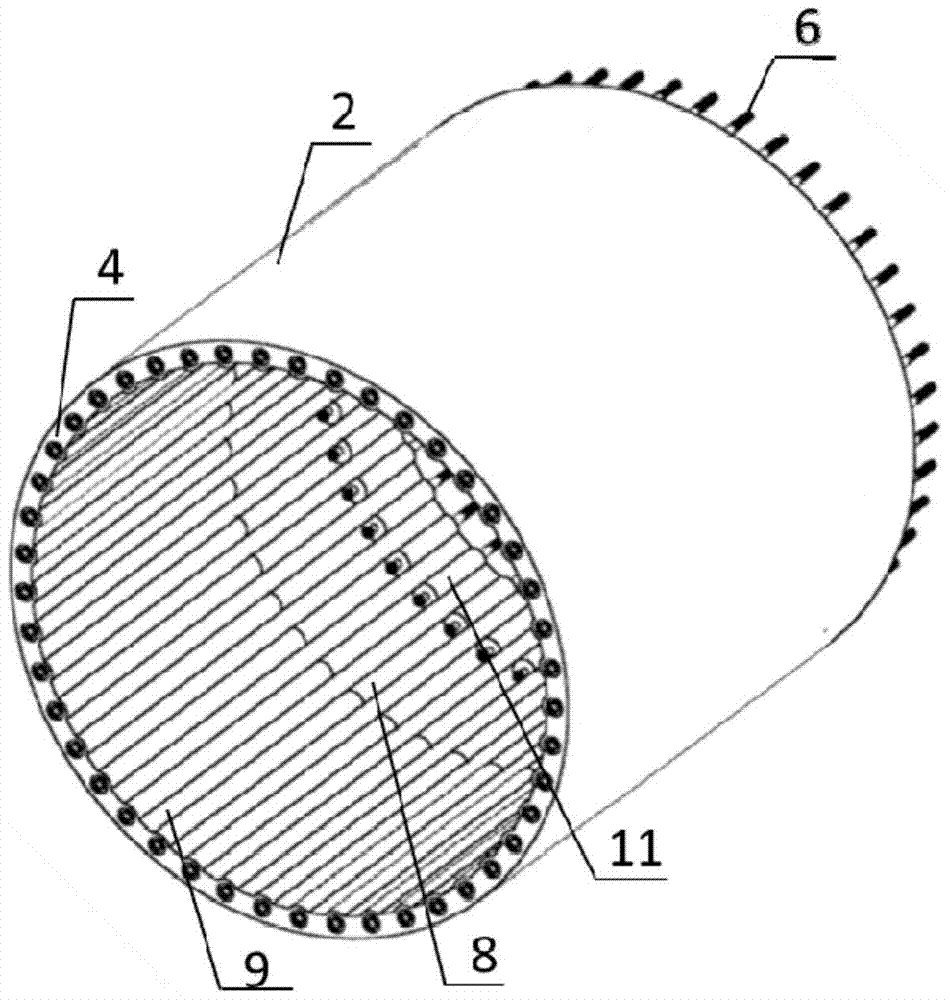

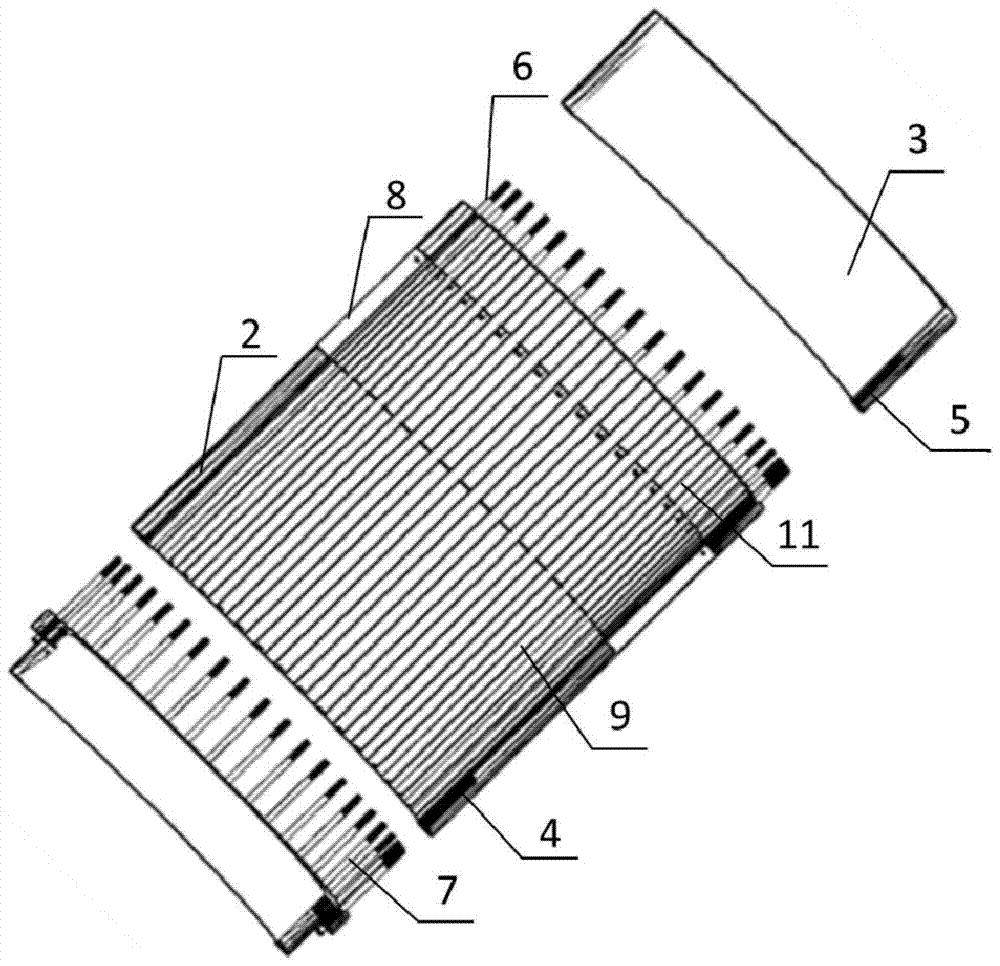

[0046] Such as image 3 , 4 As shown, the flange connection bolt 7 connects the extension section main body 2 with the hub of the wind turbine, and the blade root connection bolt 6 passes through the metal sleeve 11 arranged on the extension sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com