Method for improving viscosity, thermo-stability and browning degree of extruded broken rice inverted syrup

A technology for inverting syrup and thermal stability, applied in the fields of starch deep processing and food processing, can solve the problems of extruded broken rice inverting syrup viscosity, low thermal stability browning degree, etc., to shorten saccharification time, reduce costs, and improve browning Variation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

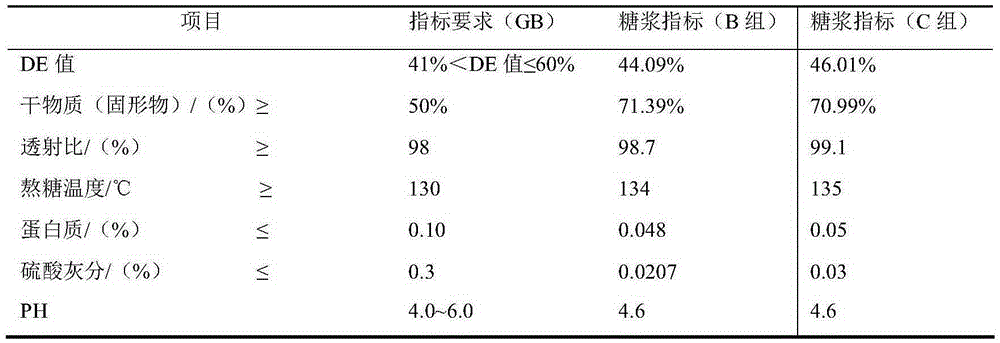

Image

Examples

Embodiment 1

[0064] A method for improving the viscosity, thermal stability and browning degree of extruded broken rice invert syrup, characterized in that the method comprises the following steps:

[0065] (1) Extrusion treatment of broken rice: take the pulverized broken rice, adjust its moisture to 17%, and then use a twin-screw extruder to extrude under the condition of 140 rpm, and the feed rate is 10 kg / h, Finally, it is dried and pulverized, filtered through an 80-mesh sieve to obtain uniform rice noodles for later use; the extruder sleeve is divided into four temperature zones in turn, the temperature of the first zone is 30°C, the temperature of the second zone is 65°C, and the temperature of the third zone is 105°C , the pressure of the third zone is 19MPa, the temperature of the fourth zone is 65℃, and the heating residence time of each zone is equal;

[0066] (2) Preparation of broken rice invert syrup: the extruded rice flour obtained in step (1) is slurried with water at a ma...

Embodiment 2

[0072] A method for improving the viscosity, thermal stability and browning degree of extruded broken rice invert syrup, characterized in that the method comprises the following steps:

[0073] (1) Extrusion treatment of broken rice: take the crushed broken rice, adjust its moisture to 21%, and then use a twin-screw extruder to extrude under the condition of 160 rpm, the feeding rate is 12 kg / h, and finally Dry and pulverize, and filter through an 80-mesh sieve to obtain uniform rice noodles for later use; the extruder sleeve is divided into four temperature zones in turn, the temperature of the first zone is 40°C, the temperature of the second zone is 70°C, and the temperature of the third zone is 115°C. The pressure of the third zone is 19MPa, the temperature of the fourth zone is 70℃, and the heating residence time of each zone is equal;

[0074] (2) Preparation of broken rice invert syrup: the extruded rice flour obtained in step (1) is slurried with water according to the r...

Embodiment 3

[0080] A method for improving the viscosity, thermal stability and browning degree of extruded broken rice invert syrup, characterized in that the method comprises the following steps:

[0081] (1) Extrusion treatment of broken rice: take the crushed broken rice, adjust its moisture to 17%, and then use a twin-screw extruder to extrude under the condition of 140 rpm, the feeding rate is 11 kg / h, and finally Dried and pulverized, and filtered through an 80-mesh sieve to obtain uniform rice noodles for later use; the extruder sleeve is divided into four temperature zones in turn, the temperature of the first zone is 30--40 °C, the temperature of the second zone is 68 °C, and the temperature of the third zone is 110℃, the pressure of the third zone is 16MPa, the temperature of the fourth zone is 68℃, and the heating residence time of each zone is equal;

[0082] (2) Preparation of broken rice invert syrup: the extruded rice flour obtained in step (1) is slurried with water at a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com