Pneumatic tire

A technology of pneumatic tires and treads, which is applied to special tires, tire parts, and no separate inflatable pads, etc., can solve problems such as shortening tire life, and achieve the effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

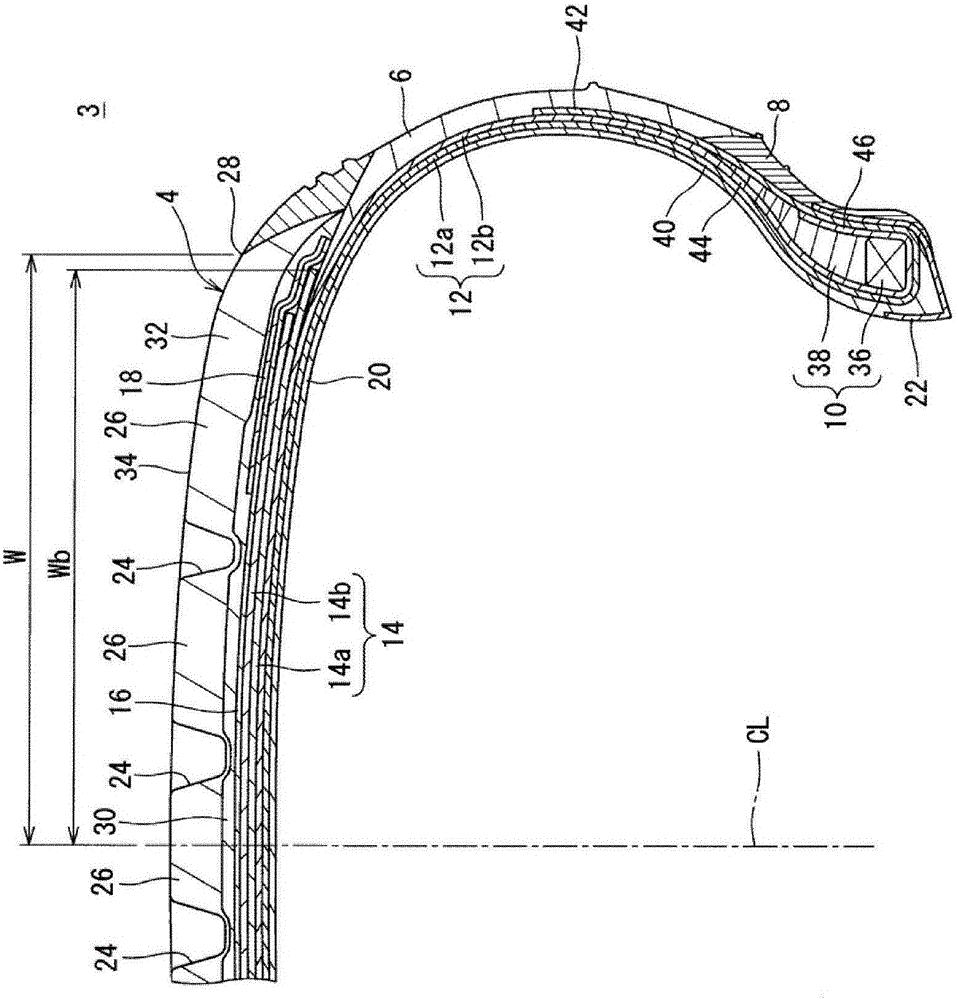

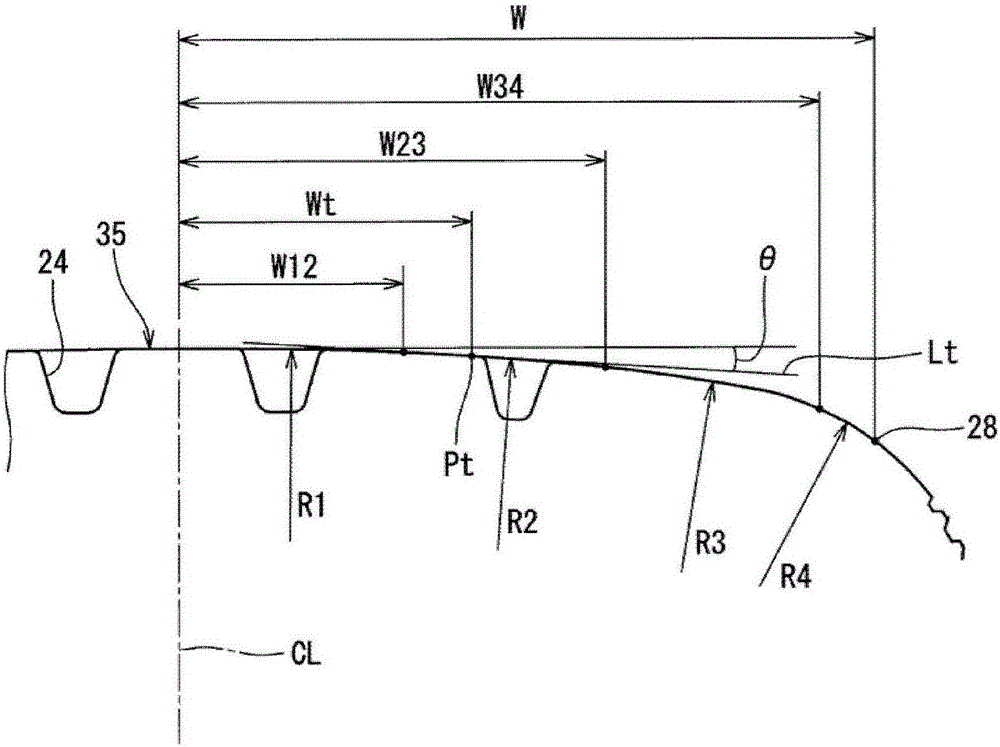

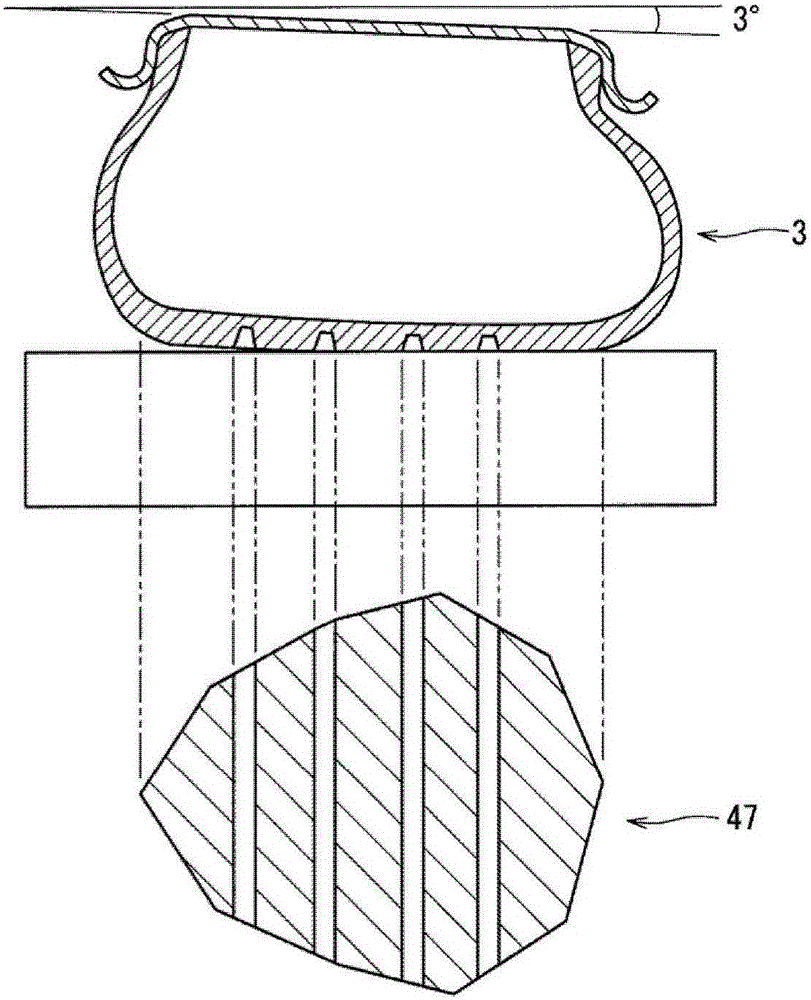

[0111] obtain figure 1 The tire of Example 1 of the structure shown. The size of this tire is 235 / 45R17. Each element of this tire is shown in Table 1. The width Wt shows values when θ is 3° and when θ is 5°. In this tire, the number of arcs constituting the outer shape is four.

Embodiment 2

[0115] obtain figure 1 The tire of Example 2 of the structure shown. The size of this tire is 235 / 60R18. Each element of this tire is shown in Table 1. In this tire, the number of arcs constituting the outer shape is four.

Embodiment 3

[0119] obtain figure 1 The tire of Example 3 of the structure shown. The size of this tire is 215 / 60R16. Each element of this tire is shown in Table 1. In this tire, the number of arcs constituting the outer shape is three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com