Full-automatic coiled tape pasting and covering equipment

A fully automatic and pasting technology, which is applied in lamination devices, lamination auxiliary operations, lamination, etc., can solve the problems of tape tearing, uneven tape tension, low efficiency, etc., and achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

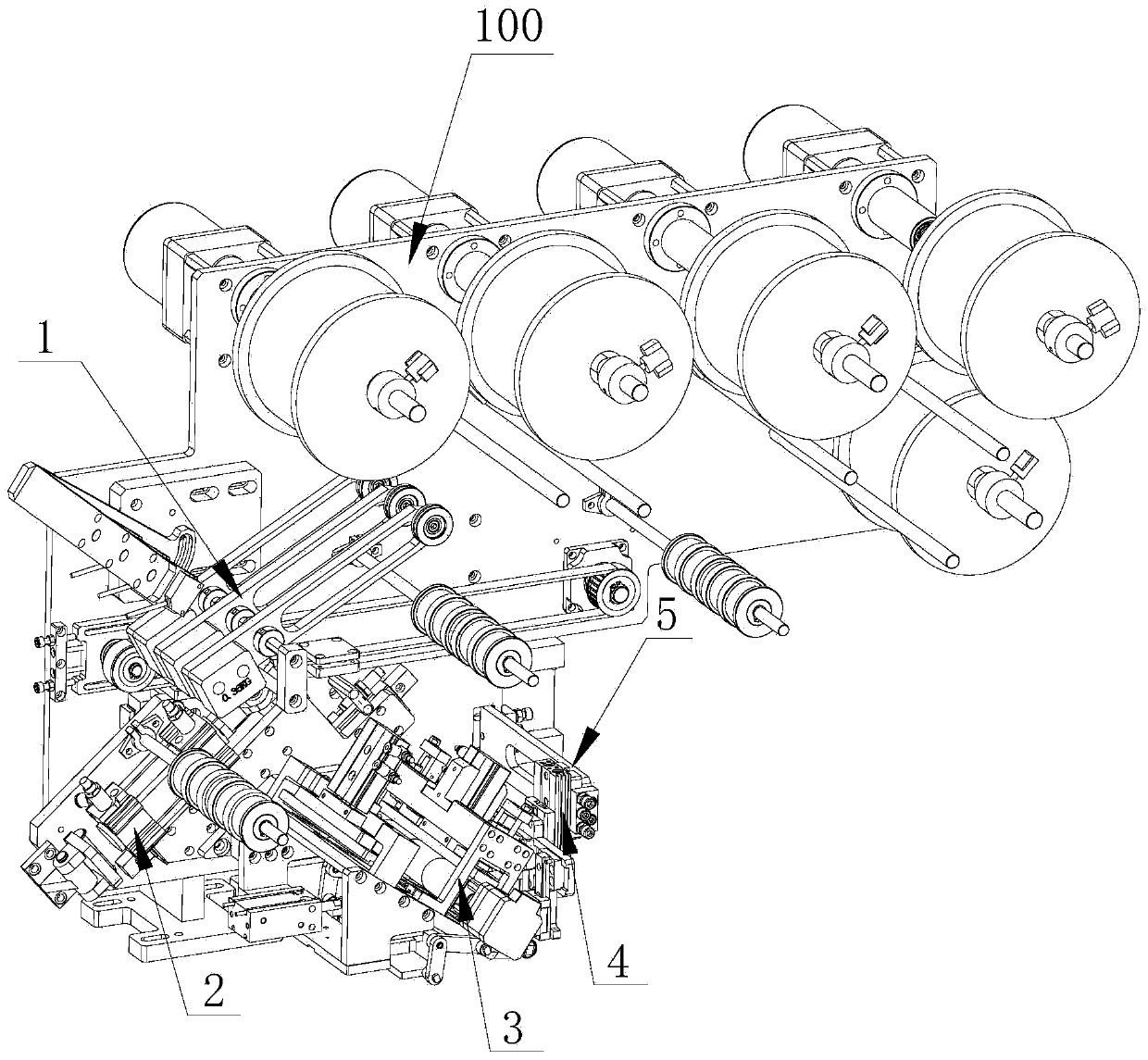

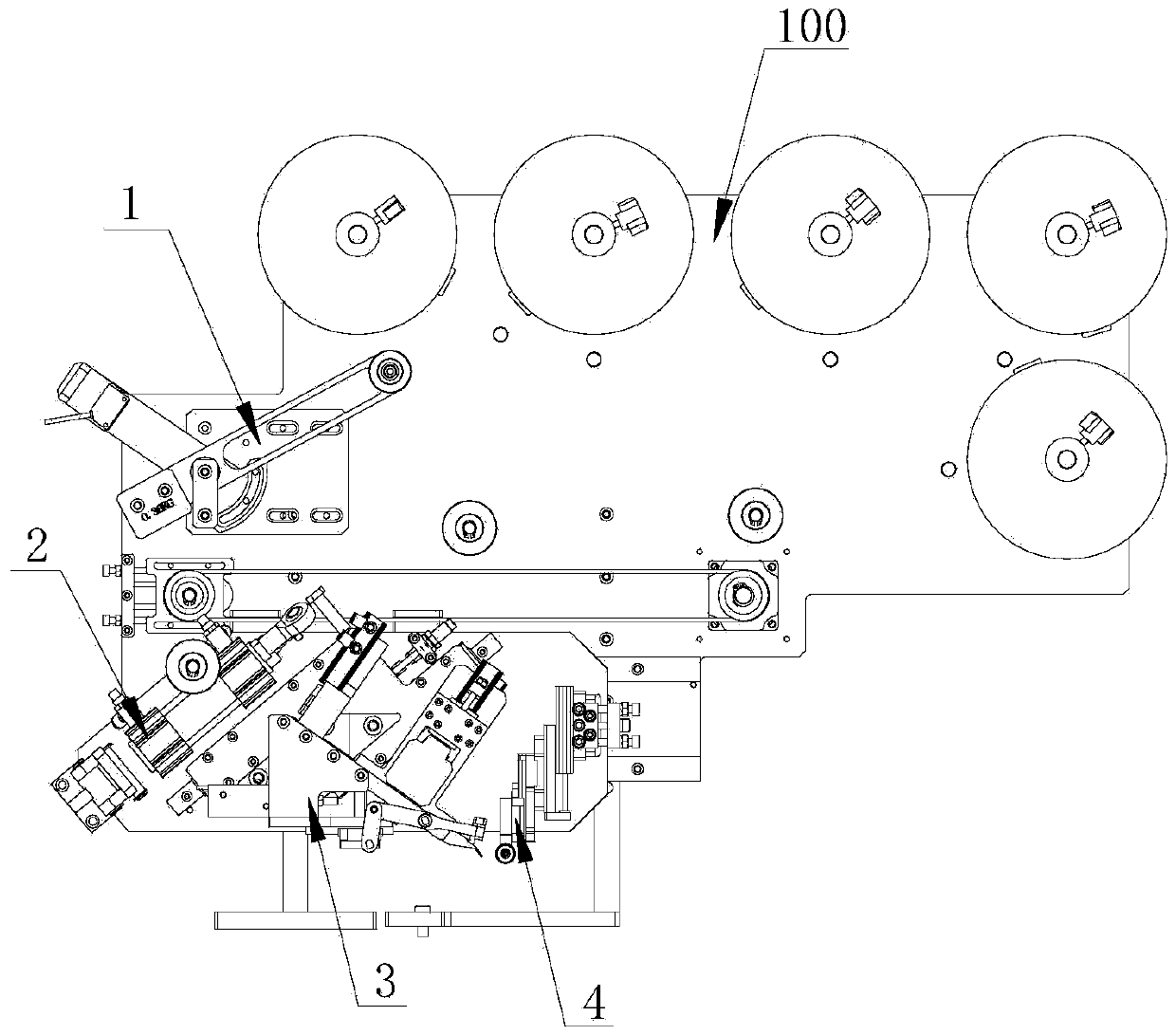

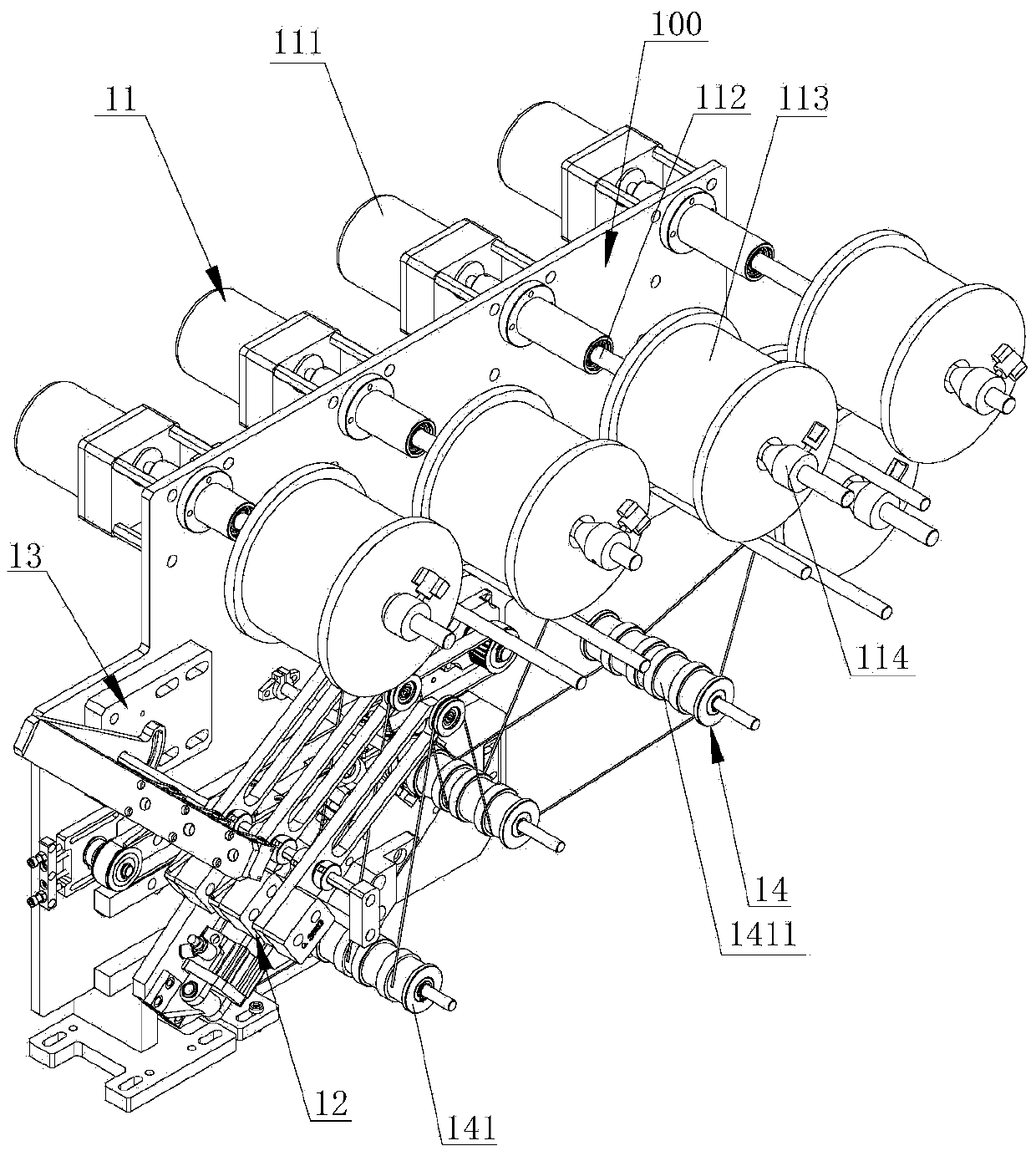

[0031] Such as figure 1 and figure 2 As shown, the fully automatic tape laminating equipment provided in this embodiment includes a mounting plate 100 , an unwinding buffer device 1 , a driving device 2 , a cutting device 3 and a laminating device 4 . The unwinding and buffering device 1 is fixed on the mounting plate 100 , and the unwinding and buffering device 1 pulls out the tape from the reel and buffers it by means of constant tension. The driving device 2 is arranged on the mounting plate 100, and the driving device 2 includes a first driving assembly 21 for driving the cutting device 3 and the application device 4 to reciprocate horizontally and a second driving assembly 22 for driving the cutting device 3 to move up and down. The cutting device 3 is connected to the driving device 2 and is arranged on one side of the unwinding buffer device 1 along the conveying direction of the tape, conveys the stretched tape and cuts the tape by using a plurality of split cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com