Soft mold and closed mold fiber reinforced composite product processing device and method

A fiber reinforced and composite material technology, applied in the soft mold closed mold fiber reinforced composite product processing device and processing field, can solve the problems of narrow application range, poor product surface quality, high raw material cost, and achieve low technical level requirements and product quality. High surface quality and highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

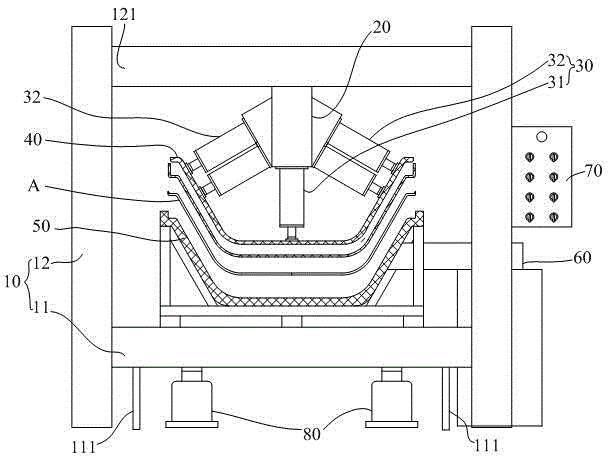

[0026] Reference figure 1 In this embodiment, a soft-mold closed-mold fiber-reinforced composite product processing device includes a mold fixing frame 10, a pressure fixing frame 20, a plurality of pressure components 30 arranged on the pressure fixing frame 20, an upper mold 40, The lower mold 50, the vibration device 60 and the electric control system 70, in the figure A is a product; the mold fixing frame 10 includes a base 11 and a support frame 12, the support frame 12 includes an upper beam 121, and the pressure fixing frame 20 is fixed on the upper beam 121 The plurality of pressing parts 30 includes at least one vertical pressing part 31 perpendicular to the upper mold 40; the upper mold 40 is located below the pressing part 30, which includes a thin-walled rigid mold shell 41 and a thin The flexible lining layer 42 on the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com