Liquid crystal display panel and display device

A technology of liquid crystal display panels and liquid crystals, applied in nonlinear optics, instruments, optics, etc., can solve problems such as good results, and achieve the effects of slowing down speed, improving puncture and liquid crystal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

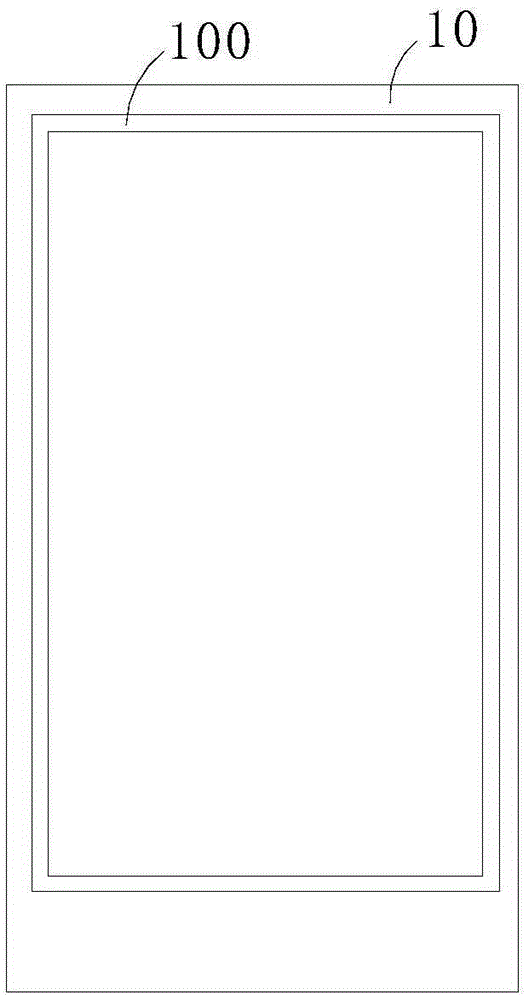

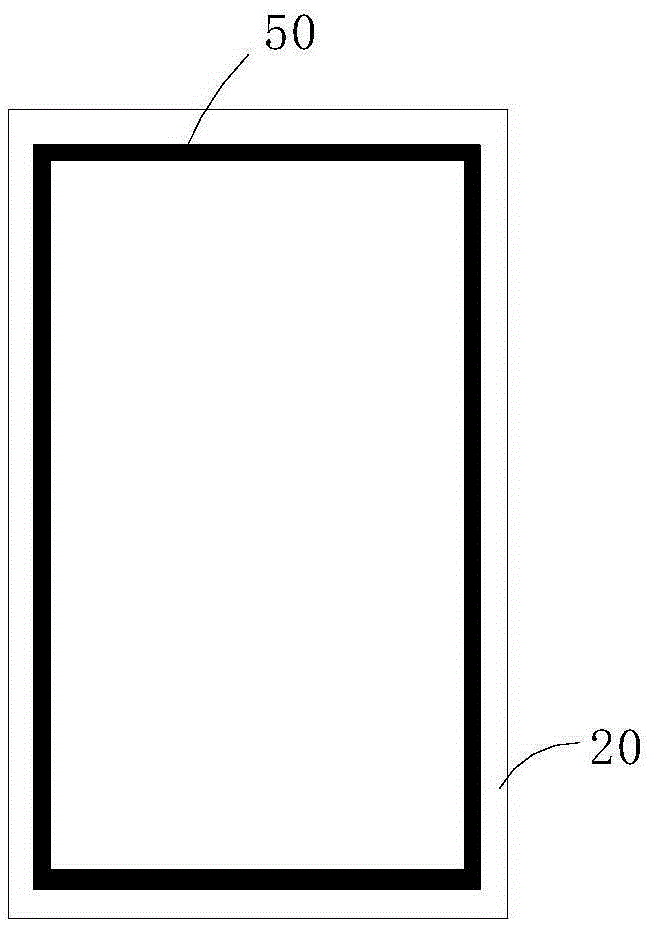

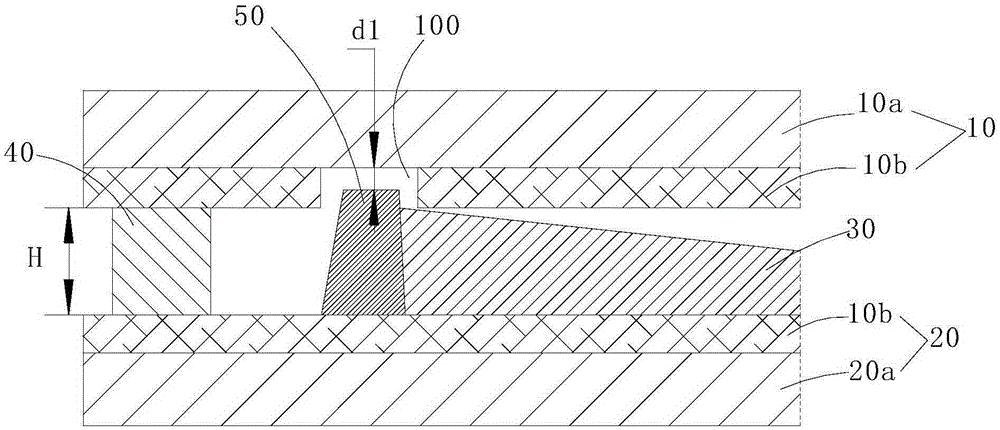

[0031] refer to Figure 1 ~ Figure 3 The liquid crystal display panel of the present invention includes an upper substrate 10, a lower substrate 20, a liquid crystal 30 filled between the upper substrate 10 and the lower substrate 20, a frame 40 forming a closed cavity with the upper substrate 10 and the lower substrate 20, and a frame 40 located in the frame 40 inside, a circle of first spacer retaining wall 50 located on the lower substrate 20, the height of the first spacer retaining wall 50 is higher than the thickness H of the box formed when the upper substrate 10 and the lower substrate 20 are paired, and the second A distance between the end surface of a spacer wall 50 and the inner surface of the upper substrate 10 forms a channel through which the liquid crystal 30 can flow. Here, the frame 40 is a frame-shaped sealant, which is disposed on the edges of the upper substrate 10 and the lower substrate 20 .

[0032] Here, the upper substrate 10 and the lower substrate ...

Embodiment 2

[0040] Such as Figure 7 , different from Embodiment 1, on the basis of it, the upper substrate 10 and / or the lower substrate 20 of this embodiment can also be provided with a columnar spacer column 70, the height of the spacer column 70 is less than the thickness H of the box, preferably the upper The spacer columns 70 on the substrate 10 and the spacer columns 70 on the lower substrate 20 protrude toward the middle alternately, which can block the flow velocity of the liquid crystal 30 to a certain extent, and the effect is more obvious when the number is large.

Embodiment 3

[0042] Such as Figure 8 Different from the above embodiments, the liquid crystal display panel of this embodiment also includes a circle of second spacer retaining walls 60 arranged on the upper substrate 10, and the height of the first spacer retaining walls 60 is higher than that of the upper substrate 10. The thickness H of the cell formed when the cell is aligned with the lower substrate 20 , and the space between the end surface of the second spacer wall 50 and the inner surface of the lower substrate 20 forms a channel through which the liquid crystal 30 can flow.

[0043] An annular second groove 200 is defined on the inner surface of the lower substrate 20 , and the end of the second spacer wall 60 extends into the second groove 200 and maintains a second gap d2 with the bottom surface of the second groove 200 . Wherein, the second spacer retaining wall 60 can also be multi-turn, and the second spacer retaining wall 60 is arranged alternately and at intervals, forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com