Steam sootblower for heat exchanger

A soot blower and heat exchanger technology, applied in lighting and heating equipment, combustion product treatment, combustion methods, etc., can solve the problems of long-term safe and stable operation, heat exchange area ash, heat exchange surface blockage, etc. Ensure long-term stable operation, prevent fouling and blockage, and reduce fouling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid in the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principles of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

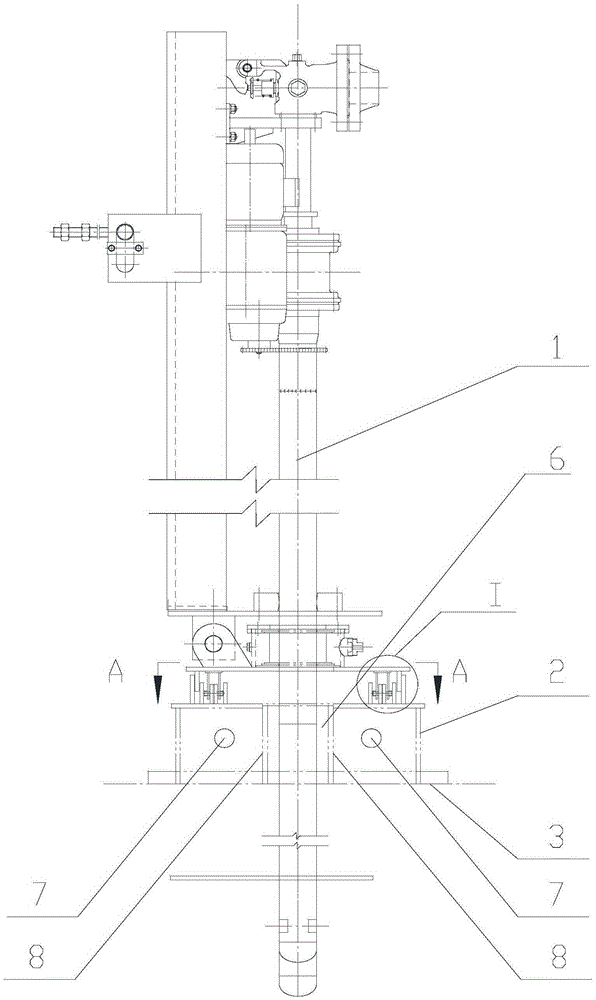

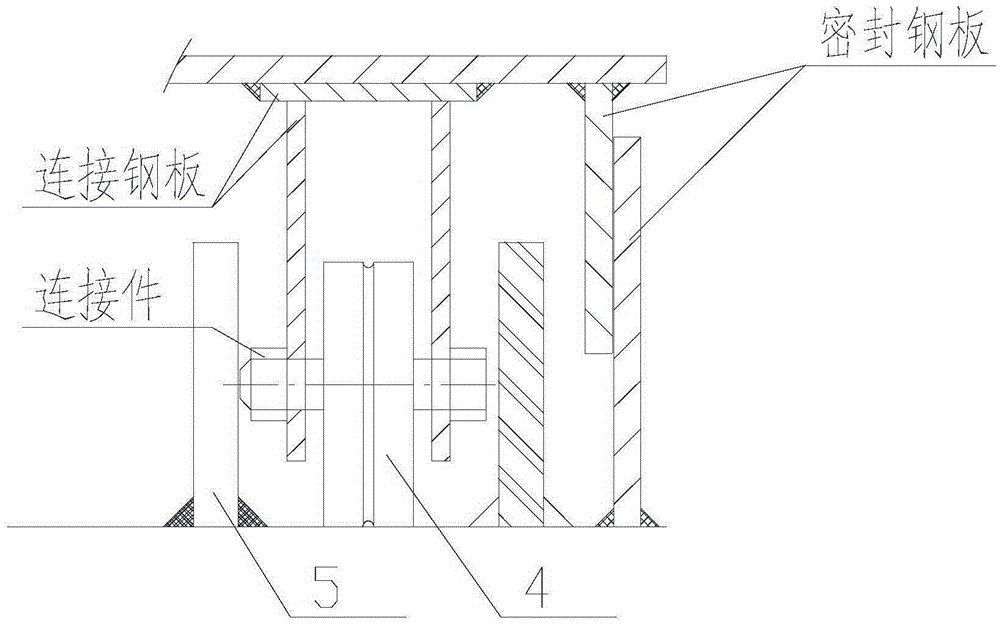

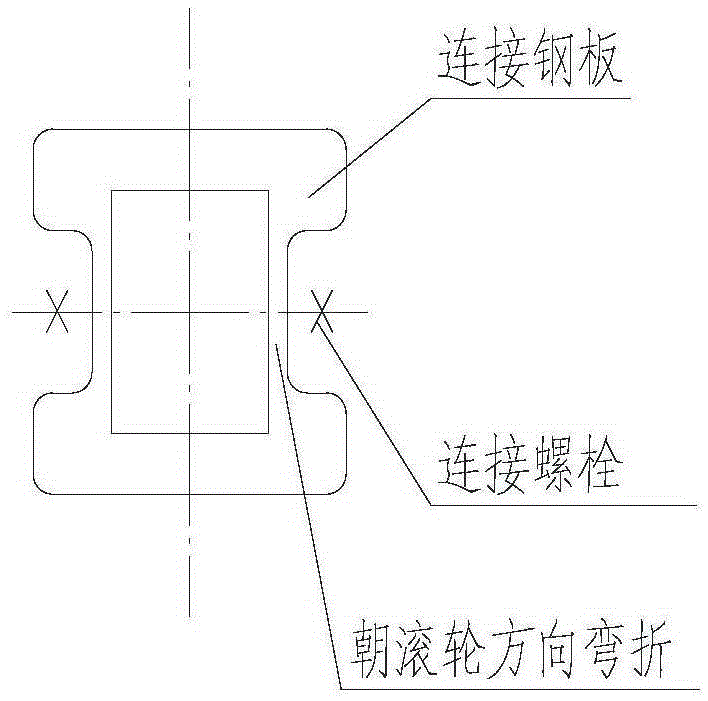

[0016] The heat exchanger steam soot blower includes a semi-telescopic soot blower 1, a soot blower support structure 2 and a flue top wall 3; the soot blower support structure 2 is arranged on the flue top wall 3; the flue There is a long notch on the wall 3 at the top of the channel. The soot blower support structure 2 is arranged on both sides of the notch and encloses a sealed air cavity 6. The soot blower support structure 2 is located on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com