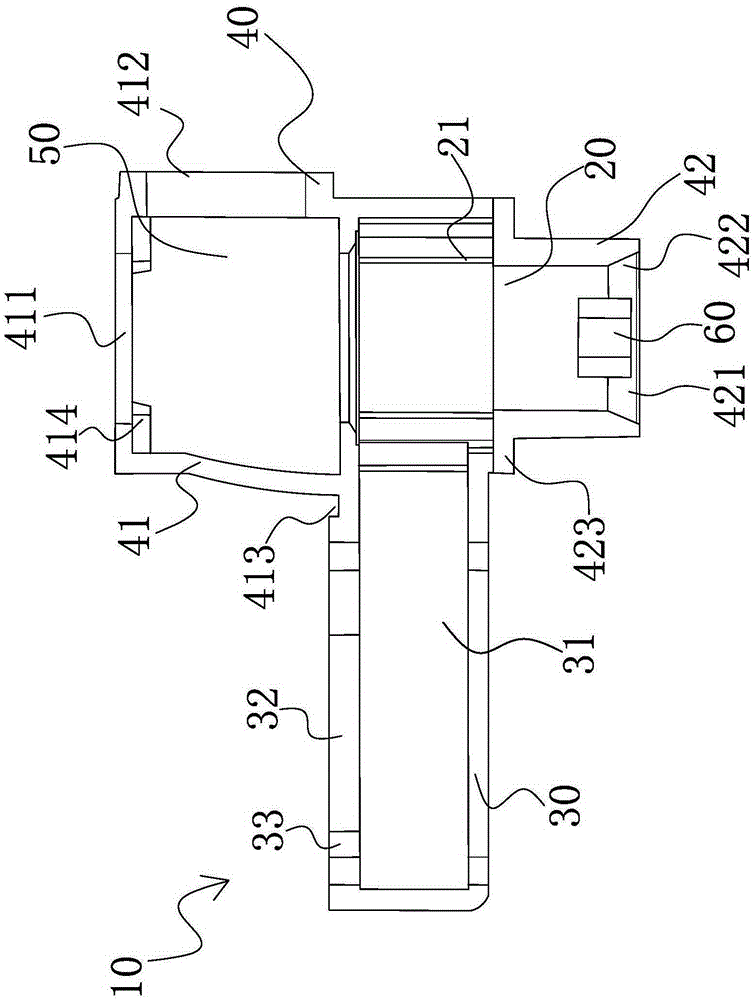

Electromagnetic valve suitable for air blower

A solenoid valve and blower technology, applied in the field of solenoid valves, can solve the problems of high production cost, short service life, and complexity, and achieve the effect of simple structure and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

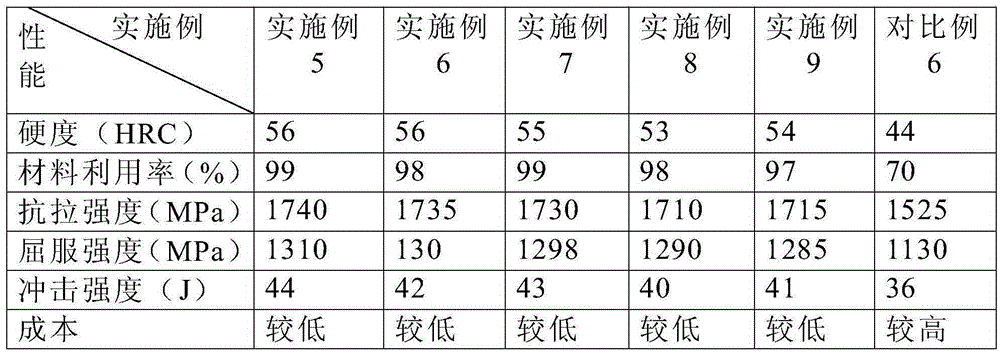

Examples

Embodiment 1

[0072]Weigh raw materials according to the following components and their weight percentages: epoxy resin E44: 50wt%; alkali-free glass fiber: 15wt%; compatibilizer: 4wt%; primary antioxidant: 0.4wt%; auxiliary antioxidant: 0.4wt %; processing aids: 2wt%; the balance is silicon dioxide.

[0073] Mix all the raw materials except the alkali-free glass fiber in the high-speed mixer at high speed, then melt the mixed raw materials through the twin-screw extruder and add the alkali-free glass fiber to the side feeding hopper of the twin-screw extruder, and extrude to make Granules, and finally the piston in the solenoid valve is made through ordinary processing and molding technology.

[0074] Wherein, the surface of the alkali-free glass fiber is coated with a graphene oxide coating with a thickness of 0.5 μm; the alkali-free glass fiber is chopped glass fiber, the length of the chopped glass fiber is 3 mm, and the diameter is 10 μm; Described silicon dioxide is the mixture that ...

Embodiment 2

[0076] Weigh raw materials according to the following components and their weight percentages: epoxy resin E44: 55wt%; alkali-free glass fiber: 10wt%; compatibilizer: 5wt%; primary antioxidant: 0.4wt%; auxiliary antioxidant: 0.4wt %; processing aids: 3wt%; the balance is silicon dioxide.

[0077] Mix all the raw materials except the alkali-free glass fiber in the high-speed mixer at high speed, then melt the mixed raw materials through the twin-screw extruder and add the alkali-free glass fiber to the side feeding hopper of the twin-screw extruder, and extrude to make Granules, and finally the piston in the solenoid valve is made through ordinary processing and molding technology.

[0078] Wherein, the surface of the alkali-free glass fiber is coated with a graphene oxide coating with a thickness of 0.6 μm; the alkali-free glass fiber is chopped glass fiber, the length of the chopped glass fiber is 2 mm, and the diameter is 12 μm. Described silicon dioxide is the mixture comp...

Embodiment 3

[0080] Weigh raw materials according to the following components and their weight percentages: epoxy resin E44: 40wt%; alkali-free glass fiber: 20wt%; compatibilizer: 3wt%; primary antioxidant: 0.3wt%; auxiliary antioxidant: 0.5wt %; processing aids: 2wt%; the balance is silicon dioxide.

[0081] Mix all the raw materials except the alkali-free glass fiber in the high-speed mixer at high speed, then melt the mixed raw materials through the twin-screw extruder and add the alkali-free glass fiber to the side feeding hopper of the twin-screw extruder, and extrude to make Granules, and finally the piston in the solenoid valve is made through ordinary processing and molding technology.

[0082] Wherein, the surface of the alkali-free glass fiber is coated with a graphene oxide coating with a thickness of 0.3 μm; the alkali-free glass fiber is chopped glass fiber, the length of the chopped glass fiber is 4.5 mm, and the diameter is 14 μm ; Described silicon dioxide is the mixture t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com