Overload protection clutch used for shaft connection

An overload protection and clutch technology, which is applied in clutches, automatic clutches, couplings, etc., can solve problems such as inconvenient assembly, and achieve the effects of simple structure, reduced tangential force, and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

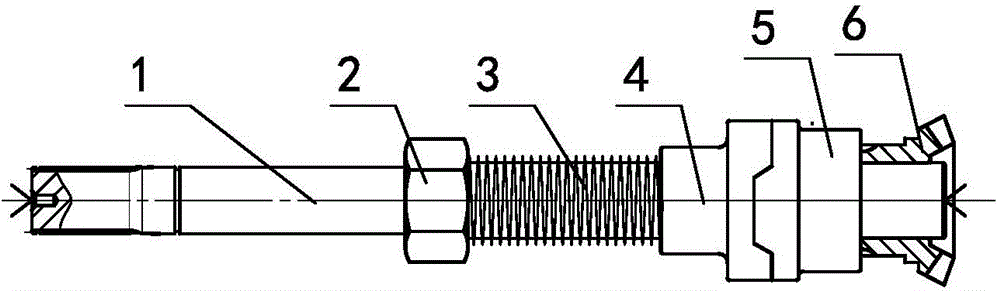

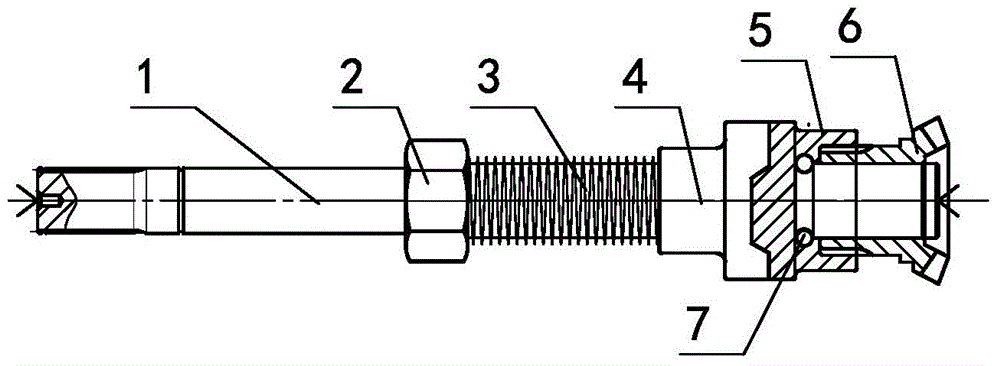

[0018] Such as figure 1 , figure 2 As shown, the overload protection clutch used for shaft connection includes mutually independent horizontally arranged shaft 1 and bevel teeth 6 mounted on shaft 1. On shaft 1, there is threaded nut 2, and nut 2 is right A clutch 4 for the power transmission of the shaft 1 is installed on the shaft 1 on the side, a spring 3 is sleeved on the shaft 1 between the clutch 4 and the nut 2, the left end of the spring 3 is pushed against the nut 2, and the right end is pushed against the nut 2 Clutch one 4, on the shaft 1 on the right side of the clutch one 4, a clutch two 5 that can rotate freely around the shaft 1 is installed, the clutch two 5 is connected with the clutch one 4 through the clutch claw, and the clutch two 5 is connected to the shaft 1 through the connotation ball 7 Carry out lateral positioning, bevel gear 6 left ends are connected on the clutch two 5 by spline.

[0019] In this embodiment, the bevel gear 6 is provided with ext...

Embodiment 2

[0022] A change is made on the basis of the first embodiment, and the clutch one 4 and the shaft 1 are fitted with a flat key; the natural length of the spring 3 is changed to 200mm. Others are the same as embodiment one.

Embodiment 3

[0024] A change is made on the basis of the first embodiment, and the natural length of the spring 3 is changed to 300mm. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com