Flat-bottom silo

A silo and flat bottom technology, applied in the field of silos, can solve the problems of resource waste, silo weight, and silo wall hanging, etc., and achieve the effect of reducing construction difficulty, reducing silo weight, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

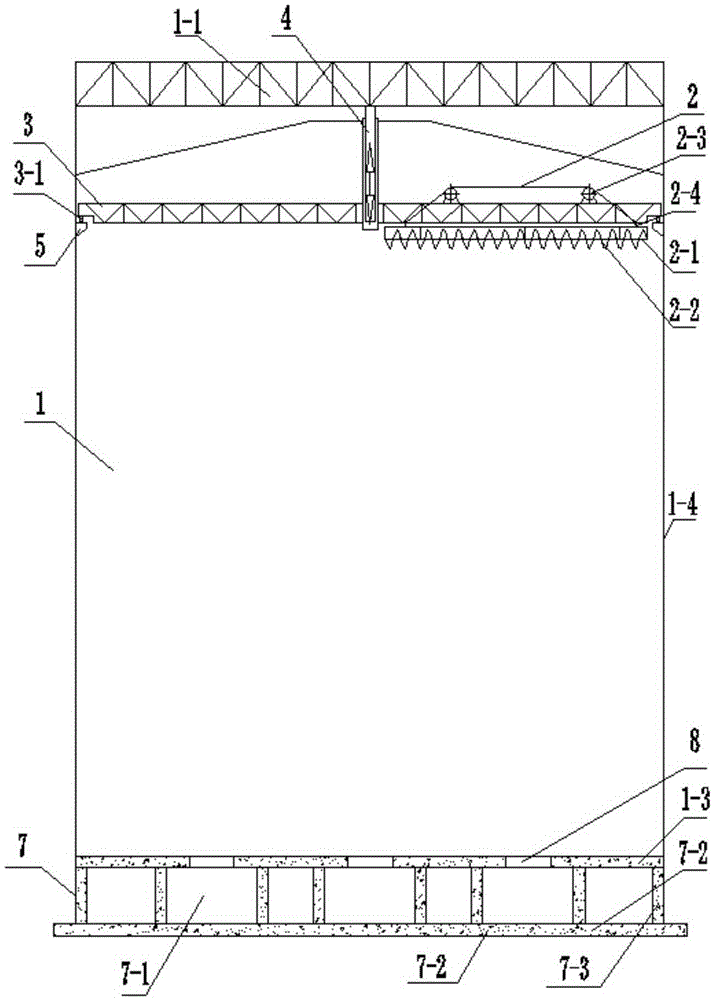

[0048] Such as figure 1As shown, a flat-bottomed silo includes a silo body 1, a revolving trestle 3, a silo support structure 7, a three-dimensional stacking and reclaiming mechanism 2 and a central material guide cylinder 4,

[0049] The silo body 1 has a material storage cavity, the revolving trestle 3 is horizontally arranged on the upper part of the material storage cavity, and the two ends of the revolving trestle 3 are slidably connected to the inner wall of the silo body 1 through a receiving device 5 The silo support structure 7 is installed at the bottom of the silo body 1; the three-dimensional stacking and reclaiming mechanism 2 is installed on the rotary trestle 3, and is located between the central material guide cylinder 4 and the silo Between the inner side walls of the main body 1, the central material guide cylinder 4 is vertically arranged between the middle part of the slewing trestle 3 and the top of the silo main body 1; there are three feeding corridors 7...

Embodiment 2

[0058] Such as figure 2 As shown, a flat-bottomed silo has the same basic structure as the first embodiment, and the difference from the first embodiment is that there are three conveying corridors 7-1 in the silo support structure 7; the silo floor 1- 3 is provided with nine discharge ports 8, and the nine discharge ports 8 are distributed in an array on the warehouse floor 1-3, wherein each conveying corridor 7-1 corresponds to three discharge ports 8; The three-dimensional stacking and reclaiming mechanism 2 has two groups, and the three-dimensional stacking and reclaiming mechanism 2 of the two groups is symmetrically arranged on the rotary truss 2-1 on both sides of the central material guide cylinder 4; the connecting piece 2-4 It is a steel wire rope, one end of the steel wire rope is fixedly connected to the output end of the hoisting mechanism 2-3, and the other end is fixed on the truss.

Embodiment 3

[0060] Such as image 3 As shown, a flat-bottomed silo has the same basic structure as the first embodiment, and the difference from the first embodiment is that there are three conveying corridors 7-1 in the silo support structure 7; the silo floor 1- 3 is provided with nine discharge ports 8, and the nine discharge ports 8 are distributed in an array on the warehouse floor 1-3, wherein each conveying corridor 7-1 corresponds to three discharge ports 8; The central material guide cylinder 4 is a fixed material guide cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com