Yeast-block vibrating and slurry extracting device

A bending block and vibration transmission technology, which is applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical instruments, etc., can solve the problems of heavy labor and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

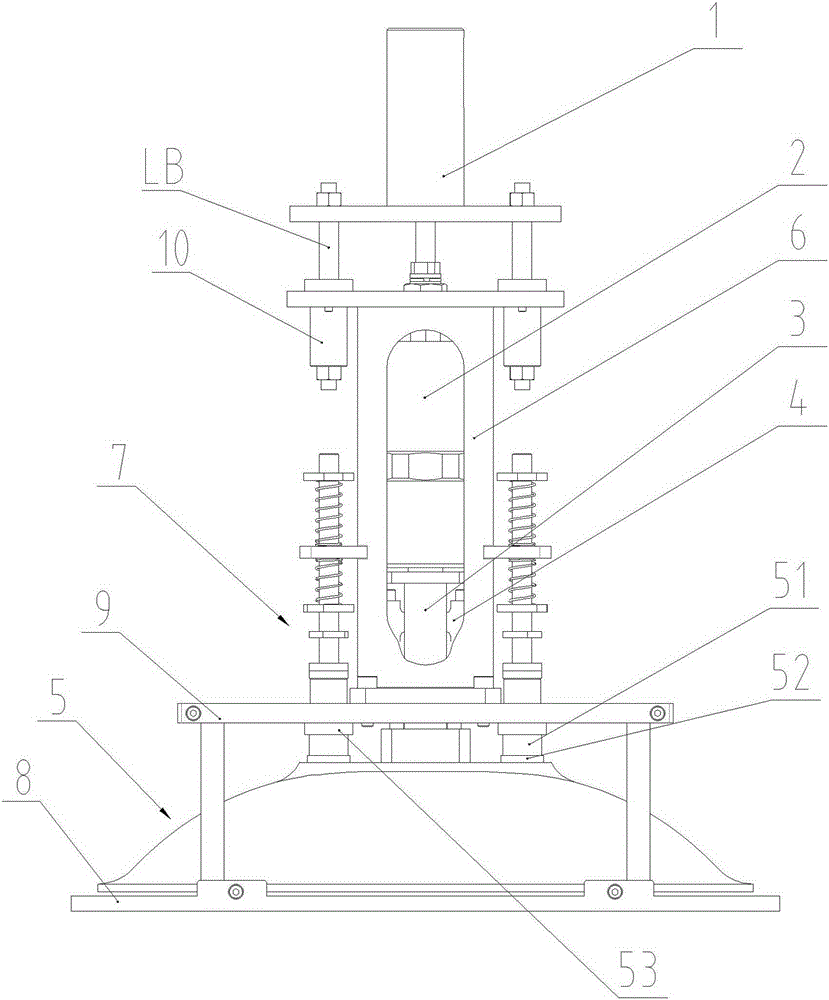

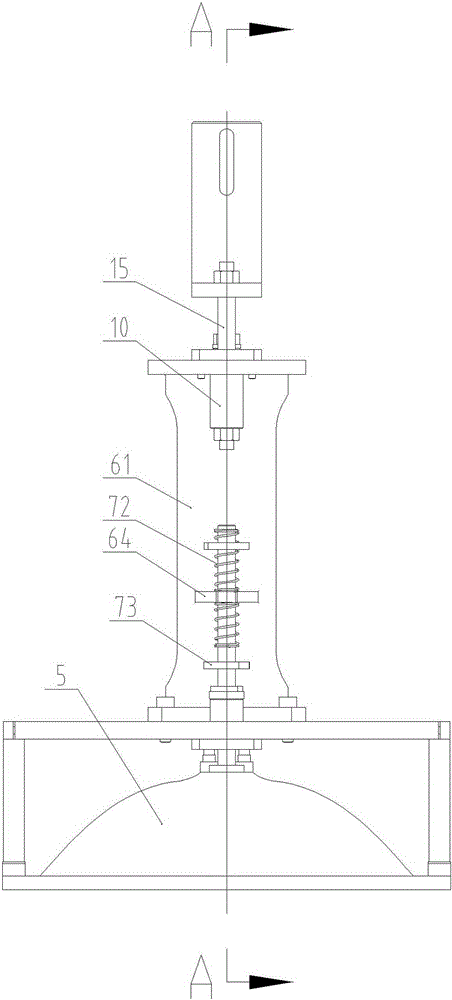

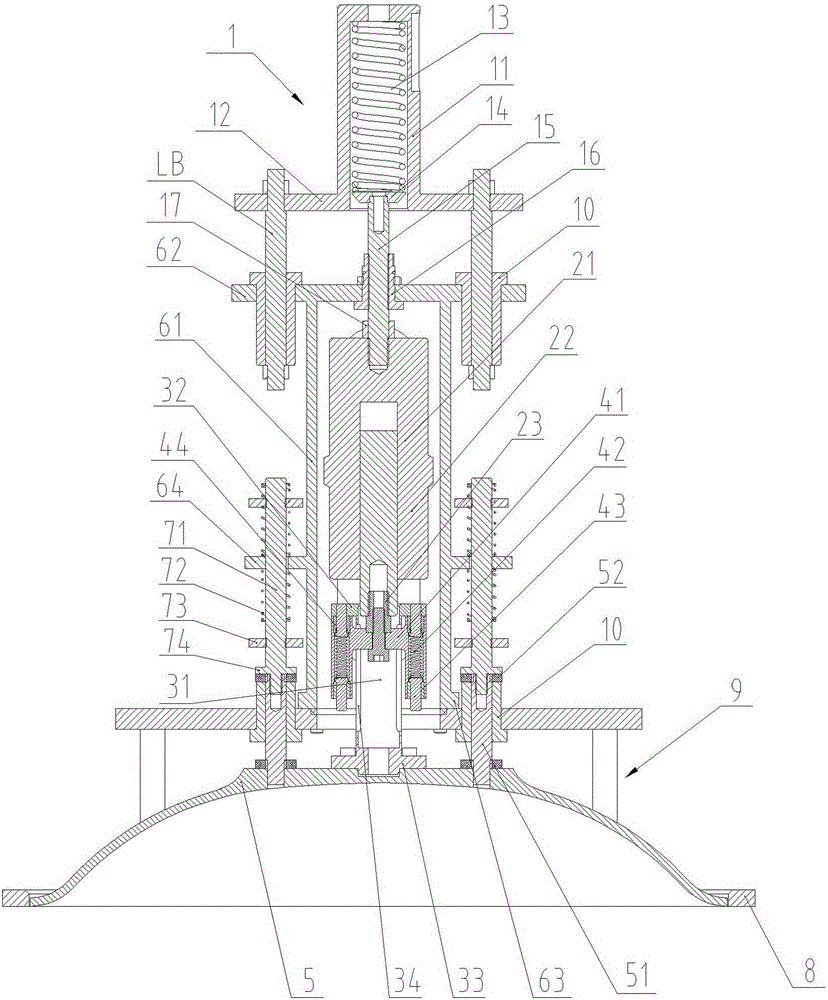

[0020] like Figure 1 to Figure 4 As shown, this embodiment discloses a curved block vibrating pulping device, including a fixed connector 1, a pneumatic vibrator 2, a vibration transmission shaft assembly 3, a blocking block assembly 4, a vibration shaping die 5, a strut 6, and an elastic buffer assembly. 7. Press frame 8, table-type fixing frame 9, and elongated flange linear bearing 10.

[0021] The pressing frame 8 is a rectangular frame, and the vibration shaping mold 5 is a turtle-back-shaped cover body in the middle of the rectangular bottom edge, which is fixed in the inner cavity of the pressing frame 8 with the bottom edge, and the table-type fixing frame 9 is connected to the upper side of the pressing frame 8. The top plate of the mold holder 9 is located above the top of the vibration shaping die 5 .

[0022] Two upward connecting shafts 51 are connected to both ends of the top of the vibration shaping die 5 in the length direction, and a flanged linear bearing 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com